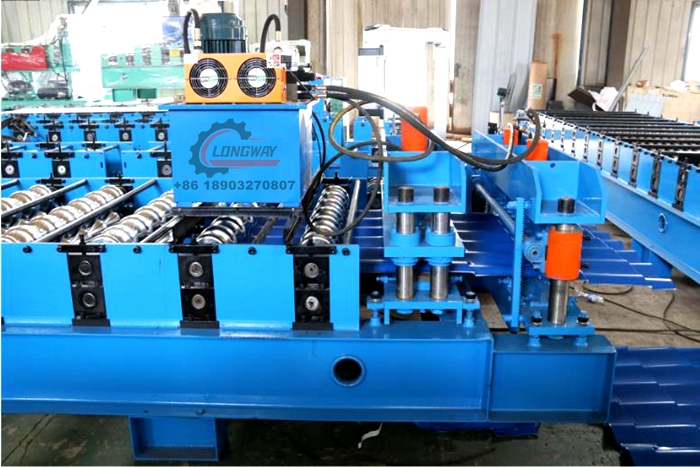

Euro 1100 Metal Roof Tile Making Machine | High-Speed, PLC

Euro 1100 Metal Roof Tile Making Machine: fast, neat tiles with real-world reliability

If you’re watching the roofing game, you’ve noticed the shift: color-coated steel tiles replacing old corrugated sheets on warehouses, schools, even modular homes. To be honest, the sweet spot right now is stable output with tight tolerances, not just headline speed. That’s where the Euro 1100 Metal Roof Tile Making Machine has been quietly winning projects—helped by its 2-year free warranty and straightforward support from Cangzhou (yep, SHIBAWUXING Village, Bo Town, Hebei Province—an area that lives and breathes roll forming).

What’s trending (and why it matters)

Roofing buyers ask for AZ-coated (aluzinc) coils, higher yield strengths (G300–G550), and tile profiles that look “European” but install quickly. In practice, that means controlled step-pressing, gentle forming for pre-painted layers, and a machine that handles 0.3–0.6 mm thickness without scratching. Many customers say they’d rather accept 4 m/min steady than 8 m/min with rework. Makes sense.

Core specifications (field-proven)

| Model / Profile | Euro 1100 tile; effective cover ≈1100 mm (real-world ±2 mm) |

| Input coil width | ≈1220–1250 mm |

| Material | PPGI/PPGL, GI, GL; 235–550 MPa yield |

| Thickness range | 0.3–0.6 mm (best finish at 0.35–0.5 mm) |

| Speed | ≈3–6 m/min (step-press mode); tolerance ±1.0 mm |

| Stations / shafts | 16–20 stations; Ø70 mm shafts, 45# steel, hard-chrome |

| Drive / power | AC motor ≈7.5 kW + hydraulic unit ≈5.5 kW |

| Control | PLC (Siemens/Delta), HMI length/step/qty presets |

| Decoiler | 5T manual standard; 5–7T hydraulic optional |

| Noise / power |

Process flow, materials, and QA

Flow: decoiling → guiding/leveling → roll forming → step pressing → hydraulic cutting → run-out table/stacker. Methods emphasize anti-scratch guiding and synchronized step press (tile pitch ≈300–400 mm). The Euro 1100 Metal Roof Tile Making Machine is tuned for pre-painted coils; tooling hardness HRC ≈58–62 keeps the profile crisp.

- Testing: straightness ≤1.5 mm/10 m; edge wave control on coated coils; sample tiles measured every 50 pcs.

- Standards & safety: CE (Machinery Directive 2006/42/EC), low-voltage/EMC; factory QC under ISO 9001 systems.

- Expected service life: rollers 8–10 years; machine frame 15+ years with lubrication and coolant checks (real-world use may vary).

Where it’s used (and what buyers say)

Applications: industrial roofs, education buildings, supermarkets, quick-build housing, coastal projects (PPGL with AZ150 helps). A reseller in Eastern Europe told me their install teams cut waste by ≈3% thanks to tighter length tolerance; a Kenyan EPC liked the conservative speed—“fewer rejects on thin PPGI,” they said. Surprisingly, many prefer the manual decoiler for maintenance simplicity.

Customization options

- Tile pitch and embossing depth; step height variants for “Euro” aesthetics.

- Hydraulic decoiler with coil car; auto stacker; oiling unit for delicate coatings.

- Flying shear vs. stop-to-press (I guess most choose stop-to-press for finish quality).

- Brandable HMI language packs; remote diagnostics.

Vendor snapshot: what you actually get

| Vendor/Feature | LW (Cangzhou) | Imported EU brand | Budget no-name |

|---|---|---|---|

| Warranty | 2 years (parts/labor guidance) | 1–2 years | 6–12 months (varies) |

| Delivery time | ≈30–45 days | ≈60–90 days | Uncertain |

| Certification pack | CE dossier + test logs | CE/UKCA | Sparse or none |

| After-sales | Remote PLC support; quick spares | Strong, but pricier | Inconsistent |

Small but useful test data

- Coating integrity: no visible micro-cracks at 2T bend (common PPGI spec; verify per your coil grade).

- Cut length tolerance: ±1.0 mm @ 3–5 m/min on 0.45 mm PPGL, ambient 20–28°C.

- Salt spray (coil spec driven): AZ150 often passes 500 h per ASTM B117; your mileage depends on supplier.

Bottom line: if you need an all-rounder tile line with sane speed, clean finish, and parts you can actually source locally, the Euro 1100 Metal Roof Tile Making Machine is tough to ignore.

- ISO 9001:2015 Quality Management Systems – https://www.iso.org/standard/62085.html

- EU Machinery Directive 2006/42/EC – https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32006L0042

- ASTM B117 Salt Spray Test – https://www.astm.org/b0117-19.html

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025