High-Precision Steel C U Purlin Roll Forming Machine

Industry Trends and Market Demand for Purlin Roll Forming

The global construction industry continues to expand, driven by urbanization, infrastructure development, and industrial growth. Within this dynamic landscape, the demand for efficient and robust structural components, particularly purlins, remains consistently high. Purlins, essential in roof and wall construction, provide critical support for roofing sheets, insulating materials, and cladding. The efficiency and quality of purlin production directly impact project timelines and structural integrity.

Traditional methods of purlin manufacturing often involve labor-intensive processes that lack consistency and speed. However, the advent of advanced roll forming technology has revolutionized this sector. Modern Steel C U purlin Roll Forming Machine systems offer unparalleled precision, speed, and versatility, enabling manufacturers to produce high-quality C, U, Z, and other custom profiles with minimal material waste. This technological shift addresses the escalating demand for lightweight, high-strength steel structures across various sectors, from commercial buildings and industrial warehouses to agricultural facilities and solar panel installations.

Key trends influencing the adoption of these machines include the push for sustainable construction practices, which favors steel over heavier, more resource-intensive materials, and the need for rapid deployment in large-scale projects. Automation and integration of smart manufacturing principles are also paramount, leading to machines that offer sophisticated control systems, automated tooling changes, and real-time monitoring capabilities. These innovations not only enhance productivity but also contribute significantly to reducing operational costs and improving worker safety, solidifying the role of advanced roll forming solutions in modern construction.

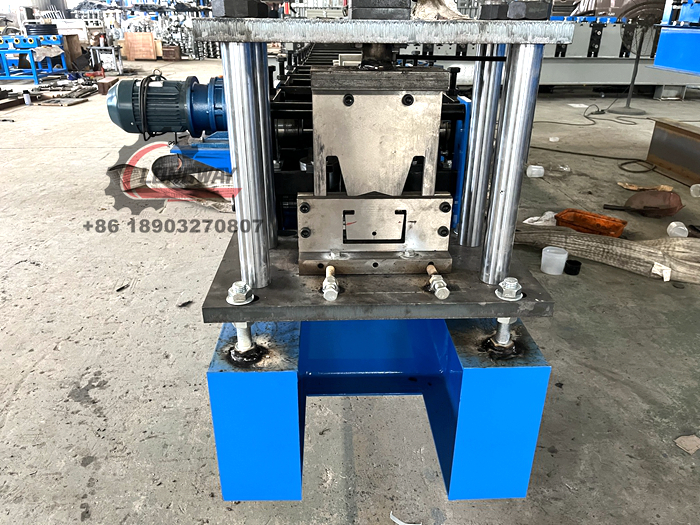

Detailed Process Flow of the Steel C U Purlin Roll Forming Machine

The manufacturing process of a Steel C U purlin Roll Forming Machine is a testament to precision engineering, combining robust material selection with advanced fabrication techniques to ensure longevity, reliability, and superior performance. Below is a detailed breakdown of the machine's construction and operational flow.

Machine Manufacturing Process and Materials:

- Frame Fabrication: The foundational structure of the machine, typically a heavy-duty welded steel frame, is constructed from high-grade structural steel (e.g., Q235, Q345). Components are laser-cut for precision, welded using advanced MIG/MAG processes, and then stress-relieved to prevent warping and ensure long-term stability. This forms the backbone, supporting all subsequent modules.

- Roller Production: Rollers are the heart of the forming process. They are meticulously designed using advanced CAD/CAM software to achieve the desired purlin profile. Materials typically include high-chromium tool steel (e.g., GCr15, SKD11) or 45# steel with subsequent hardening treatments. Rollers undergo precision CNC machining, followed by heat treatment (quenching and tempering to HRC58-62) to maximize wear resistance and surface hardness. Finally, they are hard chrome plated for enhanced durability and reduced friction.

- Shaft Manufacturing: The shafts that support and drive the rollers are made from high-strength alloy steel (e.g., 40Cr, 45# steel). They are precision-machined, ground, and often subjected to induction hardening to withstand significant torsional and bending stresses during operation.

- Cutting System Components: The cutting die, often hydraulic or pneumatic, is fabricated from high-wear-resistant tool steel (e.g., Cr12Mov). These components undergo precision wire-cut EDM (Electrical Discharge Machining) and fine grinding to ensure clean, burr-free cuts. Heat treatment to HRC60-62 is critical for extending the die's service life.

- Hydraulic/Pneumatic Systems: High-quality pumps, cylinders, valves, and tubing from reputable global suppliers are integrated to provide precise and reliable power for cutting, punching, and sometimes auto-changing systems. Components are selected for their durability and leak-free performance under continuous operation.

- Electrical and Control Systems: Incorporating PLCs (Programmable Logic Controllers) from brands like Siemens, Panasonic, or Mitsubishi, alongside HMI (Human-Machine Interface) touchscreens, variable frequency drives (VFDs), and precision encoders. Wiring adheres to international electrical standards (e.g., IEC, NEMA) for safety and reliability.

- Assembly and Calibration: All machined and treated components are meticulously assembled. Critical alignments (e.g., roller parallelism, cutting accuracy) are calibrated using laser alignment tools and precision gauges.

- Surface Treatment: After fabrication and assembly, the machine frame typically undergoes shot blasting to clean the surface, followed by a multi-layer industrial paint coating (e.g., epoxy primer, polyurethane topcoat) for enhanced corrosion resistance and aesthetic appeal.

Operational Process Flow of Purlin Production:

- Decoiling: A coil of galvanized or black steel strip, typically ranging from 1.5mm to 3.0mm thickness (depending on purlin specifications), is loaded onto an automatic or manual decoiler. The decoiler feeds the material smoothly into the machine.

- Feeding and Guiding: The steel strip passes through a feeding and guiding unit that ensures proper alignment and tension, preventing material deviation before entering the forming section.

- Punching (Optional): For purlins requiring pre-punched holes for bolted connections, the strip enters a hydraulic or pneumatic punching station. This unit precisely punches holes according to programmed specifications, ensuring accuracy and consistency.

- Roll Forming: The core of the operation. The steel strip progressively passes through a series of roller stations. Each station incrementally bends the metal to form the desired C or U profile. The number of stations (typically 12-20) depends on the complexity of the profile and material thickness. Precision-engineered rollers apply controlled pressure, shaping the material without stretching or tearing.

- Straightening: After forming, a straightening mechanism ensures the purlin is perfectly straight, compensating for any minor distortions induced during the forming process.

- Cutting: Once the purlin reaches the programmed length, a hydraulic post-cutting device severs it from the continuous strip. The cutting operation is typically synchronized with the line speed to minimize material waste and maintain accuracy.

- Output Table/Stacking: The finished purlins are then conveyed to an output table or an automated stacking system, ready for packaging, storage, or immediate use.

Testing Standards and Service Life:

Our Steel C U purlin Roll Forming Machine undergoes rigorous quality control at every stage. Key components and the assembled machine are tested against international standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and CE marking for European safety compliance. Critical mechanical parts are tested for hardness (Rockwell, Brinell), tensile strength, and fatigue resistance. Electrical systems comply with ANSI/UL standards where applicable.

With proper maintenance and adherence to operational guidelines, the typical service life of our machines is designed to exceed 15-20 years, with critical components like rollers and cutting dies having defined lifespans based on throughput, offering millions of linear meters of production before replacement is needed.

Target Industries and Application Scenario Advantages:

This versatile machinery serves a broad spectrum of industries, including:

- Building & Construction: Industrial workshops, warehouses, exhibition centers, gymnasiums, residential buildings.

- Infrastructure: Airports, railway stations, bus terminals, bridge supports.

- Agricultural: Greenhouses, livestock shelters, cold storage facilities.

- Energy Sector: Solar panel mounting structures, power plant ancillary buildings.

- Logistics: Distribution centers, cargo hubs.

In these scenarios, the machine's advantages are evident:

- Energy Saving: Optimized motor efficiency (e.g., IE3 rated motors) and advanced hydraulic systems reduce power consumption per meter of purlin produced. Precision forming minimizes material waste, further contributing to resource efficiency.

- Corrosion Resistance: By processing pre-galvanized steel coils, the machine produces purlins with inherent corrosion resistance, crucial for structures in harsh environments like coastal areas or industrial zones where exposure to chemicals is common. This extends the service life of the entire building structure.

- High Strength-to-Weight Ratio: The precise forming capabilities allow for the production of purlins with optimized cross-sections, providing superior structural integrity with less material, reducing overall building weight and foundation requirements.

- Rapid Deployment: The high production speed and accuracy of the machine enable quicker manufacturing cycles, significantly accelerating construction project timelines.

Technical Specifications and Performance Parameters

Understanding the detailed technical specifications of a Steel C U purlin Roll Forming Machine is crucial for evaluating its suitability for specific production requirements. Our machines are engineered for robust performance and high precision, designed to meet the demanding standards of modern manufacturing.

Core Product Specifications:

| Parameter | Specification / Value | Unit / Description |

|---|---|---|

| Material Thickness Range | 1.5 - 3.0 | mm (Galvanized / Cold-rolled steel, G350-G550 yield strength) |

| Material Width (Max.) | 500 | mm |

| Forming Speed (Adjustable) | 10 - 25 | m/min (Purlin without punching) |

| Number of Forming Stations | 16 - 20 | Stations (optimized for C/U profiles) |

| Main Motor Power | 11 - 18.5 | kW (Siemens/ABB IE3 efficiency class) |

| Hydraulic Station Power | 7.5 - 11 | kW (for cutting and punching) |

| Shaft Diameter | ø75 - ø90 | mm (Solid 40Cr steel, precision ground) |

| Roller Material | GCr15/SKD11 | Hard chrome plated, HRC 58-62 hardness |

| Cutting Type | Hydraulic Post-Cutting | Non-stop shear, precise length control (encoder) |

| Control System | PLC (Siemens/Panasonic) | Touch screen HMI, multi-language support |

| Machine Dimensions (Approx.) | 9000 × 1500 × 1600 | mm (Length × Width × Height) |

| Total Weight (Approx.) | 7 - 10 | Tons (depending on configuration) |

These parameters highlight the capability of our Steel C U purlin Roll Forming Machine to produce a wide range of C and U purlin sizes with exceptional accuracy and efficiency. The integration of high-quality components and advanced control systems ensures minimal downtime and consistent product quality.

Application Scenarios and Technical Advantages

The versatility and efficiency of the Steel C U purlin Roll Forming Machine enable its application across numerous critical construction and industrial environments. Its technical advantages are designed to deliver tangible benefits, enhancing project efficiency, structural integrity, and long-term cost-effectiveness.

Typical Application Scenarios:

- Industrial Buildings: Large-span factory workshops, manufacturing plants, and logistics warehouses rely heavily on C and U purlins for robust roof and wall framing. The ability to produce varying purlin dimensions and punching patterns on-demand makes these machines indispensable for bespoke industrial projects.

- Commercial Structures: Shopping malls, office complexes, and convention centers often utilize cold-formed steel purlins for their aesthetic flexibility and structural efficiency, particularly in supporting diverse roofing and cladding materials.

- Agricultural Facilities: Modern barns, greenhouses, and storage sheds benefit from the light-weight yet strong purlins, offering cost-effective and durable solutions that can withstand environmental stresses.

- Renewable Energy Installations: Solar farms and wind power facilities use purlins for mounting structures, requiring precise, durable components that can be rapidly produced and installed in remote or challenging locations.

- Modular Construction: The precision and consistency of roll-formed purlins are perfectly suited for prefabricated and modular building systems, where components are manufactured off-site and assembled rapidly on-site.

Technical Advantages:

- High Production Efficiency: With adjustable forming speeds typically ranging from 10-25 meters per minute, the machine significantly boosts output, allowing for rapid fulfillment of large orders and reduced project lead times. Automated operation minimizes manual intervention, reducing labor costs.

- Versatile Profile Production: Our machines are designed with quick changeover capabilities, allowing for the production of various C and U purlin sizes and even Z profiles, often within minutes. This flexibility caters to diverse project specifications without requiring multiple dedicated machines.

- Superior Product Quality & Accuracy: Precision-engineered rollers and advanced PLC control systems ensure tight dimensional tolerances (e.g., length accuracy of ±1mm) and consistent profile geometry. This adherence to specifications is critical for structural integrity and ease of assembly on-site.

- Reduced Material Waste: Optimized cutting and punching systems, combined with precise length control, minimize scrap material. This not only lowers operational costs but also aligns with sustainable manufacturing practices.

- Robust Construction & Durability: Built with heavy-duty steel frames, hardened tool steel rollers (GCr15), and reliable hydraulic and electrical components, the machine ensures a long service life and stable operation even under continuous heavy-duty use. This minimizes maintenance needs and maximizes uptime.

- User-Friendly Operation: The intuitive Human-Machine Interface (HMI) with touchscreen controls allows operators to easily set parameters, monitor production, and diagnose issues. Integrated safety features comply with international standards, enhancing workplace safety.

- Integrated Punching Capabilities: Many models incorporate pre-punching units, enabling the creation of custom hole patterns for bolted connections. This eliminates the need for post-production punching, saving time and ensuring precise alignment.

Vendor Comparison and Customized Solutions

Selecting the right Steel C U purlin Roll Forming Machine vendor is a strategic decision that impacts long-term operational efficiency, product quality, and return on investment. While numerous manufacturers exist, differentiating factors in machine technology, service, and customization are paramount.

Key Considerations for Vendor Comparison:

- Technological Innovation: Leading vendors invest in R&D to integrate features like intelligent control systems (Industry 4.0 readiness), quick-change tooling, and energy-efficient components. Evaluate the PLC brand (e.g., Siemens, Panasonic), HMI capabilities, and data logging functions.

- Component Quality: Scrutinize the origin and quality of critical components: main motor (e.g., Siemens, ABB), hydraulic pump (e.g., Bosch Rexroth, Vickers), bearings (e.g., SKF, FAG), and electrical components (e.g., Schneider, Eaton). High-quality components ensure reliability and extended service life.

- After-Sales Support & Warranty: A strong after-sales network, including readily available spare parts, technical support, and on-site service, is crucial. Compare warranty periods for different machine parts and the responsiveness of technical assistance.

- Customization Capabilities: Not all projects fit standard machine configurations. A reputable vendor should offer tailored solutions, from custom profile designs to integrated punching/notching, embossing, or automated stacking systems.

- Certifications & Reputation: Look for international certifications (CE, ISO, SGS) and testimonials from established clients. A vendor's years of experience and specialization in roll forming technology also indicate reliability. Our company adheres to ISO 9001 and holds various product-specific certifications, alongside a track record of serving over 200 clients globally for more than 15 years.

Customized Solutions: Tailoring Your Roll Forming Machine

Recognizing that every client's needs are unique, we offer extensive customization options for our Steel C U purlin Roll Forming Machine to perfectly align with specific operational requirements and production goals.

- Profile Design & Flexibility: We can design and manufacture rollers for custom C, U, or even Z purlin profiles, accommodating unique web heights, flange widths, and lip dimensions. Multi-profile machines (e.g., C/Z interchangeability) are also available, often with automated tooling changes.

- Material Handling Systems: Custom decoilers (hydraulic, double-head, heavy-duty for larger coils), automated feeding tables, and integrated stacking/packaging systems can be tailored to optimize material flow and reduce labor.

- Punching & Notching Integration: Specific punching patterns, hole sizes, and notching requirements can be integrated into the machine's design. This includes pre-punching units with multiple hydraulic cylinders for complex patterns or flying punch systems for high-speed applications.

- Control System Enhancements: Options include advanced HMI with production data logging, remote diagnostics capabilities, integration with existing MES/ERP systems, and specialized safety features (e.g., light curtains, emergency stop protocols tailored to specific plant layouts).

- Production Speed & Capacity: Machines can be engineered for higher line speeds or to accommodate thicker/wider material, impacting motor power, roller design, and cutting system specifications.

- Environmental & Safety Adaptations: Custom dust extraction systems, noise reduction enclosures, and specific electrical standards (e.g., voltage, frequency, wiring according to local codes) can be implemented.

Our engineering team collaborates closely with clients from conceptualization to commissioning, leveraging extensive industry experience to deliver solutions that precisely match operational demands and future growth projections.

Application Case Studies

The proven performance of our Steel C U purlin Roll Forming Machine is best illustrated through real-world applications. These case studies highlight how our technology delivers tangible benefits and meets diverse industrial demands.

Case Study 1: Large-Scale Industrial Warehouse in Southeast Asia

Client Profile: A leading construction material supplier in Vietnam, tasked with providing structural components for a 200,000 sq. meter logistics warehouse.

Challenge: The client required high-volume production of C-purlins (C150, C200, C250) and U-channels (U100, U150) in various lengths, with specific punching patterns, all while maintaining strict deadlines and quality standards for galvanized steel (G550, 2.0mm thickness). Manual processes were too slow and inconsistent.

Solution: We supplied a fully automated, high-speed Steel C U purlin Roll Forming Machine with an integrated flying hydraulic punching system and an automatic size changeover feature. The machine was equipped with a heavy-duty hydraulic decoiler to handle large steel coils, minimizing material reloading downtime.

Results:

- Production increased by 180%, enabling the client to meet aggressive project timelines.

- Material waste reduced by 7% due to precise cutting and punching.

- Labor costs decreased by 40% through automation.

- Achieved consistent purlin quality with length accuracy within ±1mm and excellent profile stability, leading to smoother on-site assembly.

- The system ran for 16 hours daily with minimal downtime, reporting an uptime exceeding 98%.

Case Study 2: Agricultural Greenhouse Project in the Middle East

Client Profile: An agricultural development company in Saudi Arabia, building a series of advanced climate-controlled greenhouses.

Challenge: The project required custom U-channels (U80) from thin-gauge galvanized steel (1.5mm) for structural supports, along with specific pre-punched holes for fastening greenhouse cladding. The corrosive desert environment necessitated highly durable, precisely formed components.

Solution: We provided a specialized Steel C U purlin Roll Forming Machine tailored for lighter gauge materials, featuring corrosion-resistant rollers and a highly accurate pre-punching system capable of multiple hole configurations. The machine's control system allowed for easy programming of varying lengths and hole patterns.

Results:

- Successfully produced over 50,000 linear meters of custom U-channels within the project timeframe.

- Punching accuracy maintained within 0.5mm, ensuring perfect alignment with pre-drilled cladding.

- The machine's robust design handled challenging operating temperatures, ensuring continuous production.

- Client reported a 25% saving in installation time due to the consistent quality and precise fit of the purlins.

FAQ, Lead Time, Warranty, and Customer Support

Frequently Asked Questions (FAQ)

-

Q: What types of steel can this machine process?

A: Our Steel C U purlin Roll Forming Machine is designed to process various types of steel coils, including galvanized steel, cold-rolled steel, pre-painted steel, and sometimes stainless steel (depending on customization), with thicknesses typically ranging from 1.5mm to 3.0mm and yield strengths from G350 to G550. -

Q: Can the machine produce multiple purlin sizes?

A: Yes, standard machines can produce a range of C and U profiles by manually adjusting roller positions. For rapid, tool-less changes between different sizes or even C/Z profiles, we offer automated quick-change systems, allowing adjustments within minutes via the HMI. -

Q: What is the power requirement for the machine?

A: The total installed power typically ranges from 20 kW to 30 kW, depending on the specific configuration (e.g., main motor, hydraulic pump, optional punching units). We can adapt the electrical system to various global voltages and frequencies (e.g., 380V/50Hz, 480V/60Hz). -

Q: What kind of maintenance does the machine require?

A: Regular maintenance includes checking hydraulic fluid levels, lubricating moving parts, inspecting electrical connections, and cleaning rollers and cutting dies. A detailed maintenance schedule is provided in the operator's manual, designed to maximize machine lifespan and performance. -

Q: Is training provided for operators?

A: Yes, comprehensive training is provided during installation and commissioning, either on-site at the client's facility or at our factory. This covers operation, basic troubleshooting, and routine maintenance to ensure operators are fully proficient.

Lead Time and Fulfillment

Our typical lead time for a standard Steel C U purlin Roll Forming Machine is 60-90 business days from the confirmation of order and receipt of the initial deposit. This duration allows for precision manufacturing, thorough quality control, and rigorous pre-shipment testing. Customized machines with specific features or complex tooling may require a longer lead time, which will be clearly communicated during the quotation phase. We pride ourselves on transparent communication and timely delivery, with regular updates provided throughout the manufacturing process.

Warranty Commitments

We stand behind the quality and reliability of our machines. Each Steel C U purlin Roll Forming Machine comes with a standard 12-month warranty from the date of commissioning or 15 months from the date of shipment, whichever comes first. This warranty covers manufacturing defects in materials and workmanship for all major mechanical, electrical, and hydraulic components. Wear parts (e.g., cutting blades, certain bearings) are covered for a limited period or specific usage. Extended warranty options are available upon request.

Customer Support Information

Our commitment to customer satisfaction extends beyond the sale. We offer comprehensive after-sales support to ensure your roll forming machine operates at peak performance throughout its lifespan:

- Technical Assistance: Available via phone, email, or video conference. Our skilled technicians are ready to diagnose and assist with operational queries and troubleshooting.

- On-Site Support: For complex issues, installation, or comprehensive training, our engineers are available for on-site visits globally.

- Spare Parts: A comprehensive inventory of genuine spare parts is maintained for prompt dispatch, minimizing potential downtime. Critical components can be expedited for urgent requirements.

- Remote Diagnostics: Machines equipped with advanced PLC systems often support remote access, allowing our engineers to diagnose and resolve software-related issues directly.

- Documentation: Each machine is supplied with a complete set of user manuals, electrical diagrams, hydraulic schematics, and spare parts lists.

For immediate support, please contact our dedicated service team at service@lwrollformingmachine.com or call us at +86-123-4567-890 during business hours.

References

- European Committee for Standardization. EN 10162: Cold rolled steel sections - Technical delivery conditions - Tolerances on dimensions and shape. Brussels: CEN, 2003.

- International Organization for Standardization. ISO 9001: Quality management systems — Requirements. Geneva: ISO, 2015.

- Pfeiffer, J. Roll Forming Handbook: Precision and Performance. Boca Raton: CRC Press, 2006.

- Cold-Formed Steel Engineers Institute. AISI S100-16: North American Specification for the Design of Cold-Formed Steel Structural Members. Washington D.C.: CFSEI, 2016.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025