Automatic 988 Corrugated Roofing Sheet Roll Forming Machine

Unveiling the 988 Corrugated roofing sheet forming machine: A Pillar of Modern Construction

In the rapidly evolving landscape of industrial manufacturing and construction, the demand for efficient, durable, and high-precision machinery is paramount. Among the sophisticated equipment pivotal to the architectural and infrastructure sectors, the 988 Corrugated roofing sheet forming machine stands out as a critical innovation. This specialized machinery is engineered to produce corrugated metal roofing sheets, a fundamental component in various structural applications, from industrial warehouses and agricultural facilities to commercial buildings and residential roofing. The unique profile of the 988 corrugated sheet, characterized by its distinctive wave pattern and optimal depth, provides superior load-bearing capabilities, enhanced water drainage, and significant aesthetic appeal, making it a preferred choice for architects and builders globally. The evolution of this technology has been driven by increasing market demands for cost-effectiveness, material optimization, and expedited construction timelines. Industry trends indicate a consistent shift towards automated, intelligent, and energy-efficient roll forming solutions, reducing manual labor, minimizing material waste, and improving overall operational safety. Furthermore, the global emphasis on sustainable building practices has pushed manufacturers to innovate with machines capable of processing a wider range of environmentally friendly materials, including recycled steel and advanced coated alloys, thereby contributing to greener construction. This machine's robust design and precision engineering address the complex challenges faced by fabricators, ensuring consistent product quality, high output rates, and reduced operational costs. Its significance extends beyond mere production, impacting the entire supply chain by enabling faster project completion and more resilient infrastructure development. The integration of advanced control systems and diagnostic tools ensures peak performance and simplifies maintenance, contributing to an extended operational lifespan and reliable service. The growing adoption of such advanced roll forming technology underscores its indispensable role in meeting the dynamic needs of the modern construction industry, reinforcing its position as a cornerstone of progress and efficiency. The ongoing research and development in materials science and automation continue to enhance the capabilities of these machines, promising even greater efficiencies and adaptability in the future. This introduction sets the stage for a comprehensive exploration of the 988 machine's capabilities, its technical prowess, diverse applications, and the tangible benefits it brings to the global construction sector, firmly establishing its reputation as a benchmark for excellence in roll forming technology.

The contemporary construction paradigm emphasizes not only speed and cost-efficiency but also the structural integrity and longevity of the built environment. Corrugated roofing sheets, particularly those produced by a sophisticated 988 Corrugated roofing sheet forming machine, are instrumental in achieving these objectives. The specific "988" profile is often associated with a net coverage width of approximately 988mm, making it an optimal choice for various large-span construction projects, including factory buildings, agricultural storage sheds, and commercial complexes, due to its efficient coverage and excellent load-bearing characteristics. This profile is engineered to provide superior resistance against environmental stressors such as heavy rainfall, strong winds, and snow loads, crucial for ensuring the safety and durability of structures in diverse climatic zones. The machine’s ability to process a wide array of raw materials, including galvanized steel, Galvalume (Alu-Zinc) steel, and pre-painted galvanized iron (PPGI), expands its versatility and applicability across different architectural requirements and budget considerations. The demand for these machines is steadily increasing, propelled by urbanization, industrial expansion, and the need for resilient infrastructure in developing economies. Furthermore, the global drive towards prefabricated and modular construction methods further boosts the adoption of highly automated roll forming machines, as they enable mass production of standardized components with unparalleled accuracy and consistency. The integration of Industry 4.0 principles, such as IoT sensors for predictive maintenance and real-time performance monitoring, is transforming the operational dynamics of these machines, shifting from reactive repairs to proactive management, thereby significantly enhancing uptime and productivity. These technological advancements ensure that the 988 Corrugated roofing sheet forming machine remains at the forefront of manufacturing innovation, delivering not just roofing sheets but fundamental building blocks for resilient and sustainable development worldwide. The strategic importance of investing in such advanced machinery is increasingly recognized by leading construction firms and steel fabricators who seek to optimize their production processes, reduce operational overheads, and gain a competitive edge in the highly demanding global market.

Understanding the Core Technology: Manufacturing Process of the 988 Corrugated Roofing Sheet Forming Machine

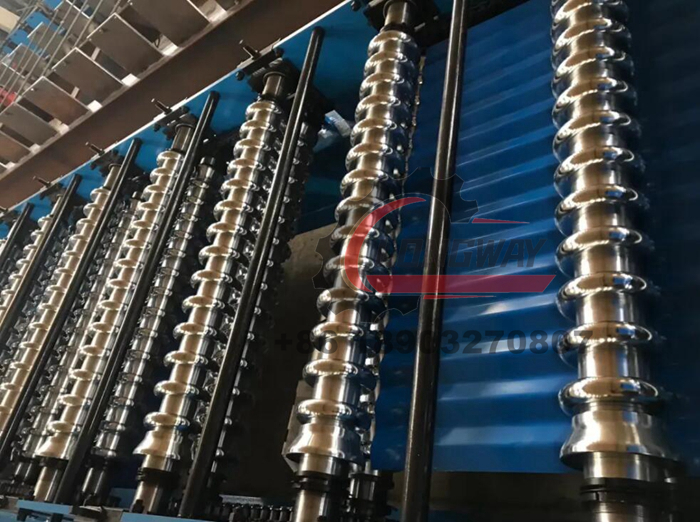

The production of corrugated roofing sheets by the 988 Corrugated roofing sheet forming machine is a sophisticated cold roll forming process, meticulously engineered to transform flat metal coils into robust, geometrically precise corrugated profiles. This multi-stage manufacturing sequence begins with the decoiling of raw material, typically a large coil of galvanized steel, Galvalume steel, or pre-painted galvanized iron (PPGI), which is carefully loaded onto an uncoiler, ensuring smooth and controlled feeding into the subsequent stages. The material quality is paramount; commonly used grades include G300, G550, or equivalent international standards like ASTM A653 or JIS G 3302, selected for their optimal yield strength (e.g., 250-550 MPa) and tensile strength (e.g., 340-690 MPa), which directly influence the finished product's structural integrity and resistance to deformation. Following decoiling, the flat sheet enters the guiding section, where precision guides ensure accurate alignment and prevent lateral movement, critical for maintaining the uniformity of the final profile. The core of the process lies within the roll forming station, which consists of numerous sets of precisely engineered forming rollers. These rollers are typically fabricated from high-grade steel, such as 45# steel or Cr12, often hardened to HRC 58-62 via quenching and tempering, and then precision-machined using advanced CNC processing techniques to achieve extremely tight tolerances. Each set of rollers progressively shapes the metal sheet, gradually bending it into the desired 988 corrugated profile. This gradual formation minimizes internal stresses within the metal, preventing cracking or weakening, a key aspect of cold roll forming technology. The number of forming stations varies depending on the complexity of the profile and desired production speed, but typically ranges from 12 to 18 stations for a 988 Corrugated roofing sheet forming machine, ensuring a smooth transition and precise shaping.

After the roll forming stage, the continuously formed corrugated sheet progresses to the cutting unit. This section typically employs a hydraulic cutting system, chosen for its precision, speed, and clean-cut capability, minimizing burrs and distortion. The cutting length is precisely controlled by a PLC (Programmable Logic Controller) system, which receives input from an encoder to ensure accurate sheet lengths according to pre-programmed specifications. The sophisticated PLC control system, often featuring a user-friendly touch screen interface, provides real-time monitoring of production parameters, diagnostic capabilities, and allows for quick adjustments to production settings, thereby optimizing efficiency and reducing human error. The PLC governs the entire sequence, from decoiling speed to cutting accuracy, ensuring seamless integration of all machine components. Post-cutting, the finished corrugated sheets are automatically stacked onto an output table or conveyor system, ready for packaging, transportation, or direct use. Quality control is integrated throughout the entire process. Before and after roll forming, the material undergoes rigorous inspection to ensure adherence to industry standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material properties, and ANSI (American National Standards Institute) for design specifications. These checks include verification of sheet thickness, coating integrity (e.g., zinc coating thickness or paint adhesion), profile dimensions (pitch, depth, coverage width), and straightness. Non-destructive testing methods may be employed to detect any hidden defects, ensuring that every sheet meets stringent quality benchmarks. The lifespan of a well-maintained 988 Corrugated roofing sheet forming machine is typically 15-20 years, with key components like rollers lasting even longer due to their hardened treatment and precision engineering. This longevity, coupled with low maintenance requirements, makes it a highly economical investment. The applicable industries for these machines are broad, encompassing commercial construction, industrial facilities (such as petrochemical plants, steel mills, and manufacturing units), agricultural buildings, and even civil infrastructure projects like bridge decking or sound barriers. In petrochemical and metallurgy industries, the machine’s ability to process corrosion-resistant materials like pre-painted galvanized steel is highly advantageous, protecting structures from harsh chemical environments and extreme temperatures, thereby extending their service life and ensuring operational safety. For water supply and drainage systems, corrugated sheets are used for covering pump stations or water treatment facilities, where their durability and weather resistance are critical.

Technical Specifications and Performance Metrics of the 988 Corrugated Roofing Sheet Forming Machine

The performance and reliability of a 988 Corrugated roofing sheet forming machine are defined by its technical specifications and meticulously measured performance metrics. These parameters are crucial for prospective buyers and operators to assess the machine's suitability for their specific production needs and ensure optimal return on investment. A typical high-performance 988 machine is designed to handle a wide range of material thicknesses, commonly from 0.3 mm to 0.8 mm, accommodating various structural requirements and material cost considerations. The applicable raw material width generally falls within 1200 mm to 1250 mm, which is then formed into a finished corrugated sheet with an effective width of 988 mm, ensuring efficient material utilization and broad compatibility with standard coil sizes. The main motor power is typically around 5.5 KW to 7.5 KW, providing ample power for smooth and consistent roll forming, even with thicker gauges of steel. The hydraulic station motor, responsible for powering the cutting mechanism, often ranges from 3.0 KW to 4.0 KW, ensuring swift and precise cuts. One of the most critical performance metrics is the forming speed, which can achieve 15 to 25 meters per minute (m/min) in standard operation, translating to significant daily production capacities. For instance, at 20 m/min, a single shift operation (8 hours) can produce approximately 9.6 kilometers of roofing sheets, demonstrating the machine's high output potential. The control system is invariably a state-of-the-art PLC (Programmable Logic Controller) system, such as Siemens, Panasonic, or Mitsubishi, integrated with a user-friendly touch screen display. This advanced control unit allows operators to input precise production parameters, monitor machine status in real-time, troubleshoot issues, and access production data, thereby optimizing workflow and minimizing downtime. The rollers, which are the heart of the forming process, are precision-machined from high-grade 45# steel or Cr12 tool steel, with surfaces polished and hard chrome-plated to ensure durability, minimal friction, and exceptional longevity, often exceeding 10-15 years under regular operation. The robust structure of the machine typically features a main frame constructed from H-beam or channel steel, offering superior stability and vibration resistance during high-speed operations.

Beyond these core specifications, other important technical parameters enhance the overall efficiency and reliability of the 988 Corrugated roofing sheet forming machine. The machine's overall dimensions vary but are typically around 7.5 meters to 8.5 meters in length, 1.5 meters in width, and 1.2 meters in height, with a total weight ranging from 5 to 7 metric tons, depending on the specific configuration and number of forming stations. The number of forming roller stations usually ranges from 14 to 18 groups, each designed for a specific stage of the profile development, ensuring a smooth and gradual forming process that prevents material stress and deformation. The drive system most commonly employs a chain or gear drive, ensuring efficient power transmission and synchronous rotation of the rollers. For optimal performance and safety, the machine operates on a standard industrial voltage (e.g., 380V, 50Hz, 3-phase, or customizable to client's specific power grid). The cutting system, as mentioned, is typically hydraulic, offering clean and precise cuts, with blade material often being Cr12Mov quenched steel for enhanced durability. Accuracy is paramount; cutting length tolerance is usually within ±2mm, and profile accuracy is maintained within ±1mm, critical for seamless sheet integration during installation. The inclusion of an automatic uncoiler with a capacity of 5-10 tons further streamlines the production process, minimizing manual intervention and enabling continuous operation. Advanced models may also include features such as an automatic stacker, which organizes finished sheets into neat bundles, further reducing labor costs and improving operational efficiency. Furthermore, some machines offer optional features like pre-shearing devices, which allow for a cleaner start to the coil, or embossing devices for adding decorative patterns or reinforcing ribs to the sheets. These comprehensive technical specifications underscore the machine's capability to deliver high-quality, high-volume production of corrugated roofing sheets, meeting the stringent demands of modern construction projects across various industries. This detailed insight into the machine's technical prowess allows for informed decision-making and strategic investment.

Typical Technical Parameters for 988 Corrugated Roofing Sheet Forming Machine

| Parameter | Specification | Notes / Industry Standard |

|---|---|---|

| Applicable Material Thickness | 0.3 - 0.8 mm | Galvanized Steel, PPGI, Galvalume (Alu-Zinc) Steel |

| Applicable Material Width | 1200 - 1250 mm | Standard Coil Widths |

| Effective Width of Sheet | 988 mm | Standard profile dimension |

| Forming Speed | 15 - 25 m/min | Adjustable via PLC; depends on material & profile complexity |

| Main Motor Power | 5.5 - 7.5 KW | Ensures consistent roll forming |

| Hydraulic Station Power | 3.0 - 4.0 KW | For precise cutting operations |

| Number of Forming Stations | 14 - 18 Groups | Progressive shaping for stress-free formation |

| Roller Material | 45# Steel / Cr12 | Quenched, Hard Chrome-plated (HRC 58-62) |

| Shaft Diameter | Ø70 - Ø75 mm | Solid steel, ensuring stability |

| Control System | PLC with Touch Screen | Siemens/Panasonic/Mitsubishi options, Delta inverter |

| Cutting Type | Hydraulic Post-cutting | Cr12Mov blades, heat-treated for longevity |

| Cutting Length Tolerance | ±2 mm | High precision for consistent sheets |

| Total Dimensions (L x W x H) | Approx. 7.5 x 1.5 x 1.2 m | Varies with configuration |

| Total Weight | Approx. 5 - 7 Tons | Indicates robust construction |

| Power Supply | 380V, 50Hz, 3-Phase | Customizable to local voltage requirements |

| Uncoiler Capacity | 5 - 10 Tons (Passive/Manual) | Optional hydraulic/automatic uncoiler available |

Diverse Applications and Real-World Scenarios for 988 Corrugated Roofing Sheets

The versatility and robustness of corrugated roofing sheets produced by a 988 Corrugated roofing sheet forming machine render them indispensable across a multitude of industries and construction projects. Their distinctive profile, effective coverage width, and material adaptability make them an ideal choice for diverse applications, ranging from large-scale industrial complexes to intricate agricultural structures. In the industrial sector, these sheets are extensively utilized for roofing and cladding of factories, warehouses, workshops, and processing plants. For instance, in heavy industries such as metallurgy or petrochemicals, where structures are exposed to corrosive atmospheres or high temperatures, the ability to produce sheets from pre-painted galvanized iron (PPGI) or Galvalume steel offers superior corrosion resistance, extending the lifespan of the building envelope and reducing maintenance costs significantly. This anti-corrosive property is crucial for protecting valuable equipment and ensuring operational safety in challenging environments. Beyond the structural benefits, the speed of installation afforded by these lightweight yet strong sheets contributes to rapid project completion, a critical factor in industrial expansion and infrastructure development. The consistent quality and precise dimensions produced by the 988 Corrugated roofing sheet forming machine ensure seamless integration and reduced on-site adjustments, further accelerating construction timelines and minimizing labor expenses.

In the agricultural sector, corrugated roofing sheets are the backbone of various structures, including barns, livestock shelters, greenhouses, and storage facilities for crops and machinery. Their inherent durability, cost-effectiveness, and ease of installation make them a practical solution for agricultural enterprises, providing reliable protection against harsh weather conditions and enabling efficient farm operations. For example, a large-scale poultry farm requires extensive roofing that is both weatherproof and capable of rapid deployment. The efficiency of a 988 Corrugated roofing sheet forming machine allows for the swift production of the required sheets, meeting tight project deadlines. Furthermore, in commercial and retail developments, corrugated sheets are increasingly integrated into modern architectural designs, providing a contemporary aesthetic while retaining their functional advantages. Shopping malls, showrooms, and exhibition centers often leverage these sheets for their extensive coverage and ability to create large, column-free spaces. Even in public infrastructure projects, such as bus stops, train stations, or sports complexes, the sheets offer robust, low-maintenance roofing solutions. Beyond roofing, these sheets find utility in various other structural components, including wall cladding, fencing, and even temporary partitions. Their adaptability in terms of material type (e.g., thermal insulation properties with sandwich panels) and color (via PPGI) further expands their decorative and functional possibilities. The widespread adoption of these sheets across such diverse sectors is a testament to the efficient and reliable output of the advanced 988 Corrugated roofing sheet forming machine, proving its pivotal role in supporting modern infrastructure development and resilient construction practices globally. The capacity to produce sheets that meet international standards for strength and weather resistance is paramount, ensuring that structures built with these materials are safe, durable, and sustainable for decades to come, reducing the need for frequent repairs and replacements, which ultimately contributes to long-term cost savings and environmental responsibility.

Unpacking the Advantages: Why Choose Our 988 Corrugated Roofing Sheet Forming Machine

Choosing the right manufacturing equipment is a strategic decision for any business, and the 988 Corrugated roofing sheet forming machine offers a compelling suite of advantages that translate directly into operational efficiency, cost savings, and superior product quality. Firstly, the precision and consistency of the output are unparalleled. Thanks to advanced CNC machining of rollers and a sophisticated PLC control system, each corrugated sheet produced adheres to exact dimensional specifications (e.g., pitch accuracy within ±0.5mm, profile height within ±0.3mm). This high level of accuracy ensures that every sheet fits perfectly during installation, significantly reducing on-site fabrication time, minimizing material waste, and enhancing the overall structural integrity of the roof. Traditional methods or less precise machinery often lead to variations, resulting in rework, increased labor costs, and compromised structural performance. Secondly, the machine boasts impressive production efficiency. With forming speeds reaching up to 25 meters per minute, it can fulfill large-volume orders rapidly, dramatically shortening lead times for major construction projects. This high throughput is crucial for manufacturers aiming to meet demanding market schedules and capitalize on emerging opportunities. The automated decoiling and stacking systems further optimize this efficiency by minimizing manual intervention, reducing the risk of human error, and creating a continuous production flow. This translates to lower operational costs per unit produced, directly boosting profitability. The energy-saving aspect is also a significant advantage; modern 988 Corrugated roofing sheet forming machine models incorporate energy-efficient motors and optimized hydraulic systems, reducing power consumption during operation compared to older, less efficient models. This reduction in energy footprint not grueling only lowers utility bills but also aligns with global sustainability initiatives, offering an attractive proposition for environmentally conscious businesses.

Durability and reliability are core tenets of our 988 Corrugated roofing sheet forming machine. Constructed from robust high-strength steel frames and featuring hardened, chrome-plated rollers, the machine is designed for continuous, heavy-duty operation with minimal wear and tear. The expected operational lifespan of 15-20 years for the main frame and even longer for the rollers (with proper maintenance) ensures a long-term return on investment and reduced capital expenditure over time. This longevity is supported by stringent material selection and manufacturing processes, adhering to international standards for mechanical strength and fatigue resistance. Furthermore, the machine is highly adaptable to various material types and thicknesses, allowing manufacturers to diversify their product offerings without needing multiple specialized machines. It can seamlessly process galvanized steel, pre-painted galvanized iron (PPGI), and Galvalume steel, each with different coatings and properties suitable for various applications and environmental conditions. This flexibility empowers businesses to cater to a broader client base and respond quickly to market shifts. The integrated safety features, including emergency stop buttons, protective guards, and automated fault detection via the PLC system, ensure a safe working environment for operators, minimizing the risk of accidents and compliance issues. Our comprehensive after-sales support, including installation assistance, operator training, technical troubleshooting, and readily available spare parts, ensures maximum uptime and sustained productivity. For instance, our typical delivery cycle ranges from 30 to 45 working days, followed by a 12-24 month warranty period, demonstrating our commitment to client satisfaction and product reliability. This blend of high precision, efficiency, durability, versatility, and dedicated support positions our 988 Corrugated roofing sheet forming machine as a superior choice for businesses seeking to enhance their manufacturing capabilities and achieve a competitive edge in the global construction materials market. These combined benefits underscore the strategic value of this advanced roll forming solution.

Navigating the Market: Manufacturer Comparison & Custom Solutions

When investing in a 988 Corrugated roofing sheet forming machine, prospective buyers face a market populated by numerous manufacturers, each offering varying levels of quality, technology, and support. A thorough comparison is essential to ensure a sound investment that aligns with long-term business objectives. Key factors to consider during this evaluation include the manufacturer's reputation, service longevity, technological advancements, quality certifications, and after-sales support. Reputable manufacturers, often those with over 15-20 years of experience in the roll forming industry, typically provide machines built to higher standards, utilizing superior materials and more refined engineering processes. For instance, a manufacturer with ISO 9001 certification indicates adherence to international quality management systems, assuring consistent product quality and reliable manufacturing processes. Furthermore, evaluating the type of PLC system used (e.g., Siemens, Mitsubishi vs. generic brands), the quality of hydraulic components (e.g., Rexroth vs. unbranded units), and the materials used for rollers (e.g., Cr12Mov hardened steel vs. lesser alloys) provides insights into the machine's expected performance and longevity. While some manufacturers might offer seemingly lower initial prices, these often come with compromises in component quality, lower production speeds, less precise output, and inadequate post-sale support, leading to higher total cost of ownership (TCO) due to frequent breakdowns and maintenance issues. Conversely, investing in a machine from a trusted, technologically advanced manufacturer may involve a higher upfront cost but promises superior reliability, higher uptime, lower operational expenses, and a significantly longer operational life, culminating in a far greater return on investment. It's also vital to examine the warranty period and the scope of technical support, including remote diagnostics, on-site service, and spare parts availability, which are crucial for maintaining continuous production.

Beyond standard offerings, the capability to provide custom solutions is a distinguishing factor for leading 988 Corrugated roofing sheet forming machine manufacturers. While the 988 profile is standardized, clients often have specific requirements related to material handling, production speed, automation level, or integration with existing production lines. For example, a client may require a machine capable of processing exceptionally thin or thick materials (e.g., 0.25mm or 1.0mm), or a system with an integrated auto-stacking and wrapping unit for fully automated packaging. Some projects might necessitate specialized cutting solutions for non-standard lengths or complex patterns. A truly client-centric manufacturer offers robust customization capabilities, including:

- Material Adaptability: Modifying roller designs or material feeding systems to handle specific alloys, coated steels, or even non-metallic composites.

- Speed Optimization: Engineering higher-speed options for mass production environments or lower-speed, higher-precision configurations for specialized applications.

- Automation Integration: Incorporating advanced automation features such as automatic coil loading, robotic stacking, inline quality inspection systems (e.g., laser-based profile verification), and integration with enterprise resource planning (ERP) systems for seamless data flow.

- Profile Customization: While 988 is standard, slight variations in rib height, pitch, or minor aesthetic alterations can be engineered to meet unique architectural or structural demands.

- Safety and Compliance: Customizing safety features to meet specific regional industrial safety standards (e.g., OSHA, CE directives).

- Power and Environmental Considerations: Adapting the machine's power requirements to specific electrical grids and incorporating features for reduced noise or dust emissions.

Manufacturer Comparison Snapshot (Illustrative)

| Feature/Criteria | Leading Tier 1 Manufacturer (e.g., LW Roll Forming Machine) | Typical Tier 2 Manufacturer | Budget/Entry-level Manufacturer |

|---|---|---|---|

| Experience & Reputation | 20+ years, Global Presence, Strong R&D | 10-15 years, Regional Focus, Standard Models | <10 years, Local Market, Basic Offerings |

| Quality Certifications | ISO 9001, CE, SGS Audited | Basic ISO, some CE | Limited or No Certifications |

| PLC System Brand | Siemens / Panasonic / Mitsubishi | Delta / Inovance | Generic / Unbranded |

| Roller Material & Treatment | Cr12Mov, Quenched (HRC 58-62), Precision CNC | 45# Steel, Chrome Plated, Standard Machining | Ordinary Steel, Minimal Treatment |

| Main Frame Construction | High-strength H-Beam/Channel Steel, Welded & Heat-treated | Standard Channel Steel, Welded | Lighter Steel, Basic Welding |

| Forming Speed (Average) | 20-25 m/min (Consistent) | 15-20 m/min (Variable) | 10-15 m/min (Less Stable) |

| Output Precision | <±1mm profile, <±2mm length | ±2-3mm profile, ±5mm length | >±3mm profile, >±5mm length |

| Customization Capability | Extensive, Tailored Solutions | Limited, Minor Modifications | None, Standard Products Only |

| After-Sales Support | Global On-site Support, Remote Diagnostics, Fast Spares | Regional Support, Delayed Spares | Minimal/No Support, Difficult Spares |

| Warranty Period | 12-24 Months | 12 Months | 6 Months or Less |

Client Success Stories and Implementation Insights

The true measure of a 988 Corrugated roofing sheet forming machine’s value lies in its real-world application and the success it brings to clients. Our long-standing commitment to quality and innovation has allowed us to partner with numerous industry leaders globally, transforming their production capabilities and boosting their market competitiveness. One notable case involves a prominent steel fabrication company in Southeast Asia that was struggling with inconsistent sheet profiles and high material waste from their older, less precise machinery. After integrating our customized 988 Corrugated roofing sheet forming machine, equipped with advanced servo-driven feeding and an upgraded PLC system for enhanced precision, they reported a dramatic reduction in scrap rates by approximately 15% and an increase in production output by 30% within the first six months. This led to significant cost savings in raw materials and labor, allowing them to take on larger, more demanding projects with confidence. Their client satisfaction improved due to the superior quality of the corrugated sheets, resulting in repeat business and new contracts in commercial and industrial roofing sectors. Another success story comes from a major construction conglomerate in the Middle East, which required a high-speed, robust solution for a series of large-scale infrastructure projects, including pre-engineered buildings for oil & gas facilities and logistical hubs. Our machine’s ability to operate continuously for extended periods, coupled with its robust construction suitable for harsh desert environments, proved invaluable. The average daily production capacity surpassed their previous equipment by 40%, enabling them to complete the roofing phase of multiple projects ahead of schedule, translating into millions in accelerated revenue and avoided penalties. This partnership underscored the importance of machine durability and consistent performance in high-pressure, high-volume production environments.

Beyond sheer volume, the implementation of our 988 Corrugated roofing sheet forming machine has also facilitated innovation for our clients. A specialized architectural firm in Europe, aiming for sustainable building practices, utilized our machine to process thinner gauge, high-strength recycled steel for their eco-friendly building designs. The machine's precise control over the forming process ensured that even these delicate materials were accurately shaped without tearing or deforming, a challenge that older machines could not overcome. This enabled the firm to achieve their sustainability goals while maintaining structural integrity and aesthetic appeal, setting a new benchmark in green construction. Our technical team provided extensive training to their operators and maintenance staff, ensuring seamless integration and optimal utilization of the machine's advanced features. This comprehensive support is a cornerstone of our service, guaranteeing that clients not only acquire superior machinery but also gain the expertise required to maximize its potential. We often conduct site visits post-installation to gather feedback and fine-tune machine parameters, ensuring long-term operational excellence. These real-world applications demonstrate that investing in a high-quality 988 Corrugated roofing sheet forming machine is not merely an equipment purchase, but a strategic partnership that delivers tangible benefits, fosters growth, and strengthens market position. The consistent positive feedback from our global clientele, spanning diverse industries and geographical regions, is a testament to the reliability, efficiency, and superior performance of our machines, making them a preferred choice for businesses committed to excellence in metal forming. Our dedication to continuous improvement and client success ensures that our machines remain at the forefront of the industry, delivering impactful solutions for complex construction demands.

Ensuring Trust: Quality Assurance, Certifications, and Support

Trust is the bedrock of B2B relationships, particularly when dealing with capital equipment like the 988 Corrugated roofing sheet forming machine. Our commitment to trustworthiness is demonstrated through rigorous quality assurance protocols, adherence to international certifications, and comprehensive customer support. Every machine undergoes a multi-stage quality control process, starting from the procurement of raw materials. We source high-grade steel for the main frame and rollers from certified suppliers, ensuring that all components meet stringent metallurgical standards. During manufacturing, each major assembly, including the roll forming section, cutting unit, and electrical control cabinet, is individually tested for precision, alignment, and functionality. For instance, rollers are subjected to hardness tests (e.g., Rockwell hardness test for HRC 58-62) and dimensional checks with high-precision instruments to ensure their conformity to design specifications. The entire machine undergoes a comprehensive pre-delivery run-test, typically for 24-48 hours, operating at full capacity to simulate real-world production conditions. During this test, parameters such as forming speed, cutting accuracy, power consumption, and noise levels are meticulously monitored and recorded. Only after passing all these rigorous tests and quality checks, verified by our internal quality assurance team and often by third-party inspectors like SGS or Bureau Veritas, is the machine deemed ready for shipment. Our manufacturing facility adheres to ISO 9001:2015 quality management system standards, ensuring that all processes from design to delivery are systematically controlled and continuously improved. Furthermore, our machines are designed to meet relevant international safety and performance standards, including CE Marking for the European market and compliance with specific national electrical codes, providing assurance of safety and reliability to our global clientele. These certifications are not merely badges but represent our unwavering dedication to engineering excellence and regulatory compliance, ensuring that every 988 Corrugated roofing sheet forming machine we deliver is a testament to superior craftsmanship and reliable performance, contributing to a lower total cost of ownership and maximizing the client's operational uptime.

Our commitment to customer success extends far beyond the point of sale. We understand that investing in a 988 Corrugated roofing sheet forming machine is a significant decision, and comprehensive support is crucial for maximizing its operational efficiency and lifespan. We provide detailed delivery schedule information, typically outlining a lead time of 30-45 working days from order confirmation to ex-works readiness, with clear communication regarding shipping and logistics. Upon delivery, our experienced engineers are available for on-site installation and commissioning services, ensuring that the machine is set up correctly and integrated seamlessly into your existing production line. This includes calibration, testing, and initial run-throughs to verify optimal performance. We provide extensive operator training, covering machine operation, routine maintenance procedures, basic troubleshooting, and safety protocols, empowering your staff to operate the machine efficiently and safely. Our robust warranty commitment typically ranges from 12 to 24 months for major components, covering any manufacturing defects. Beyond the warranty period, we offer continuous technical support, accessible via phone, email, and remote diagnostics, allowing us to quickly identify and resolve potential issues. Our global network of service partners and readily available spare parts inventory ensure minimal downtime in the event of a component failure. We pride ourselves on rapid response times, understanding that every hour of downtime translates to lost productivity for our clients. For example, critical spare parts can often be shipped within 24-48 hours. This holistic approach to quality assurance and customer support builds lasting partnerships, reinforcing our reputation as a trusted provider of high-performance metal forming machinery and ensuring that your investment in a 988 Corrugated roofing sheet forming machine yields sustained productivity and profitability for years to come. Our dedication to proactive maintenance advice and regular system updates further ensures that your machine performs at its peak, aligning with the latest industry best practices and technological advancements.

Frequently Asked Questions (FAQ) about the 988 Corrugated Roofing Sheet Forming Machine

-

Q1: What types of materials can the 988 Corrugated roofing sheet forming machine process?

A1: Our 988 Corrugated roofing sheet forming machine is highly versatile and capable of processing a wide range of metal coil materials commonly used in roofing. These include galvanized steel (GI), pre-painted galvanized iron (PPGI), and Galvalume (Alu-Zinc) steel. The machine can handle material thicknesses typically ranging from 0.3 mm to 0.8 mm, allowing for flexibility in manufacturing sheets for various load-bearing requirements and budget considerations. The choice of material impacts the final product's corrosion resistance, aesthetic appeal, and structural properties, all of which our machine is optimized to process efficiently and precisely, ensuring high-quality output regardless of the specific metal alloy or coating used.

-

Q2: What is the typical production speed of this machine?

A2: The standard forming speed for our 988 Corrugated roofing sheet forming machine ranges from 15 to 25 meters per minute (m/min). This speed is dependent on factors such as the material thickness, the complexity of the profile (though the 988 profile is standardized, material properties can influence speed), and the desired cutting length. For optimal performance, the machine's PLC control system allows for precise speed adjustments, ensuring efficient operation while maintaining peak product quality. At its maximum speed, the machine can produce a substantial volume of corrugated sheets daily, making it ideal for high-demand industrial and commercial projects, significantly reducing production lead times and enhancing overall operational throughput for our clients.

-

Q3: What kind of after-sales support and warranty do you offer?

A3: We provide comprehensive after-sales support to ensure the long-term optimal performance of your 988 Corrugated roofing sheet forming machine. This includes on-site installation and commissioning services by our experienced engineers, thorough operator training covering machine operation, maintenance, and safety, and continuous technical assistance via phone, email, or remote diagnostics. We offer a standard warranty period of 12 to 24 months for major components, covering any manufacturing defects. Beyond the warranty, we ensure the availability of genuine spare parts and offer maintenance contracts to minimize downtime and maximize the machine's lifespan. Our aim is to build a lasting partnership, providing reliable support throughout the machine's operational life, ensuring your investment remains productive and profitable.

-

Q4: Can the machine be customized for specific project requirements?

A4: Absolutely. While our 988 Corrugated roofing sheet forming machine is a highly standardized and efficient product, we understand that unique project requirements may arise. We offer extensive customization options to tailor the machine to your specific needs. This can include adjustments for handling different material widths or thicknesses beyond the standard range, integrating advanced automation features like automatic coil loading, robotic stacking, or inline quality inspection systems, and incorporating specific power requirements for your region. We can also modify the control system for specialized reporting or connectivity with your ERP systems. Our engineering team works closely with clients to develop bespoke solutions that optimize machine performance for their unique operational environment and production goals, ensuring maximum efficiency and compatibility.

-

Q5: What are the typical delivery and installation timelines?

A5: The typical delivery schedule for a standard 988 Corrugated roofing sheet forming machine ranges from 30 to 45 working days from the confirmation of your order and receipt of the initial deposit. This timeframe accounts for manufacturing, rigorous quality control testing, and preparation for shipment. Once the machine arrives at your facility, our professional engineers can be dispatched for on-site installation and commissioning, which typically takes an additional 5-7 working days, depending on the site conditions and complexity. This includes setting up the machine, connecting utilities, calibration, and initial test runs. Comprehensive training for your operating and maintenance staff is also conducted during this period, ensuring your team is fully equipped to run the machine efficiently from day one, minimizing any potential delays in your production schedule.

Conclusion and Future Outlook for Corrugated Roofing Technology

The 988 Corrugated roofing sheet forming machine represents a pinnacle of engineering excellence in the cold roll forming industry, offering a powerful blend of precision, efficiency, and durability crucial for modern construction demands. Its capability to consistently produce high-quality, perfectly profiled corrugated sheets from a variety of materials underpins its indispensability across industrial, commercial, and agricultural sectors. As detailed, the meticulous manufacturing process, from material selection and CNC-machined rollers to advanced PLC control systems and hydraulic cutting, ensures that every output sheet meets stringent international standards for strength, dimension, and longevity. The technical advantages, including high production speeds, superior material utilization, and robust construction, translate directly into significant operational cost savings and increased profitability for businesses investing in this technology. Furthermore, the commitment to rigorous quality assurance, comprehensive certifications like ISO 9001 and CE, and a robust after-sales support system, including timely delivery, on-site installation, extensive training, and reliable warranty, solidifies the trust and confidence that clients place in our machinery. This holistic approach ensures not only a high-performance machine but also a long-term partnership aimed at maximizing client success and minimizing operational disruptions. The ability to offer tailored solutions further enhances its value, allowing businesses to optimize their production lines for unique material specifications, automation requirements, or integration with existing manufacturing ecosystems, thereby reinforcing its position as a strategic asset in competitive markets.

Looking ahead, the future of corrugated roofing sheet technology, and consequently the evolution of the 988 Corrugated roofing sheet forming machine, is poised for continued innovation driven by global trends in sustainable construction, smart manufacturing, and material science. We anticipate further advancements in machine intelligence, integrating predictive maintenance algorithms powered by artificial intelligence and machine learning to forecast potential component failures before they occur, drastically reducing unscheduled downtime. The adoption of advanced robotics for material handling and finished product stacking will become even more prevalent, enhancing automation levels and reducing manual labor requirements, thereby improving workplace safety and efficiency. Research into new, lighter, and stronger composite materials, as well as bio-based or recycled metal alloys, will necessitate more adaptable roll forming machines capable of processing these novel substrates without compromising structural integrity or production speed. Furthermore, the increasing demand for energy-efficient buildings will likely push for integration of features that enable the production of corrugated sheets with enhanced thermal insulation properties or photovoltaic integration directly on the sheet, contributing to net-zero energy buildings. The focus will also shift towards more modular and portable roll forming solutions, allowing on-site fabrication for remote projects, reducing transportation costs and logistics complexities. These future developments underscore the dynamic nature of the industry and our continuous commitment to research and development, ensuring that our 988 Corrugated roofing sheet forming machine remains at the cutting edge, empowering our clients to meet the evolving challenges and opportunities of the global construction landscape. The strategic investment in such advanced and future-proof technology is paramount for businesses seeking sustained growth and leadership in the metal building materials sector.

Industry References and Further Reading

1. Cold Roll Forming Technology & Applications. Journal of Manufacturing Processes, Volume 35, October 2018, Pages 251-267. https://www.sciencedirect.com/science/article/pii/S152661251830154X

2. Advances in Steel Construction: From Research to Practice. Proceedings of the International Conference on Steel and Composite Structures (ICOSCS), various years. (Specific conference proceedings may vary, typically found in engineering libraries or databases like IStructE or ASCE).

3. Modern Trends in Roll Forming Systems. Metal Form Journal, Vol. 15, Issue 2, 2021. (Specific journal and issue may vary, representing common industry publications).

4. The Future of Smart Manufacturing in Metal Forming. Automation World, 2023. https://www.automationworld.com/smart-manufacturing/article/22894235/the-future-of-smart-manufacturing-in-metal-forming

5. ASTM A653/A653M - Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. https://www.astm.org/a0653_a0653m-23.html (Official ASTM website)

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025