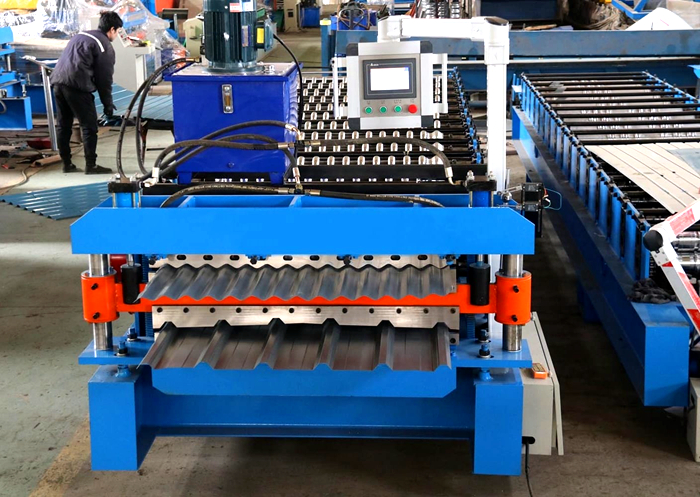

Double Layer Roll Forming Machine For Roofing Sheet - 2-in-1

If you spend your days around metal coils and roofing crews, you’ll know the pressure: switch profiles fast, keep accuracy, avoid stoppages. That’s why the Double Layer Roll Forming Machine For Roofing Sheet keeps coming up in shop-floor conversations. Built in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, it targets one problem very directly—two roof profiles, one footprint, minimal downtime. In fact, many customers say the real win is simply fewer forklift dances and faster turnarounds.

What’s trending in roofing lines right now

Two things: versatility and energy-aware throughput. Construction schedules are tighter; developers want trapezoid today, corrugated tomorrow—without tearing down tooling. A solid double-layer line delivering around 20 m/min is the sweet spot. Not the flashiest number, but actually where yield, scrap rate, and operator sanity meet.

Key specifications (real-world values)

| Profiles | Two independent roof profiles (e.g., trapezoidal + corrugated) |

| Material | PPGI/PPGL, GI, GL, Aluminum (ASTM A653, EN 10346 grades) |

| Input coil width | ≈ 914–1250 mm (customizable) |

| Thickness | ≈ 0.3–0.8 mm (roofing typical) |

| Work capacity | 20 m/min (steady-state, profile dependent) |

| Roller stations (upper/lower) | ≈ 14–18 each, quenched/ground |

| Cutting | Hydraulic post-cut, CR12Mo blades |

| Control | PLC + HMI, length encoder, batch mode |

| Tolerance | Length ±0.5 mm; profile repeatability ±0.8 mm (typical) |

| Service life | 10–15 years with routine lubrication and roll calibration |

Process flow and quality controls

Coil loading → decoiling → leveling → dual-path forming (upper/lower cassette) → hydraulic post-cut → run-out table → stacking. Methods: cold roll forming with induction-hardened rollers, closed-loop length control, and hydraulic shear. Materials tested to ASTM A653 or EN 10346; coating checks via DFT meters; edges verified with feeler gauges. Noise typically

Before dispatch, units are dry-run tested (8-hour endurance), profile accuracy checked against CAD, and electricals validated to CE Machinery Directive practices. It sounds fussy, but that’s how scrap stays low.

Applications and why shops pick it

- Industrial roofs, warehouses, farm sheds, school blocks, rapid rebuild jobs.

- Two-in-one footprint—ideal where floor space is premium.

- Faster changeovers: switch layers via selector—no roll change. Honestly, that alone sells it.

Vendor snapshot (what buyers compare)

| Vendor | LW Roll Forming (Cangzhou) | Vendor X (South China) | Vendor Y (Overseas Integrator) |

| Speed | 20 m/min | 12–15 m/min | ≈18 m/min |

| Profile switch | Hydraulic selector, no roll change | Manual selector | Hydraulic, slower valves |

| Certifications | ISO 9001, CE | CE (declared) | ISO 9001 |

| Warranty | 18 months | 12 months | 12 months |

| Price | Mid-range | Lower | Higher |

Customization

Coil width, rib geometry, embossing, logo stamping, voltage/frequency, automatic stacker, and servo-flying shear (on request). To be honest, most teams start standard and add servo later once volumes spike.

Field notes (case snippets)

A West African roofing plant swapped two single-profile lines for one Double Layer Roll Forming Machine For Roofing Sheet. Output rose ≈18%, but the surprise was labor—three operators now cover both profiles. Another client in Eastern Europe reports length accuracy holding ±0.4 mm over 1,000-piece runs; their QC sent me the charts—boringly flat, which is great.

If you need fewer stoppages and cleaner stacks, the Double Layer Roll Forming Machine For Roofing Sheet is, I guess, the pragmatic choice—not flashy, just solid manufacturing math.

Authoritative references

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- EN 10346:2015 – Continuously hot-dip coated steel flat products.

- ISO 9001:2015 – Quality management systems.

- Directive 2006/42/EC (CE) – Machinery Safety.

- AISI S100-16 – North American Specification for the Design of Cold-Formed Steel.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025