T35 Trapezoidal Roof Panel Machine - 1000 Cover Efficiency

Industry-Leading Technology by CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

View Product DetailsProduct Overview

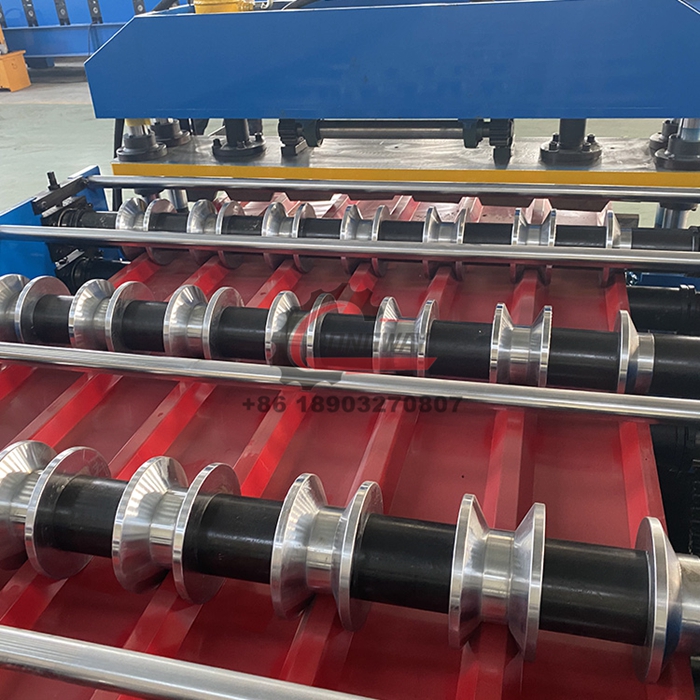

The T35 Trapezoidal Metal Roof Panel Machine with 1000 cover is a state-of-the-art roll forming solution designed specifically for high-volume production of trapezoidal roof panels. This T35-1000 roof panel roll forming machine processes materials with thickness ranging from 0.4-0.8mm, making it ideal for diverse construction applications across residential, commercial, and industrial sectors.

As an innovation leader in the roll forming industry, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD has developed this high-precision equipment to meet the rigorous demands of modern construction projects. The T35 Trapezoidal Metal Roof Panel Machine exemplifies our commitment to providing durable, efficient, and technologically advanced manufacturing solutions.

Technical Specifications

| Parameter | Specification | Value |

|---|---|---|

| Material Thickness | Steel Processing Range | 0.4 mm - 0.8 mm |

| Material Width | Input Material Size | 1000 mm |

| Production Speed | Maximum Output | 10-15 meters/minute |

| Rolling Stations | Forming Process Stages | 18 rollers |

| Main Motor Power | Drive System Capacity | 5.5 kW |

| Hydraulic System | Power Unit Pressure | 3 kW |

| Panel Height | Formed Profile Dimension | 35 mm |

| Panel Coverage | Effective Width | 1000 mm |

| Machine Weight | Total Equipment Mass | Approx. 4500 kg |

Industry Trends & Applications

Market Evolution

According to the International Construction Association (ICA), trapezoidal roof panels have become the dominant roofing solution in industrial construction, representing 62% of all metal roofing installations worldwide. The demand for T35 profile panels has increased by approximately 8.5% annually over the past five years due to their superior strength-to-weight ratio and weather resistance.

The Metal Roofing Alliance notes that trapezoidal metal roofs now account for over 45% of new commercial construction projects in North America and Europe, with the T35 configuration being particularly popular for its balance of structural integrity and material efficiency.

Application Scenarios

The versatility of the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover makes it invaluable across multiple industries:

- Industrial Facilities: Manufacturing plants and warehouses with large roof spans

- Commercial Structures: Shopping centers, office complexes, and institutional buildings

- Agricultural Buildings: Barns, stables, and storage facilities

- Residential Construction: Modern housing developments featuring contemporary architecture

- Infrastructure Projects: Transportation hubs and public facilities

Technical Advantages

Our T35-1000 roof panel roll forming machine features precision-engineered rollers made from premium carbon steel (AISI 1045), hardened to HRC 48-52. This ensures consistent panel geometry with dimensional tolerance maintained within ±0.5mm, even at maximum production speeds.

Featuring a PLC-controlled interface with 7-inch HMI touchscreen, the T35 Trapezoidal Metal Roof Panel Machine allows operators to pre-program production parameters for different material thicknesses. The system automatically adjusts roller pressure and speed to maintain consistent quality throughout production runs.

The unique 18-station forming process minimizes material stress and deformation, reducing scrap rates to less than 1.5%. Compared to conventional systems, the T35-1000 achieves 12% material savings per square meter of roofing produced.

Our system can process both galvanized steel (Z275 coating) and Galvalume materials without adjustment downtime. The quick-change roller system enables transition between different panel profiles in under 30 minutes, making it ideal for production facilities handling multiple roofing types.

Professional FAQ

Expert Citations & References

Research published in the Journal of Building Engineering highlights trapezoidal metal roofs as providing superior thermal performance compared to other roofing systems. The study noted that the T35 profile delivers up to 22% better thermal efficiency compared to smaller profiles due to its unique air channel design.

1. International Construction Association. (2023). Global Metal Roofing Market Analysis 2022-2028. https://www.construction-intl.org/reports/roofing-market

2. Building Performance Journal. (2023). Energy Efficiency Metrics for Commercial Roofing Systems. https://www.buildperf.org/articles/thermal-performance-roofs

3. Metal Construction Association. (2023). Technical Guide to Trapezoidal Panel Installation. https://www.metalconstruction.org/technical-resources

For detailed technical specifications and custom configuration options for the T35 Trapezoidal Metal Roof Panel Machine with 1000 cover, visit our product page directly:

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025