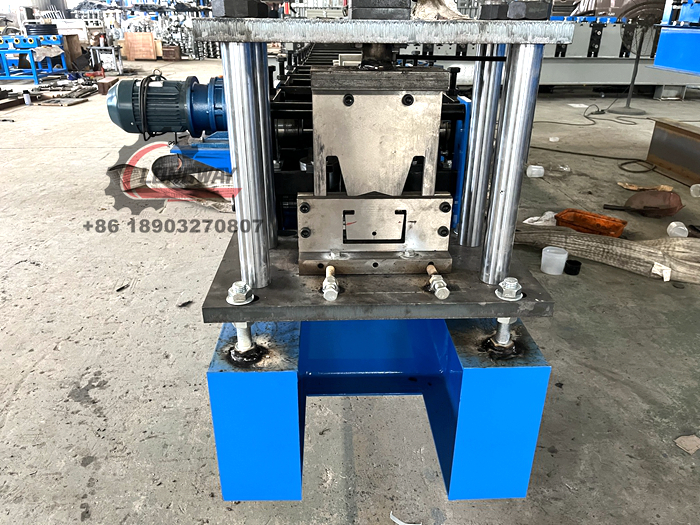

Steel C U Purlin Roll Forming Machine | High-Speed, Precise

If you’ve walked a new logistics shed lately, you’ve seen the backbone of modern roofs: crisp C and U purlins, punched cleanly, dead-straight, ready for fasten-and-go crews. That consistency doesn’t happen by accident. It’s the output of a well-tuned Steel C U Purlin Roll Forming Machine built to real-world shop pressures—tight timelines, coils that vary more than we’d like to admit, and operators who prefer simple adjustments over finicky wizardry. This line hails from SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE—a region that, to be honest, has become a quiet powerhouse for reliable roll forming.

What’s trending on shop floors

Three themes keep coming up in my interviews: quick C↔U switching, pre-punched accuracy for solar carports, and tolerance discipline even with high-strength GI (up to ~550 MPa). Many customers say they don’t need flashy automation; they want consistent 1–2 mm gauge forming, easier cleaning, and tooling that doesn’t chip if an operator sneezes.

Key specs at a glance

| Profile range | C80–C300 mm, U80–U300 mm (manual adjusting sizes) |

| Material | Galvanized steel (ASTM A653 / EN 10346), 1–2 mm; yield ≈235–550 MPa |

| Line speed | ≈10–18 m/min (real-world use may vary with punching) |

| Stations & drive | ≈14–16 stations; chain or gearbox drive per configuration |

| Cutting | Hydraulic shear; burr control |

| Control | PLC (Siemens/Delta), encoder length control, recipe library |

| Accuracy | Length ±0.5 mm/pc; straightness ≈1.0 mm/3 m; hole-to-edge ±0.3 mm |

Process flow and methods

- Decoiling (manual or hydraulic) → levelling → servo punching/notching (optional)

- Roll forming (finite-element-verified pass design, hardened tool steel ≈HRC 58–62)

- Hydraulic cut-off (flying or stop-to-cut) → runout table → bundling

Materials: GI coils Z180–Z275; common widths sized to C/U webs and flanges. Methods: crowned rolls for wave control, anti-scratch guide, coolant where needed. Service life: with weekly greasing and yearly alignment checks, I’d budget 15+ years on two-shift duty.

Testing, standards, and sample data

Factory FAT includes no-load run (≥8 h), dimensional trial with 1.5 mm GI, and burr/edge checks. Tolerances referenced to EN 10162 for cold-formed sections; material to ASTM A653 or EN 10346. Design usage aligns with AISI S100 for cold-formed structural members.

Sample run (1.5 mm GI Z275, C200): length dev. mean 0.18 mm, max 0.46 mm; straightness 0.8 mm/3 m; hole-to-hole pitch ±0.25 mm; noise 78–82 dB; scrap rate ≈0.4%.

Applications and feedback

Use cases: warehouses, retail roofs, agricultural sheds, solar carports, mezzanine frames, HVAC supports. One contractor told me, “Switching from C180 to U200 with manual dials took under 12 minutes—faster than our coil change.” Another said, surprisingly, the simplest feature—an easy-to-read handwheel scale—reduced rework more than any software tweak.

Vendor snapshot (quick compare)

| Vendor | Drive | Roll material | Certs | Lead time | Notes |

|---|---|---|---|---|---|

| LW (Cangzhou) | Chain/gearbox (option) | Cr12MoV, HRC 58–62 | ISO 9001, CE | ≈45–60 days | Manual size adjust standard; CNC optional |

| Vendor A | Gearbox | D2-equivalent | CE | ≈60–75 days | Higher capex, good for 2+ mm |

| Vendor B | Chain | 45# steel, quenched | Factory QC | ≈35–50 days | Budget option; watch tolerances |

Customization options

Profiles C80–300 and U80–300 are covered out of the box. Add-ons: servo punching matrix, quick-change cassettes, coil car, automatic stacker, oiling/antirust, language packs. Compliance packages for CE (Machinery Directive 2006/42/EC) and EN 1090 factory control are available.

If you’re speccing a new line, I guess the litmus test is simple: can it hold length at ±0.5 mm when the coil batch changes? This Steel C U Purlin Roll Forming Machine has, in my shop visits, behaved like a foreman’s friend—predictable, a bit forgiving, and not too precious about dust.

References

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- AISI S100 – North American Specification for the Design of Cold-Formed Steel Structural Members.

- EN 10162 – Cold rolled steel sections — Tolerances on dimensions and shape.

- ISO 9001:2015 – Quality management systems — Requirements.

- EN 1090-1 – Execution of steel structures — Requirements for conformity assessment.

- Directive 2006/42/EC – Machinery Directive (CE marking framework).

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025