C18 Roof Machine: High-Speed Precision for Metal Roofing?

Field Notes on the [c18 roof machine] and Why Fabricators Keep Asking for It

If you spend any time in roll-forming shops from Hebei to Jakarta, you hear the same thing: keep the profile consistent, don’t baby the coils, and for goodness’ sake, make the controls straightforward. The T18 C18 Metal roofing machine—known on the shop floor simply as the c18 roof machine—checks those boxes. Built in SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE, it’s a pragmatic workhorse with a bit of polish. I’ve watched it run panels all afternoon with minimal fiddling, which is rarer than it should be.

What it is, technically

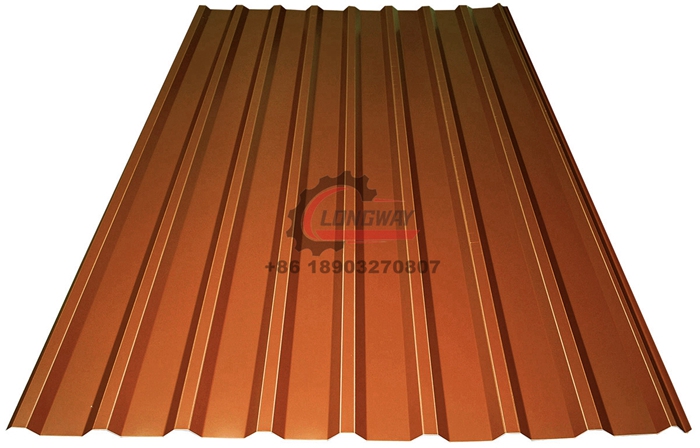

It’s a T18/C18 roof sheet roll former—profile variants that are popular for warehouses, light commercial roofs, and fast retrofit projects. The c18 roof machine forms pre-painted steel (PPGI), galvanized (GI), and galvalume coils (AZ) in the 0.3–0.8 mm range, with a yield strength up to ≈550 MPa. The line integrates decoiling, leveling, roll stations, optional bead/rib pressing, hydraulic post-cut, and a simple PLC HMI. Nothing exotic, which is exactly the point.

Typical specifications

| Profiles | T18 / C18 roof sheet |

| Material | PPGI, GI (ASTM A653 / EN 10346), AZ (AZ150) |

| Thickness | ≈0.3–0.8 mm (real-world use may vary) |

| Coil width | 1000–1250 mm |

| Yield strength | 235–550 MPa |

| Forming stations | 14–18 (custom by profile) |

| Roller material | 45# steel with hard chrome; cutter CR12MoV quenched |

| Line speed | 10–18 m/min |

| Drive | 5.5–7.5 kW motor, chain drive |

| Control | PLC (Siemens/Delta), encoder length control ±0.5 mm |

| Power | 380V 50Hz 3Ph (other voltages optional) |

| Service life | 8–12 years with standard maintenance |

Process flow and quality checks

Decoiler → leveling → guided feeding → roll forming → rib/emboss (optional) → hydraulic post-cut → runout table. QC includes profile tolerance checks (feeler gauge), length accuracy via encoder audit (±0.5 mm typical), cutter hardness verification (HRC ≈58–62), and salt-spray validation of sample panels to ASTM B117 (e.g., 240 h on AZ150). Electrical safety aligns with IEC 60204-1. Many customers say the c18 roof machine holds crown and side-lap tidy even on 0.4 mm coils—provided the coil is decent.

Where it fits

- Industrial warehouses and logistics hubs

- Agri-roofing and rural workshops (fast installs, low waste)

- Disaster-rebuild roofs in typhoon and cyclone corridors

Customization and options

Voltage changes, anti-scratch polyurethane rollers, logo embossing, quick-change spacers, servo fly-cut for higher throughput, and coil car upgrades. To be honest, the base spec is already solid; options help if you’re chasing volume or brand identity.

Vendor snapshot

| Vendor | Lead time | Certs | Warranty | Notes |

| LW Roll Forming (Cangzhou) | 25–35 days | ISO 9001, CE | 18 months | Good remote commissioning; steady spares |

| EU Import Brand | 45–60 days | CE | 12 months | Higher price; nice HMI |

| Local Workshop | 15–25 days | — | 6 months | Lowest cost; variable QC |

Case story: Cebu rebuild, 2023

A contractor in Cebu ran a c18 roof machine on 0.47 mm AZ150 coils for post-typhoon projects. Average output: ≈4,500 m/day at 16 m/min. Recorded downtime was ≈1.2%/shift after the first week (mostly coil changes). Panels passed random length checks within ±0.5 mm and maintained clean side-laps. Payback: 7 months. As they told me, “it just keeps the profile straight.” Simple praise, but meaningful.

Standards and compliance

Material inputs typically conform to ASTM A653 or EN 10346; color-coated per GB/T 12754. Tensile checks per ISO 6892-1; general tolerances ISO 2768-mK. Electrical safety guided by IEC 60204-1. Factory QA operates under ISO 9001. It seems routine, but these guardrails keep the panels consistent when projects get hectic.

Citations

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025