Precision Deck 950 Composite Panel Machine | High-Speed Production

Introduction to Advanced Decking Roll Forming Technology

In the dynamic realm of modern construction, efficiency, structural integrity, and cost-effectiveness are paramount. Collaborative deck systems, also known as composite floor decking, represent a cornerstone for rapid and robust structural solutions. At the forefront of manufacturing these essential components is the Maquina para PLACA/PANEL COLABORANTE Deck 950. This specialized roll forming machine is engineered to produce high-quality, precision-profiled steel deck panels that serve as permanent formwork and positive reinforcement in concrete floor slabs, significantly accelerating construction timelines and enhancing load-bearing capabilities.

Designed for industrial-scale production, the Maquina para PLACA/PANEL COLABORANTE Deck 950 embodies advanced mechatronics, offering unparalleled accuracy and repeatability. Its robust construction and sophisticated control systems ensure consistent output, meeting stringent international building codes and project specifications. This article delves into the critical aspects of this technology, exploring its operational mechanics, market relevance, and the significant advantages it confers upon B2B enterprises in the construction materials sector.

Industry Trends in Composite Decking Manufacturing

The global construction industry is experiencing a profound shift towards prefabrication and modular construction, driven by demands for faster project delivery, reduced on-site labor, and enhanced safety. This trend directly fuels the demand for high-performance composite decking. Key trends influencing the sector include:

- Automation and Digitalization: The integration of PLC (Programmable Logic Controller) systems, HMI (Human-Machine Interface) touch screens, and even IoT capabilities is becoming standard in roll forming machines. This enables precise control, real-time monitoring, and predictive maintenance, optimizing production efficiency and minimizing downtime.

- Sustainability and Material Efficiency: A growing emphasis on sustainable building practices means manufacturers are seeking machines that can process high-strength, lighter-gauge steel more efficiently, reducing material waste and energy consumption. The ability to produce optimized panel profiles further contributes to structural efficiency.

- Increased Demand for Long Span and Fire-Rated Solutions: Modern architectural designs often call for larger, open spaces, necessitating decking solutions that can span greater distances without excessive propping. Furthermore, stringent fire safety regulations drive demand for composite decking systems designed to meet specific fire resistance ratings, often achieved through specialized profiles and concrete pour depths.

- Customization and Profile Versatility: While standard deck profiles remain essential, there's a growing need for machines capable of producing a variety of profiles or offering quick changeover capabilities to meet diverse project requirements, from commercial high-rises to industrial complexes.

These trends highlight the critical role of advanced machinery like the Maquina para PLACA/PANEL COLABORANTE Deck 950 in enabling manufacturers to stay competitive and responsive to market needs.

Detailed Process Flow: Manufacturing with the Maquina Deck 950

The production of high-quality composite deck panels using the Maquina para PLACA/PANEL COLABORANTE Deck 950 involves a sophisticated, multi-stage cold roll forming process. Understanding this process is key to appreciating the machine's capabilities and the quality of its output.

1. Materials and Machine Construction

The machine itself is constructed from high-grade industrial materials designed for durability and precision. Structural components typically utilize welded steel frames (e.g., Q235, Q345 structural steel) for rigidity, often stress-relieved after welding to prevent deformation. Critical components like roll dies are crafted from high-alloy tool steel (e.g., Cr12, Cr12MoV), heat-treated to HRC58-62 for exceptional wear resistance and precision profiling. Shafts are commonly made from 45# high-strength steel, often quenched and tempered. Bearings, electrical components, and hydraulic systems are sourced from reputable international brands to ensure reliability and performance. Manufacturing processes for the machine's components include CNC machining for roll precision, surface grinding, and precise assembly, often adhering to ISO 9001 quality management standards.

2. Roll Forming Process Stages

- Coil Loading and Decoiling: The process begins with loading a large coil of galvanized or pre-painted steel sheet (typically G300-G550 grade, 0.7mm to 1.6mm thickness) onto a hydraulic or manual decoiler. The decoiler accurately unwinds the steel strip, feeding it into the main roll forming line. Tensioning systems ensure smooth and consistent material flow, crucial for profile accuracy.

- Feeding and Guiding: The steel strip passes through a pre-shearing and guiding unit. This ensures the strip is perfectly aligned before entering the roll stands, preventing mis-profiling and material waste. Precision guides, often adjustable, adapt to varying material widths.

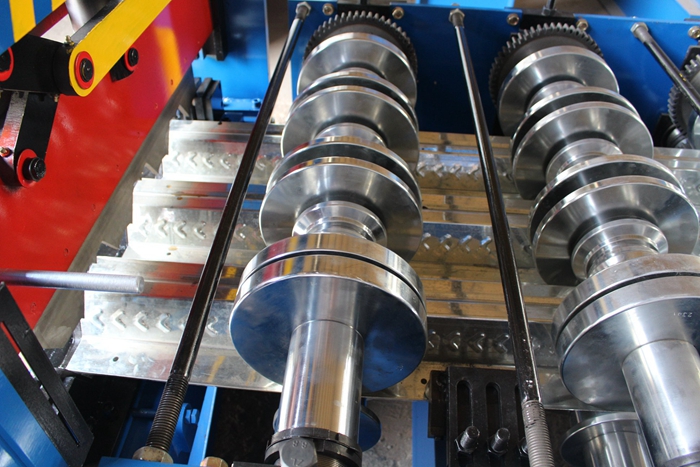

- Roll Forming Section:

This is the core of the operation. The strip sequentially passes through a series of precision-engineered roll stands (typically 18-24 stations for complex deck profiles). Each pair of rolls incrementally shapes the metal, gradually forming the distinct ribs, indentations, and interlocking features of the Deck 950 profile. The design of these rolls is critical, ensuring the steel's yield strength is carefully managed to prevent tearing or over-stressing while achieving the desired dimensional accuracy. The rolling speed is precisely controlled by a variable frequency drive (VFD) system.

The precision roll forming process, showing sequential shaping of the steel panel. - Post-Forming Cutting: After the desired profile is fully formed, the continuous panel moves to a hydraulic or flying shear cutting unit. This unit, synchronized with the roll former's speed via encoder feedback and PLC control, precisely cuts the panel to the specified length. The cutting process is clean and burr-free, maintaining the integrity of the panel edges.

- Output Table and Stacking: The cut panels are then discharged onto an output table, where they are typically stacked manually or automatically, ready for packaging and transport. Some advanced systems include automatic stacking and bundling mechanisms.

This meticulous process, overseen by a centralized PLC control system, ensures that each panel produced by the Maquina para PLACA/PANEL COLABORANTE Deck 950 meets the exact dimensional and structural requirements for optimal performance in composite slab construction.

Technical Specifications and Parameters

The performance of the Maquina para PLACA/PANEL COLABORANTE Deck 950 is defined by its robust technical specifications, which guarantee high throughput, precision, and durability.

Product Specification Table: Maquina para PLACA/PANEL COLABORANTE Deck 950

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.7 mm - 1.6 mm (Galvanized Steel, PPGI) |

| Effective Width of Panel | 950 mm |

| Feeding Width of Coil | 1250 mm (standard) |

| Forming Speed | Up to 15-20 m/min (adjustable) |

| Number of Roll Stations | 18-24 (profile dependent) |

| Main Motor Power | 11 kW - 18.5 kW (depending on configuration) |

| Hydraulic System Power | 5.5 kW |

| Control System | PLC Control (Siemens/Delta options) with HMI Touch Screen |

| Cutting System | Hydraulic Post-Cutting |

| Machine Dimensions (approx.) | Length 9500mm x Width 1600mm x Height 1500mm |

| Total Weight (approx.) | 8-12 Tons |

| Voltage | 380V, 50Hz, 3 Phase (customizable) |

Application Scenarios and Industry Impact

The composite deck panels produced by the Maquina para PLACA/PANEL COLABORANTE Deck 950 are indispensable in a multitude of construction applications, offering superior structural performance and construction speed.

- High-Rise Commercial Buildings: Decking provides a fast and efficient floor construction method, reducing reliance on traditional formwork and allowing subsequent trades to commence earlier. Its high strength-to-weight ratio is crucial for multi-story structures.

- Industrial Facilities and Warehouses: For structures requiring large clear spans and heavy floor loads, composite decking is ideal. It contributes to robust floor systems capable of supporting machinery, storage, and dynamic loads.

- Parking Structures: The inherent durability and monolithic behavior of composite slabs make them suitable for parking garages, where resistance to vehicular traffic, moisture, and de-icing salts is paramount.

- Infrastructure Projects: Bridges and elevated walkways can benefit from the rapid installation and structural efficiency of composite decking, particularly in areas where minimal disruption is essential.

- Residential and Mixed-Use Developments: While often associated with larger projects, composite decking is increasingly utilized in residential buildings for its sound attenuation properties, fire resistance, and overall structural integrity.

Customer feedback consistently highlights the reliability of machines delivering consistent panel quality, critical for preventing on-site delays and ensuring compliance with structural engineering designs. A recent client in a large-scale industrial park project reported a 25% reduction in concrete slab pouring time due to the precise and robust panels produced by their new decking machine, directly translating to earlier project completion and significant cost savings.

Technical Advantages and Competitive Edge

Investing in the Maquina para PLACA/PANEL COLABORANTE Deck 950 offers distinct technical advantages that translate into significant operational benefits for manufacturers.

- High Precision and Profile Consistency: Advanced roll tooling design, often optimized using FEA (Finite Element Analysis) software, ensures minimal material stress and exceptional dimensional accuracy across long production runs. This consistency is vital for structural integrity and ease of installation on-site.

- Robust Construction for Longevity: The machine's frame, made from high-strength steel, and its hardened, precision-ground roll dies guarantee a prolonged service life, even under continuous heavy-duty operation. This minimizes maintenance costs and maximizes uptime.

- Intelligent Control Systems: Siemens or Delta PLC systems with intuitive HMI interfaces provide operators with comprehensive control over speed, length, batch quantity, and diagnostics. This intelligent automation reduces human error, improves safety, and allows for rapid adjustments.

- Efficient Material Utilization: The precision cutting system, typically a hydraulic post-cut shear, minimizes waste. Optimized roll designs can also allow for thinner gauge materials to achieve required performance, leading to material cost savings.

- Energy Efficiency: Modern motor and drive systems, including VFDs, optimize power consumption, reducing operational energy costs. The efficiency of the cold roll forming process itself is also inherently more energy-efficient than hot rolling.

- Safety Features: Comprehensive safety measures, including emergency stops, protective covers, and overload protection for motors and hydraulic systems, are integrated to ensure operator safety and compliance with industrial standards like CE.

Vendor Comparison and Authoritativeness

When evaluating roll forming equipment, discerning buyers look beyond basic specifications to assess vendor credibility and product longevity. Our company's commitment to quality is underpinned by over 15 years of industry experience, serving clients across diverse sectors.

Vendor Comparison: Key Differentiators

| Feature/Aspect | Our Maquina Deck 950 | Typical Competitor (Entry-Level) | High-End European Brand |

|---|---|---|---|

| Roll Material & Hardness | Cr12/Cr12MoV, HRC58-62, precise CNC machining | 45# steel, often less hardening, basic machining | SKD11/D2, HRC60+, advanced machining & coatings |

| Control System | Siemens/Delta PLC, HMI touch screen, encoder feedback | Basic PLC, push-button interface, less robust sensors | Advanced PLC, remote diagnostics, optional IoT integration |

| Forming Speed (Max) | Up to 20 m/min | 8-12 m/min | 25-40 m/min |

| Precision Tolerance | +/- 1.0mm (length), +/- 0.5mm (width/profile) | +/- 2.0mm (length), +/- 1.0mm (width/profile) | +/- 0.5mm (length), +/- 0.2mm (width/profile) |

| Certifications | CE, ISO 9001 | Often none or basic local | CE, TUV, relevant national standards |

| Post-Sales Support | Installation, training, 24/7 online support, parts supply | Limited, often reliant on distributors | Global network, comprehensive service contracts |

Our position provides an optimal balance of advanced technology, robust construction, and competitive pricing, making the Maquina para PLACA/PANEL COLABORANTE Deck 950 an attractive investment for businesses seeking reliable performance without the premium cost of ultra high-end solutions. We pride ourselves on transparent operations, adherence to international testing standards like ASTM A653 for steel materials and EN 1994 for composite structures, and a consistent track record with satisfied clients globally.

Customized Solutions

Recognizing that every B2B client has unique operational needs and project specifications, we offer extensive customization options for the Maquina para PLACA/PANEL COLABORANTE Deck 950.

- Profile Design Adaptation: While the Deck 950 is a standard, popular profile, we can engineer and manufacture roll sets for alternative deck profiles, including trapezoidal or dovetail, to meet specific structural or architectural requirements.

- Material Handling Systems: Customization extends to decoiler capacity (e.g., 5-ton to 15-ton), adding coil cars for automated loading, and integrating automatic stackers or packaging systems to streamline the entire production line.

- Speed and Production Volume: Depending on desired throughput, motor power, gearbox configurations, and control algorithms can be optimized for higher production speeds, ensuring the machine aligns with projected demand.

- Integrated Punching/Embossing: For specialized applications requiring pre-punched holes or embossed logos, additional inline punching or embossing units can be seamlessly integrated into the roll forming line.

- Electrical and Safety Standards: Voltage, frequency, and specific safety protocols (e.g., OSHA, region-specific electrical codes) can be adapted to comply with the destination country's regulations.

Application Case Studies

Our advanced roll forming machines have been deployed in various challenging projects, demonstrating their reliability and the efficiency of their output.

Case Study 1: Major Logistics Hub Expansion, Southeast Asia

A leading logistics provider in Southeast Asia required a rapid expansion of their regional distribution center, necessitating over 150,000 square meters of new floor space. They procured a specialized Maquina para PLACA/PANEL COLABORANTE Deck 950 system to produce the required composite floor decking in-house. The machine's consistent output of 950mm wide panels, combined with its high operational speed, allowed the client to meet an aggressive construction schedule. The use of precisely formed decking minimized on-site adjustments, leading to a 10% reduction in overall structural labor costs and completion of the slab work 3 weeks ahead of schedule. The robust panels provided excellent structural support for the heavy loads inherent in logistics operations.

Case Study 2: Multi-Story Office Complex, Middle East

In a prestigious multi-story office development in the Middle East, a construction firm utilized our Deck 950 machine to produce fire-rated composite floor panels. The requirement was for high-strength decking capable of forming a composite slab system with a 2-hour fire resistance rating. The precision of the machine ensured that the profile geometry was strictly maintained, crucial for the composite action and fire performance. The client lauded the machine’s reliability under continuous operation in a demanding climate and the minimal material wastage, which contributed to achieving their LEED certification goals. Our technical support team provided on-site training and commissioning, ensuring seamless integration into their production facility.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with our B2B partners is foundational. We provide comprehensive support throughout the entire lifecycle of the Maquina para PLACA/PANEL COLABORANTE Deck 950.

Frequently Asked Questions (FAQ)

- Q: What types of steel can the machine process?

A: The machine is primarily designed for galvanized steel, pre-painted galvanized steel (PPGI), and cold-rolled steel with yield strengths typically ranging from G300 to G550, and thicknesses from 0.7mm to 1.6mm. - Q: What is the typical lead time for delivery?

A: Standard configurations typically have a lead time of 45-60 working days from order confirmation. Customized machines may require 75-90 working days due to design and manufacturing complexities. - Q: Is on-site installation and training provided?

A: Yes, we provide optional on-site installation, commissioning, and comprehensive operator training by our experienced technicians to ensure smooth integration and optimal performance. - Q: How do I get spare parts?

A: We maintain a robust inventory of critical spare parts. Orders can be placed directly through our customer support, with expedited shipping options available to minimize downtime.

Lead Time and Fulfillment

Our efficient production and supply chain management ensure timely delivery. Each machine undergoes rigorous quality control checks and pre-shipment testing before dispatch. We work with trusted logistics partners for secure global shipping, providing detailed tracking and customs documentation support.

Warranty Commitments

We offer a standard 12-month warranty on all mechanical components and 6 months on electrical components, starting from the date of commissioning or 18 months from shipment, whichever comes first. This warranty covers manufacturing defects and component failures under normal operating conditions. Extended warranty packages are available upon request.

Customer Support

Our commitment extends beyond delivery. We provide 24/7 online technical support via phone, email, and video conferencing. Our dedicated service team is ready to assist with troubleshooting, operational guidance, and maintenance queries, ensuring your production line remains operational and efficient. Regular maintenance schedules and preventative service packages can also be arranged.

Conclusion

The Maquina para PLACA/PANEL COLABORANTE Deck 950 represents a vital investment for any enterprise engaged in modern construction and material manufacturing. Its integration of advanced technology, robust engineering, and comprehensive support positions it as a market leader in producing high-quality composite floor decking. By enabling efficient, precise, and reliable production, this machine empowers businesses to meet the evolving demands of the construction industry, ensuring structural integrity, accelerated project timelines, and superior economic returns. As the global construction landscape continues to prioritize innovation and efficiency, the strategic acquisition of such advanced roll forming capabilities becomes not just an option, but a necessity for competitive advantage.

References

- American Society for Testing and Materials (ASTM). ASTM A653/A653M, Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process.

- European Committee for Standardization (CEN). EN 1994 (Eurocode 4): Design of composite steel and concrete structures.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- Wang, J., & Guo, W. (2018). Advanced Cold Roll Forming Technology for Steel Structures. Journal of Structural Engineering, 144(7).

- Smith, R. (2020). The Future of Prefabricated Construction. Construction Today Magazine, 15(2).

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025