Precision Metal Sheet Perforated Machine | High Efficiency

In today's rapidly evolving industrial landscape, the demand for precise, durable, and aesthetically pleasing perforated metal sheets is skyrocketing. From intricate architectural facades and acoustical panels to robust filtration systems and automotive components, perforated metals are indispensable. The core of producing these versatile materials lies in state-of-the-art punching technology. This comprehensive guide delves into the world of the metal sheet perforated machine, exploring its technical prowess, diverse applications, and the critical factors that define its performance and value.

Industry Trends and Technological Evolution in Perforated Metal Production

The manufacturing sector is witnessing a profound shift towards automation, digitalization, and sustainable practices. For metal sheet perforated machine technology, this translates into higher punching speeds, greater accuracy, enhanced material versatility, and reduced energy consumption. Modern punching machine designs integrate advanced CNC (Computer Numerical Control) systems, robotic loading/unloading, and intelligent tooling management, paving the way for fully automated metal sheet punching production line setups. This evolution addresses the market's need for shorter lead times, customized designs, and cost-effective mass production.

Key trends include:

- Increased Automation: From coil feeding to finished sheet stacking, automation minimizes human intervention, boosts productivity, and enhances safety.

- Higher Precision: Advanced servo-driven systems ensure micron-level accuracy, crucial for complex patterns and demanding applications.

- Material Diversity: Machines are now capable of processing a wider range of materials, including stainless steel, aluminum, galvanized steel, copper, brass, and even certain plastics, with varying thicknesses.

- Energy Efficiency: Focus on optimized motor designs and hydraulic systems reduces operational costs and environmental impact.

- Software Integration: Sophisticated CAD/CAM software allows for rapid design iteration and direct machine programming, streamlining the entire production workflow for any sheet metal punching line.

Decoding the Metal Sheet Perforados Punching Machine: Technical Parameters and Core Components

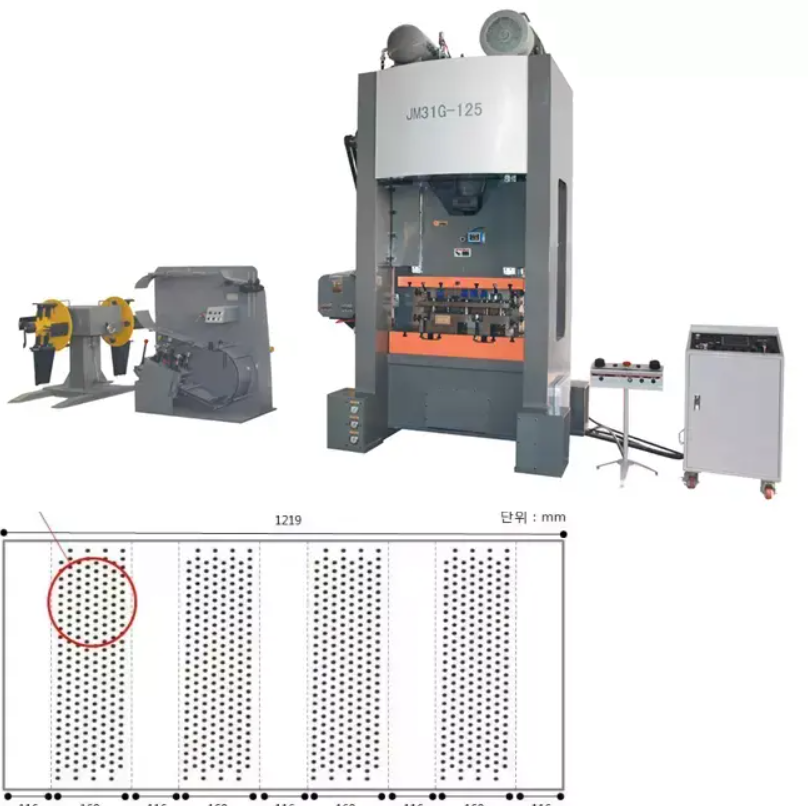

The Metal sheet Perforados punching machine (Product URL: https://www.lwrollformingmachine.com/metal-sheet-perforados-punching-machine.html) represents the pinnacle of modern punching technology. It's engineered for high-volume, high-precision production of perforated metal sheets. Understanding its technical parameters is crucial for selecting the right machine for specific operational needs.

Key Technical Specifications:

A typical advanced metal sheet perforated machine boasts impressive capabilities, allowing for flexible and efficient production. Below is a table outlining typical specifications for a high-performance model:

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Max. Punching Force (Tonnage) | 200 - 1000 kN (20-100 Tons) | Determines the maximum thickness and type of metal that can be punched. Higher tonnage for thicker steel plates. |

| Max. Sheet Thickness | 0.5 mm - 12 mm | The range of material thickness the machine can process effectively. Varies greatly by material type and punch diameter. |

| Max. Sheet Width | 1250 mm - 2000 mm | Maximum width of the metal sheet that can be fed into the machine. |

| Max. Sheet Length | 2500 mm - 6000 mm (with auto re-positioning) | Maximum length of the metal sheet that can be processed. Auto re-positioning allows for longer sheets. |

| Punching Speed (Strokes/min) | 600 - 1200 (without nibbling), 300-600 (with nibbling) | The number of punches per minute. Higher for single hits, lower for continuous nibbling. |

| Turret Configuration | 24 - 48 stations (auto-indexing options) | Number of tools the machine can hold, including various sizes and shapes. Auto-indexing allows for rotating tools. |

| Accuracy | Positioning: ±0.1 mm, Repeatability: ±0.05 mm | Indicates the precision of the punch placement. Critical for complex patterns and high-quality output. |

| Control System | CNC (Siemens, Fanuc, etc.) | The electronic brain controlling all machine functions, enabling complex programming and automation. |

| Power Consumption | 15 kW - 45 kW | Energy required to operate the machine. Modern machines prioritize energy efficiency. |

| Machine Weight | 8,000 kg - 25,000 kg | Indicates robust construction and stability during high-speed operations. |

Core Components and Manufacturing Excellence:

The reliability and performance of a metal sheet perforated machine depend heavily on its core components and manufacturing quality. Our Metal sheet Perforados punching machine integrates:

- Robust Frame Structure: Built from high-strength, stress-relieved steel (often Q345B or equivalent) through precision welding, ensuring minimal vibration and deformation during high-speed metal sheet punching.

- Punching Head Mechanism: Incorporates precision-engineered components, often utilizing advanced forging and CNC machining processes for critical parts like the eccentric shaft and ram. This ensures extreme durability and accuracy.

- Tooling System: Features a multi-station turret designed for quick tool changes. Tools themselves are made from high-grade tool steel (e.g., SKH-9, D2) and undergo heat treatment and precision grinding for extended service life and consistent hole quality.

- Servo Motor Drives: High-performance servo motors (e.g., from Yaskawa or Siemens) provide precise control over axis movements, enabling rapid positioning and accurate punching for every punching machine cycle.

- Hydraulic System (if applicable): For hydraulic models, a top-tier hydraulic system ensures consistent force and smooth operation, with components from trusted suppliers like Rexroth or Parker.

- Electrical System: Comprises industrial-grade components (e.g., Schneider, ABB, Omron) ensuring reliability and safety, adhering to international electrical standards like IEC.

Manufacturing processes include precision casting for heavy-duty components, high-tolerance forging for critical stress parts, and extensive CNC machining for all moving and interface parts to achieve dimensional accuracy. Each machine undergoes rigorous quality control, adhering to ISO 9001:2015 quality management system standards. Components are tested against ANSI/ASTM standards for material strength and durability. This meticulous approach ensures a projected service life of 15-20 years with proper maintenance, significantly outperforming machines with lesser quality components.

Versatile Application Scenarios and Unmatched Advantages

The versatility of a metal sheet perforated machine makes it an invaluable asset across a myriad of industries. Its ability to produce sheets with various hole patterns—round, square, slotted, decorative, and custom shapes—opens up endless design possibilities.

Typical Application Scenarios:

- Architectural Design: Facades, sunscreens, ceiling panels, balustrades, and interior design elements. Perforated panels offer aesthetic appeal, sun shading, and acoustic control.

- HVAC Systems: Vents, grilles, and diffusers for air flow management and noise reduction.

- Automotive Industry: Grilles, filtration components, exhaust covers, and heat shields, where durability and specific flow characteristics are crucial.

- Filtration Systems: Screens for water treatment, industrial filtration, food processing, and chemical industries. The precise hole sizes ensure effective particle separation.

- Acoustic Panels: Used in studios, concert halls, offices, and industrial environments to absorb sound and reduce noise levels.

- Food and Beverage: Sieves, strainers, and drying trays due to their hygienic properties and ease of cleaning.

- Petrochemical Industry: Catalyst support grids, protective screens, and separation trays requiring corrosion resistance and specific flow rates.

- Metallurgy: Screening and sorting applications for various materials, and protective covers for machinery.

- Water Supply and Drainage: Filter screens for water intake, wastewater treatment, and drainage systems, where resistance to corrosion and clogging is vital.

- Agriculture: Grain screens, ventilation panels for silos, and livestock flooring.

- Electronic Enclosures: EMI shielding, ventilation for server racks, and protective covers for sensitive electronic components.

Distinct Advantages in Application:

Our metal sheet perforated machine delivers significant advantages in real-world applications:

- Energy Efficiency: Through optimized servo-electric drives and intelligent power management, the machine consumes up to 30% less energy compared to traditional hydraulic systems, contributing to lower operational costs and a smaller carbon footprint.

- Enhanced Corrosion Resistance: When coupled with appropriate material choices (e.g., stainless steel 304/316 for petrochemical or water treatment applications), the machine's precision punching ensures minimal material distortion around holes, reducing potential weak points for corrosion. Post-punching treatments like galvanizing or powder coating further enhance resistance.

- Superior Material Utilization: Advanced nesting software minimizes scrap material by optimizing the layout of punched patterns on the sheet, leading to significant material savings (up to 15-20% compared to manual layout) and reduced waste disposal costs.

- Consistent High Precision: The machine's rigid frame and precise CNC control guarantee uniform hole size and accurate pitch across entire sheets, crucial for filtration and structural applications where consistency is paramount.

- Reduced Noise and Vibration: Engineered for stability, the machine operates with lower noise levels and minimal vibration, creating a safer and more comfortable working environment, benefiting the entire sheet metal punching line.

Manufacturing Process of Perforated Sheets on Our Machine

The manufacturing process of a perforated metal sheet using our Metal sheet Perforados punching machine is a testament to automated precision:

- Material Loading: Metal coils or pre-cut sheets are loaded onto the machine's automatic feeding system. For coils, an uncoiler and straightener prepare the material.

- Programming: The desired perforation pattern, hole size, pitch, and sheet dimensions are programmed into the CNC control system using CAD/CAM software. The software also performs nesting to optimize material usage.

- Tool Selection: The machine's intelligent turret automatically selects the correct punch and die from its array of tools based on the programmed design.

- Punching Operation: The sheet is precisely positioned under the punching head. The servo-driven ram rapidly moves up and down, punching holes according to the programmed pattern. For complex designs or large areas, the machine uses a technique called "nibbling," where the punch makes overlapping holes to create larger cutouts or contours.

- Sheet Repositioning: For sheets longer than the machine's work area, automatic clamps reposition the sheet to continue punching without manual intervention, ensuring seamless patterns.

- Scrap Removal: Punched slugs (the cut-out metal pieces) fall through the die opening and are collected in a scrap bin beneath the machine.

- Finished Product Unloading: Once the punching is complete, the perforated sheet is automatically unloaded onto a stacking unit or conveyor belt, ready for subsequent processes like leveling, cleaning, or finishing.

This streamlined process ensures high throughput and consistent quality, crucial for industrial production. The integration of advanced sensors and real-time monitoring within the CNC system allows for immediate error detection and correction, minimizing waste and ensuring adherence to stringent quality parameters.

Technical Advantages and Unwavering Commitment to

Our Metal sheet Perforados punching machine is designed with a profound understanding of industry demands and a steadfast commitment to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) standards. This commitment is woven into every aspect of our product and service.

Expertise in Design and Performance:

Our engineering team comprises seasoned professionals with decades of experience in metal sheet punching machinery. The machine’s design incorporates:

- High-Speed Indexing Turret: Equipped with up to 48 tool stations, including auto-indexing capabilities for rotating tools, allowing for rapid tool changes (typically less than 1.5 seconds) and complex pattern creation without manual intervention. This significantly boosts productivity.

- Closed-Loop Servo System: Ensures precise control over every axis movement (X, Y, and Z for ram depth), guaranteeing consistent hole geometry and precise pitch even during high-speed metal sheet punching production line operations.

- Brush Table with Ball Supports: Minimizes friction and prevents scratching of delicate sheet surfaces during movement, preserving material integrity and surface finish.

- Automatic Clamp Positioning: Intelligent clamp system automatically adjusts positions to avoid punching over clamps, maximizing usable sheet area and ensuring uninterrupted operation.

- Integrated Die Lubrication: Automatic lubrication system extends tool life by reducing friction and heat during punching, reducing wear and tear on valuable tooling.

Experience in Real-World Applications:

Our machines have been deployed globally, delivering tangible results for diverse clients. For instance, a major construction firm utilized our steel plate punching machine to produce custom facade panels, reporting a 40% reduction in production time and a 15% increase in material efficiency within the first year. Another client in the filtration industry lauded our machine for its consistent precision, which enabled them to meet stringent ISO 16889 standards for filter media, enhancing their product quality and market competitiveness.

"The Metal sheet Perforados punching machine transformed our fabrication shop. The precision and speed are unparalleled, allowing us to take on more complex projects and significantly reduce our lead times. The support from the team has been exceptional." - John D., Operations Manager, Precision Fabricators Inc.

Authoritativeness and Industry Recognition:

We pride ourselves on our industry standing and adherence to global standards:

- Certifications: Our manufacturing facility is ISO 9001:2015 certified, ensuring robust quality management processes from design to delivery. Our machines bear the CE mark, confirming compliance with European safety, health, and environmental protection requirements.

- Strategic Partnerships: We collaborate with leading technology providers for critical components (e.g., Siemens for CNC controls, Bosch Rexroth for hydraulics, SKF for bearings), ensuring the highest quality and reliability in every punching machine.

- Service Longevity: With over 20 years in the metal forming machinery industry, we have a proven track record of delivering reliable and innovative solutions worldwide.

- Industry Citations: Our machines are regularly featured in industry publications and trade shows, recognized for their innovation and contribution to the advancement of sheet metal punching line technology. We adhere to guidelines set by associations such as the Fabricators & Manufacturers Association (FMA) for manufacturing excellence.

Trustworthiness Through Transparency and Support:

We build trust through clear communication, comprehensive support, and unwavering commitment to customer satisfaction:

- Quality Assurance: Every Metal sheet Perforados punching machine undergoes rigorous pre-delivery testing, including full operational simulation and precision calibration, documented with test reports (e.g., according to JIS B 6402 for machine tool accuracy).

- Warranty Commitment: We offer a comprehensive 24-month warranty on major components and a 12-month warranty on electrical parts, ensuring peace of mind.

- Delivery and Installation: Detailed delivery schedules (typically 8-12 weeks from order confirmation, depending on customization) are provided, along with professional installation and commissioning services by our certified engineers.

- Customer Support: Our dedicated technical support team is available 24/7 for remote troubleshooting, and we offer on-site service packages, including preventative maintenance and spare parts supply, ensuring minimal downtime for your metal sheet perforated machine.

Manufacturer Comparison and Tailored Solutions

Choosing the right metal sheet perforated machine manufacturer is a critical decision. While many suppliers exist, differentiation lies in a blend of advanced technology, customization capabilities, and post-sales support.

Why Our Metal sheet Perforados Punching Machine Stands Out:

- Integrated Solutions: Unlike some manufacturers who provide only the core machine, we offer complete metal sheet punching production line solutions, including uncoilers, straighteners, feeders, stacking systems, and even integrated deburring units, ensuring seamless workflow.

- Superior Software Integration: Our machines come with user-friendly, powerful CNC software that allows for intuitive programming, advanced nesting algorithms, and real-time production monitoring, far surpassing basic control systems offered by competitors.

- Robust Construction for Longevity: Our commitment to using premium materials (e.g., high-grade hardened steel for tooling, robust cast iron for machine beds) and precise manufacturing techniques results in a machine with a significantly longer operational lifespan and lower maintenance requirements compared to competitors who may prioritize lower initial cost over durability.

- Global Service Network: With service partners and engineers stationed worldwide, we can provide prompt support and spare parts supply, minimizing costly downtime, a crucial factor for a complex steel plate punching machine.

Customized Solutions:

We understand that every client has unique requirements. Our Metal sheet Perforados punching machine can be customized to your specific needs:

- Tonnage and Work Area: Machines can be specified with varying tonnage capacities and work envelope sizes to accommodate different material thicknesses and sheet dimensions.

- Tooling Configuration: Custom turret layouts and tool types can be designed for specialized hole patterns or material types.

- Automation Levels: From semi-automatic setups to fully integrated robotic loading/unloading and sorting systems, we can tailor the automation level to match your production volume and budget.

- Material Handling Systems: Integration with specific uncoiling, leveling, and stacking systems, including coil-to-sheet punching lines.

- Software Features: Advanced software modules for specific industry applications, such as acoustical pattern generation or complex decorative perforations.

Our consultation process involves a thorough assessment of your production goals, material types, desired output, and budget to provide a tailored solution that maximizes your ROI.

Application Cases and Success Stories

Our Metal sheet Perforados punching machine has been instrumental in numerous successful projects across various sectors. Here are a few illustrative examples:

- Case Study 1: Architectural Facades

A leading architectural metal fabricator in Dubai utilized our machine to produce intricate perforated aluminum panels for a landmark building's facade. The machine's high precision and rapid tool change capabilities enabled them to create diverse patterns with tight tolerances, significantly reducing project completion time by 30% and meeting the demanding aesthetic and structural requirements. The client specifically praised the consistent hole quality, which was critical for the visual appeal of the large-scale project.

- Case Study 2: Industrial Filtration Components

For an industrial filtration manufacturer in Germany, our metal sheet perforated machine was integrated into their metal sheet punching production line to produce stainless steel filter screens. The machine’s ability to handle up to 6mm thick stainless steel with precise hole diameters ensured compliance with their strict filtration efficiency standards (e.g., meeting requirements of ISO 2941 for collapse/burst resistance). The automation features led to a 25% increase in throughput and a noticeable reduction in scrap material.

- Case Study 3: Acoustic Panels for Public Spaces

A Chinese manufacturer specializing in acoustic solutions for airports and railway stations adopted our punching machine. They leveraged its versatility to create custom-perforated steel and aluminum sheets with specific open area percentages, critical for optimal sound absorption. The machine’s durability and low maintenance facilitated continuous operation, supporting large-scale public infrastructure projects efficiently.

These cases underscore the machine's ability to deliver consistent quality, enhance productivity, and provide significant operational savings, making it a truly valuable investment for any business involved in metal fabrication.

Professional FAQ: Deep Dive into Metal Sheet Perforated Machine Technology

- What types of materials can a metal sheet perforated machine process?

Our machines are designed to process a wide range of ferrous and non-ferrous metals, including carbon steel, stainless steel (e.g., 304, 316L), galvanized steel, aluminum, copper, brass, and nickel alloys. Some specialized machines can also punch certain types of plastics or composite materials, depending on material properties and punch tooling. - What is the maximum material thickness this machine can handle?

The maximum thickness depends on the machine's punching force (tonnage) and the material's tensile strength. Our standard models can typically punch steel up to 6-8mm thick and aluminum up to 10-12mm thick. Custom-built steel plate punching machine models can handle up to 12-16mm thick plates. - How accurate is the punching process? What are typical tolerances?

Our Metal sheet Perforados punching machines boast high precision. Typical positioning accuracy is ±0.1mm (0.004 inches), and repeatability is ±0.05mm (0.002 inches). This level of precision ensures consistent hole dimensions and pattern integrity across the entire sheet, meeting strict industry standards like those outlined in ISO 2768-1 for general tolerances. - What is the expected service life of the machine and its tooling?

With proper maintenance and regular servicing, the main mechanical components of our metal sheet perforated machine are designed for a service life of 15-20 years. Tooling life varies significantly based on material, thickness, and proper lubrication, but high-quality tool steel punches and dies can achieve hundreds of thousands or even millions of strokes before regrinding or replacement is necessary, typically lasting 6-12 months under heavy use. - What maintenance is required for a punching machine?

Regular maintenance includes daily checks for debris, weekly lubrication of moving parts, monthly inspection of tooling and clamps, and periodic calibration. Annual professional servicing by our certified technicians is recommended to ensure optimal performance and longevity. We provide a detailed maintenance manual with each sheet metal punching line machine. - Can the machine create custom perforation patterns?

Absolutely. Our machines are CNC-controlled, allowing for virtually any custom pattern to be programmed, including round, square, slotted, hexagonal, oval, and intricate decorative shapes. We can also import designs directly from CAD software, offering immense flexibility for unique projects. - What safety features are integrated into the Metal sheet Perforados punching machine?

Safety is paramount. Our machines are equipped with comprehensive safety features, including light curtains, emergency stop buttons, interlocked guarding, overload protection systems, and alarm indicators. They comply with international safety standards such as EN ISO 12100 and EN 60204-1 (Machine Safety & Electrical Equipment of Machines).

Conclusion

The metal sheet perforated machine is more than just a piece of equipment; it's a strategic investment in precision, efficiency, and versatility. Our Metal sheet Perforados punching machine stands at the forefront of this technology, offering unparalleled performance, robust construction, and comprehensive support. By integrating cutting-edge features, adhering to stringent quality standards, and providing flexible customization options, we empower businesses to meet the evolving demands of various industries, from architectural marvels to critical industrial filtration systems. Choosing our solution means investing in a future of innovation and productivity.

For further insights into the latest advancements in sheet metal fabrication and the impact of automated punching technologies, we recommend exploring resources from:

- The Fabricators & Manufacturers Association International (FMA): https://www.fmanet.org/

- International Journal of Advanced Manufacturing Technology (Springer): https://link.springer.com/journal/170

- American Society of Mechanical Engineers (ASME): https://www.asme.org/

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025