Africa 686 IBR Roof Sheet Machine - High-Eff.,Customizable,Durable

The Africa 686 IBR Roof Sheet Making Machine is a cutting-edge solution designed to meet the growing demand for durable and cost-effective roofing materials in Africa and beyond. Developed by Cangzhou Longway International Trade Co., Ltd., this machine combines advanced engineering with user-friendly features to deliver high-quality IBR (Inverted Box Rib) roof sheets efficiently. Whether for residential, industrial, or commercial projects, the Africa 686 model stands out for its versatility, precision, and economic performance.

Product Overview

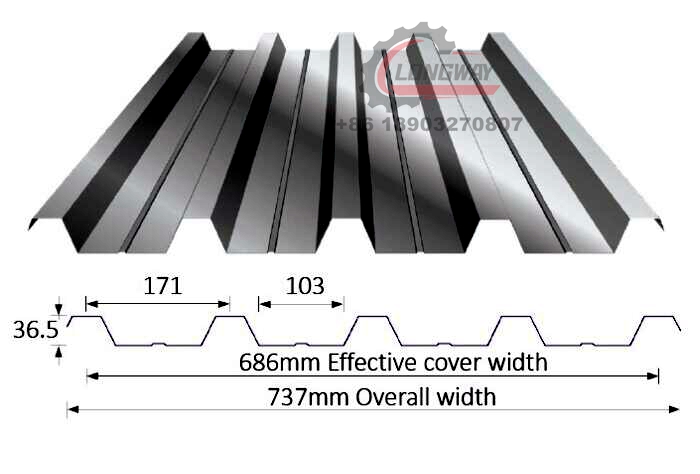

The Africa 686 IBR Roof Sheet Making Machine is engineered to produce IBR sheets with a thickness range of 0.3 to 0.8 mm. Its robust design and customizable capabilities make it ideal for a wide range of applications. The machine’s ability to handle standard profiles and custom designs ensures that it caters to diverse customer needs. With a focus on efficiency, the Africa 686 model is equipped to handle high-volume production while maintaining precision and quality.

The machine’s trapezoidal rib design enhances material efficiency, offering a high strength-to-weight ratio. This feature not only reduces material costs but also ensures the final product is lightweight yet durable. The clean lines and versatile installation options (vertical, diagonal, or horizontal) make the IBR sheets a popular choice for modern construction projects.

Key Features

- Customizable Design: The machine supports both standard profiles and custom designs, allowing manufacturers to tailor products to specific project requirements.

- High Production Capacity: With a forming speed of 15–20 meters per minute, the Africa 686 ensures efficient and rapid production.

- Durable Construction: The machine’s 350 mm H-beam structure and 18 mm welded steel middle support plate ensure stability and longevity.

- Advanced Control System: Equipped with a PLC Delta control system and a touch screen interface, the machine offers precise and user-friendly operation.

- Material Efficiency: The trapezoidal rib design maximizes material usage, reducing waste and costs.

The machine’s Africa 686 IBR Roof Sheet Making Machine also features a separate rolling design, which minimizes internal stress in the sheets, resulting in high precision and a flawless finish. The hydraulic pillar-type cutting system ensures accurate length control, while the chain drive mechanism (1-inch double chain) provides reliable power transmission.

Advantages

The Africa 686 IBR Roof Sheet Making Machine offers several advantages that set it apart from competitors:

- Cost-Effectiveness: The machine’s high production capacity and material efficiency reduce overall costs, making it an economical choice for manufacturers.

- Flexibility: The ability to produce both standard and custom profiles allows businesses to adapt to market demands quickly.

- Durability: Constructed with high-grade 45# forged steel rollers and a robust frame, the machine is built to withstand heavy-duty use.

- User-Friendly Operation: The touch screen interface and PLC control system simplify operation, even for less experienced users.

- Wide Application: Suitable for residential, industrial, and commercial projects, the machine’s versatility ensures a broad market reach.

Additionally, the machine’s design minimizes maintenance requirements, ensuring long-term reliability. The inclusion of anti-corrosive measures, such as spraying anti-oxidation oil on rollers and packaging with isolation films, further enhances its durability during transportation and storage.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Thickness Range | 0.3–0.8 mm |

| Raw Material | PPGI, PPGL, GI |

| Power Requirement | 380V/3PH/50Hz (Customizable) |

| Main Motor Power | 4+4 kW |

| Cutter Power | 4 kW |

| Forming Speed | 15–20 m/min |

| Machine Frame | 350 mm H-Beam Structure |

| Forming Shafts | 75 mm Solid Shaft with Heat Treatment |

| Roller Material | High-Grade 45# Forged Steel |

| Forming Stations | 14–18 Rows |

| Transmission Type | Chain Drive (1-inch Double Chain) |

| Cutting Type | Hydraulic Pillar Type and Length-Set Cutting |

| Control System | PLC Delta and Inverter Delta |

| Dimensions (Approx.) | 7.5 m × 1.5 m × 1.2 m |

| Total Weight (Approx.) | 4.6 T |

Application Scenarios

The Africa 686 IBR Roof Sheet Making Machine is designed to cater to a wide range of applications, making it a versatile choice for various industries. Its high strength-to-weight ratio and customizable design make it ideal for:

- Residential Projects: The machine produces lightweight yet durable IBR sheets suitable for homes, apartments, and community buildings.

- Industrial Facilities: Its robust construction and high production capacity make it perfect for manufacturing roofing materials for warehouses, factories, and storage facilities.

- Commercial Buildings: The machine’s ability to create aesthetically pleasing and functional roofing solutions makes it a top choice for offices, shopping centers, and other commercial spaces.

- Infrastructure Development: The Africa 686 model is also used in constructing roads, bridges, and other infrastructure projects that require durable and cost-effective roofing solutions.

Company Background

Cangzhou Longway International Trade Co., Ltd. is a leading manufacturer and supplier of roll forming machines, specializing in the production of metal roofing and wall panel systems. With years of experience in the industry, the company has established a strong reputation for delivering high-quality, reliable, and innovative machinery solutions. Their commitment to customer satisfaction is evident in their comprehensive services, including OEM/ODM customization, global shipping, and after-sales support.

The company serves a diverse clientele across Africa, Asia, and other regions, with notable clients in countries such as Chile, Iran, the Philippines, and South Africa. Their focus on quality, efficiency, and customer-centric solutions has made them a trusted partner for businesses seeking to enhance their production capabilities.

Conclusion

The Africa 686 IBR Roof Sheet Making Machine is a testament to the advancements in manufacturing technology, offering a blend of efficiency, durability, and customization. Its ability to produce high-quality IBR sheets at a competitive cost makes it an ideal choice for businesses operating in the construction and manufacturing sectors. With a strong company background and a commitment to innovation, Cangzhou Longway International Trade Co., Ltd. continues to lead the way in providing cutting-edge solutions for global markets.

References

1. National Institute of Standards and Technology (NIST). (n.d.). About NIST. Retrieved from https://www.nist.gov/.

2. NIST Standards and Measurements. (n.d.). Retrieved from https://www.nist.gov/standards-and-measurements.

3. NIST Publications. (n.d.). Retrieved from https://www.nist.gov/publications.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025