Metal roof forming machine: High-speed, precise—Why buy?

On the Shop Floor: Real-World Notes on a metal roof forming machine

If you spend time around roofing contractors and panel fabricators (I do, sometimes too much), you start to notice a pattern: uptime and consistent geometry beat everything. That’s why the Maquina para fabricar paneles de techo 910 PV6 from SHIBAWUXING Village, Bo Town, Cangzhou, Hebei, has been quietly winning orders. It’s a straightforward, field-proven metal roof forming machine, but with a few thoughtful touches that operators actually appreciate—like sensible PLC logic and a cutter that doesn’t chew up coated steel.

Industry trends (and what matters in 2025)

The roll-forming lane is moving toward quick-change cassettes, servo flying cut, and light IoT telemetry. However, many customers say reliability and spare parts availability still trump fancy bells. In fact, the best-performing shops keep a small, robust metal roof forming machine on the line for bread‑and‑butter panels, then trial new tech on side projects. Sensible.

Core specs: 910 PV6 at a glance

| Model | Maquina para fabricar paneles de techo 910 PV6 |

| Input materials | PPGI/GI/Aluzinc; ≈0.3–0.8 mm; yield strength 235–550 MPa (real-world use may vary) |

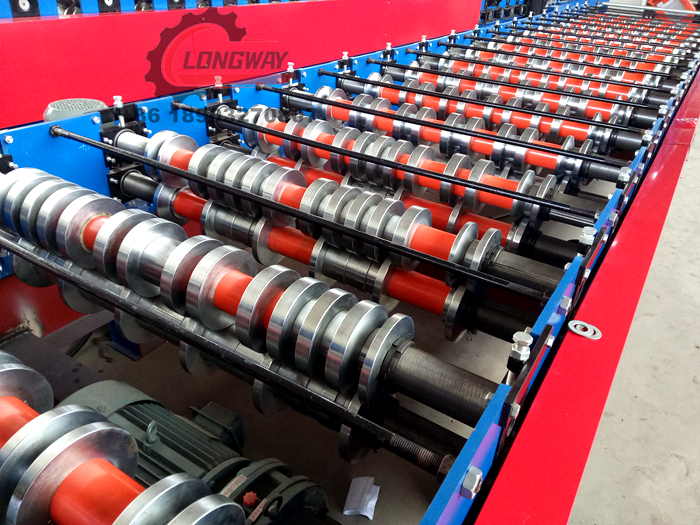

| Stations & drive | ≈14–18 stations; chain drive; hardened rollers (Cr12MoV) |

| Speed | ≈10–15 m/min (profile/steel grade dependent) |

| Cutting | Hydraulic post-cut; blade steel Cr12; burr ≈≤0.3 mm |

| Control | PLC (Siemens/Delta), HMI touch; encoder length control ±0.5 mm |

| Coil/decoiler | Manual/auto decoiler 5T; ID 508 mm; OD ≤1200 mm |

| Certs | Factory ISO 9001; CE compliance for machinery; electrical safety per EN 60204-1 |

Process flow and QA

Materials: galvanized/galvalume coil conforming to ASTM A653 or JIS G3302. Methods: decoiling → leveling → guiding → roll forming → hydraulic cutting → auto stacking. Testing: thickness via micrometer sampling, tensile per ISO 6892 (supplier), profile geometry with feeler gauges, burr check, trial runs (100 m) before handover. Service life: machine 10–15 years with quarterly lubrication; produced panels 25–40 years with proper coating and ISO 12944 paint systems. Industries: industrial roofs, cold storage, logistics centers, farm buildings, modular housing.

Where it shines

- Medium-volume roofing lines needing reliable geometry and minimal scrap- Remote project sites (simple maintenance, common spare parts)

- Contractors switching among 0.4–0.6 mm coils daily

Advantages: stable profile depth, gentle material handling (coating integrity matters), straightforward PLC recipes, and a cutter that, surprisingly, holds its edge longer than you’d expect at this price point. To be honest, that’s what operators tell me most.

Vendor comparison (quick take)

| Vendor | Origin | Lead time | PLC | After‑sales | Warranty | Price (≈) |

|---|---|---|---|---|---|---|

| LW Roll Forming (910 PV6) | Cangzhou, Hebei | 30–45 days | Siemens/Delta | Remote + onsite (by arrangement) | 12–18 months | Mid-range |

| Vendor A (regional) | South China | 25–40 days | Mitsubishi | Remote | 12 months | Low–mid |

| Vendor B (EU) | EU | 60–90 days | Siemens | Onsite network | 24 months | High |

Customization and options

Profile tweaks (crest height, pitch), embossing roll, servo length cutting, automatic stacker, oiling unit, and color inspection camera. I guess the most requested add-on is quick‑change guides for shifting between 0.45 and 0.6 mm without drama.

Case study: logistics roof, Querétaro

A contractor in Querétaro ran the 910 PV6 on 0.5 mm AZ150 coils for a 22,000 m² logistics center. Output hovered around 12 m/min, scrap under 1.2%, and panel flatness passed feeler-gauge checks with margin. Their note to me: “kept tolerance in afternoon heat,” which, honestly, is when many lines wander. That’s solid feedback for a dependable metal roof forming machine.

Safety, standards, and maintenance

Electrical safety aligns with EN 60204-1; CE declaration under the Machinery Directive. Use coils certified to ASTM A653 or JIS G3302, and verify tensile values. Quarterly checks: chain tension, bearing grease, hydraulic oil cleanliness (NAS 9 or better), and blade edge wear. Keep it boring; get long service life.

References

- ISO 9001:2015 Quality Management Systems.

- EN 60204-1: Safety of machinery—Electrical equipment.

- ASTM A653/A653M: Standard Specification for Steel Sheet, Zinc-Coated.

- ISO 6892-1: Metallic materials—Tensile testing—Method of test at room temperature.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025