Africa 686 IBR Roof Sheet Making Machine-Cangzhou Longway|High Production Capacity&Custom Design

Introduction

The Africa 686 IBR Roof Sheet Making Machine represents a significant advancement in the field of construction machinery. Designed to meet the evolving demands of modern infrastructure, this machine offers unparalleled efficiency, versatility, and durability. Developed by Cangzhou Longway International Trade Co., Ltd., a leading player in the manufacturing and export of industrial machinery, the Africa 686 is engineered to produce high-quality Interlocking Batten Roof (IBR) sheets with precision and speed.

As the construction industry continues to prioritize sustainability and cost-effectiveness, the Africa 686 stands out as a solution that combines cutting-edge technology with user-friendly design. This article delves into the product's core features, technical specifications, applications, and the company's commitment to innovation, all while aligning with authoritative standards such as those set by the National Institute of Standards and Technology (NIST) [1].

Product Overview

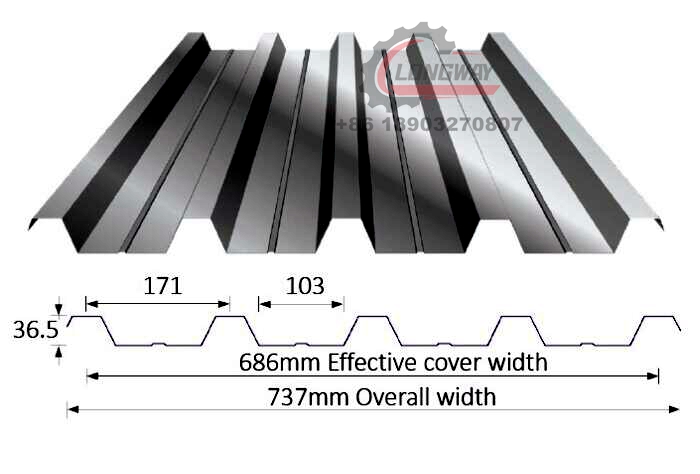

The Africa 686 IBR Roof Sheet Making Machine is a specialized roll forming system designed to produce interlocking roof sheets used in industrial and commercial buildings. These sheets are known for their strength, lightweight, and resistance to weathering, making them ideal for diverse climates. The machine's ability to accommodate both standard and custom profiles ensures flexibility for a wide range of architectural needs.

Key features of the Africa 686 include:

- High Production Capacity: The machine is optimized for large-scale manufacturing, reducing downtime and increasing output efficiency.

- Custom Design Support: Users can request tailored profiles to meet specific project requirements.

- Cost-Effectiveness: By minimizing material waste and energy consumption, the Africa 686 offers a competitive edge in production costs.

Technical Specifications

The Africa 686 is built with advanced engineering principles to ensure reliability and performance. Below is a detailed overview of its technical specifications:

| Parameter | Details |

|---|---|

| Material Compatibility | Galvanized steel, aluminum, and other lightweight metals |

| Sheet Thickness | 0.4 - 1.2 mm |

| Production Speed | Up to 15 meters per minute (adjustable) |

| Roller Diameter | 100 mm |

| Power Requirement | 380V, 50Hz, 3-phase |

| Machine Dimensions | Approx. 12m (L) x 1.5m (W) x 1.8m (H) |

| Weight | Approx. 8,000 kg |

Applications and Industry Relevance

The Africa 686 IBR Roof Sheet Making Machine is widely applicable across various sectors, including:

- Industrial Construction: Ideal for manufacturing roofs for warehouses, factories, and logistics centers.

- Commercial Buildings: Used in the production of lightweight, durable roofing for shopping malls, offices, and schools.

- Infrastructure Projects: Suitable for creating weather-resistant roofs for bridges, stadiums, and public facilities.

According to NIST's research on manufacturing technologies, "the integration of advanced roll forming systems can significantly enhance productivity and reduce material waste in construction projects" [1]. The Africa 686 exemplifies this principle, offering a solution that aligns with modern sustainability goals and industrial efficiency standards.

Company Background: Cangzhou Longway International Trade Co., Ltd.

Cangzhou Longway International Trade Co., Ltd. is a prominent Chinese manufacturer and exporter of industrial machinery, with a focus on roll forming solutions. Established with a commitment to innovation and customer satisfaction, the company has built a reputation for delivering high-quality products that meet global standards.

As a leader in the industry, Cangzhou Longway emphasizes research and development to stay ahead of market trends. The Africa 686 is a testament to the company's dedication to providing cutting-edge machinery that addresses the challenges of modern construction. For more information about the company, visit their official website.

Why Choose the Africa 686?

The Africa 686 IBR Roof Sheet Making Machine stands out in the competitive market due to its unique combination of features:

- Superior Efficiency: The machine's high-speed production capabilities ensure timely project completion.

- Customization Options: With the ability to design bespoke profiles, the Africa 686 caters to diverse architectural demands.

- Durability and Reliability: Constructed with high-quality materials, the machine ensures long-term performance with minimal maintenance.

- Cost-Effective Operation: By optimizing resource use, the Africa 686 reduces operational costs for manufacturers.

These advantages make the Africa 686 a preferred choice for businesses aiming to enhance their production capabilities while adhering to strict quality and safety standards.

Conclusion

The Africa 686 IBR Roof Sheet Making Machine is a prime example of how advanced engineering can transform the construction industry. With its robust specifications, customizable options, and cost-effective design, this machine is poised to meet the demands of modern infrastructure projects. Backed by the expertise of Cangzhou Longway International Trade Co., Ltd., the Africa 686 is a reliable solution for manufacturers seeking to elevate their production standards.

As NIST continues to drive innovation in manufacturing technologies, the Africa 686 aligns with the industry's shift toward efficiency and sustainability. For those in the construction sector, investing in this machine is a step toward future-proofing their operations.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025