Automatic Drywall Steel L Angle Bar Roll Forming Machine

Introduction to Advanced Roll Forming Technology

In the rapidly evolving landscape of construction and industrial manufacturing, precision engineering is paramount. The demand for robust, efficient, and cost-effective solutions drives innovation in machinery. Central to the modern drywall industry is the efficient production of steel L angle bars, critical components for framing and structural integrity. This article delves into the capabilities and significance of the Drywall Steel L Angle Bar forming machine, an essential asset for high-volume, high-precision manufacturing.

These sophisticated machines are engineered to transform raw steel coils into perfectly formed L-shaped profiles, meeting stringent industry specifications. They represent the pinnacle of automated roll forming technology, offering unparalleled consistency, speed, and material utilization. Understanding the intricate details of their operation, technical specifications, and application advantages is crucial for B2B decision-makers seeking to optimize their production lines and enhance product quality.

Industry Trends and Market Dynamics

The global construction market continues its upward trajectory, with a strong emphasis on modular construction, prefabrication, and sustainable building practices. This growth directly fuels the demand for efficient production of construction materials. Key trends influencing the roll forming sector include:

- Automation and Industry 4.0 Integration: Manufacturers are increasingly adopting fully automated systems with integrated sensors, AI-driven predictive maintenance, and real-time data analytics. This enhances operational efficiency, reduces labor costs, and minimizes downtime.

- Sustainable Manufacturing: There is a growing push for machines that offer superior material yield rates, reduced energy consumption, and the ability to process recycled or sustainable material grades. This aligns with global environmental regulations and corporate social responsibility initiatives.

- Higher Precision and Customization: Modern construction demands tighter tolerances and more complex profiles. Machines are being designed with advanced control systems (e.g., Siemens, Mitsubishi PLCs) to achieve sub-millimeter precision and allow for rapid tooling changes for customized profiles.

- Global Supply Chain Resilience: The market is adapting to geopolitical shifts and supply chain vulnerabilities, leading to more localized production facilities and a greater emphasis on reliable, high-performance machinery that can operate consistently under various conditions.

These trends underscore the importance of investing in advanced roll forming solutions that are not only productive but also adaptable to future market demands. The ability to produce high-quality drywall steel L angle bars efficiently directly impacts project timelines and overall construction costs.

Detailed Process Flow of the Drywall Steel L Angle Bar Forming Machine

The manufacturing of L angle bars via roll forming is a highly efficient cold-forming process. The Drywall Steel L Angle Bar forming machine meticulously shapes metal coils through a series of rollers. Below is a detailed breakdown of the typical process flow:

1. Material Preparation:

The process begins with high-grade steel coils, typically galvanized steel (e.g., G30, G60, G90) or cold-rolled steel, offering excellent corrosion resistance and structural integrity. Common material thicknesses range from 0.3 mm to 1.2 mm, depending on the required load-bearing capacity and application. The coil is loaded onto a decoiler (uncoiler) which feeds the material smoothly into the machine.

2. Shearing/Leveling:

Before forming, the steel strip often passes through a leveling device to ensure flatness, removing any coil set or material inconsistencies. Some machines include a pre-shearing unit to trim the leading edge of the coil or to cut the strip to a precise initial width if required for specific profiles.

3. Roll Forming Stations:

This is the core of the process. The flat steel strip progressively passes through a series of precisely engineered roller dies (forming stations). Each station gradually bends the metal incrementally, without applying heat (cold forming), until the desired L-shaped profile is achieved. The number of forming stations varies based on the complexity of the profile and material thickness, typically ranging from 8 to 18 stations for L angle bars. The rollers themselves are often made from high-grade tool steel (e.g., Cr12, SKD11) and are heat-treated (quenched and tempered to HRC 58-62) for exceptional wear resistance and long service life. This reduces the need for frequent maintenance and tooling replacement.

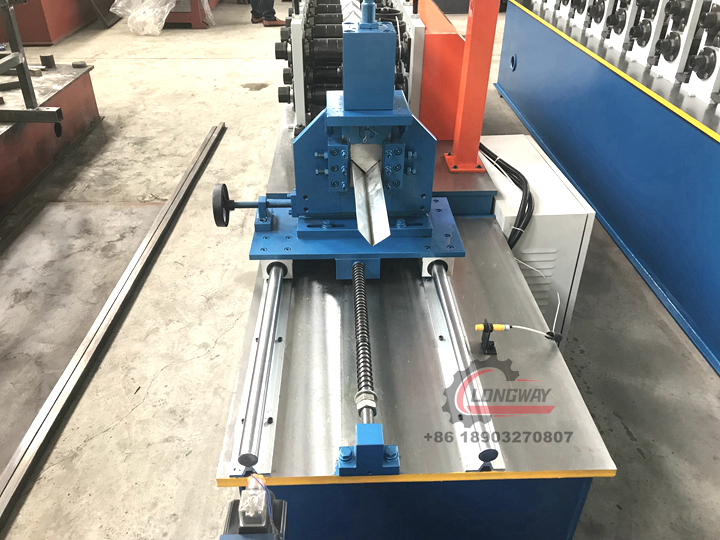

4. Cutting to Length:

Once the L angle bar is fully formed, it moves to a cutting unit. This can be a hydraulic post-cutting system, flying shear, or servo-driven cutting mechanism, ensuring precise cuts to the pre-programmed lengths without stopping the forming process. The cutting dies are also manufactured from durable tool steel for longevity.

5. Output and Stacking:

The finished L angle bars are then discharged onto an output table, often equipped with an automated stacking or collection system. This minimizes manual handling and prepares the finished products for packaging and distribution.

6. Quality Control and Testing:

Throughout the process, stringent quality control measures are applied. Key parameters such as profile dimensions, straightness, angle accuracy, and cut length are continuously monitored. Finished products undergo final inspection to ensure compliance with international standards like ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material specifications, and ANSI (American National Standards Institute) for dimensional tolerances. Non-destructive testing methods may be employed to ensure material integrity. The estimated service life of well-maintained roll forming machines, particularly the forming rollers, typically exceeds 15-20 years with proper care and regular maintenance, largely due to the robust material selection and precise manufacturing processes involved in components like shafts (often 45# steel, quenched and tempered) and gearboxes (precision-machined for minimal backlash).

This robust process flow ensures that the L angle bars produced are consistently high quality, ready for immediate integration into various construction and industrial applications.

Key Technical Specifications

The performance and output quality of a Drywall Steel L Angle Bar forming machine are defined by its technical specifications. These parameters are crucial for assessing machine suitability for specific production requirements and ensuring optimal operational efficiency. Understanding these details enables effective planning for material sourcing, energy consumption, and facility integration.

| Parameter | Specification | Notes |

|---|---|---|

| Material Thickness Range | 0.3 - 1.2 mm (typ.) | Adjustable for various gauges |

| Material Type | Galvanized Steel (GI), Cold Rolled Steel (CR) | Yield strength up to 550 MPa |

| Forming Speed | 15 - 30 meters/min (adjustable) | Depends on profile complexity and material |

| Number of Forming Stations | 8 - 18 stations | Optimized for gradual forming |

| Roller Material | Cr12 (SKD11 equivalent), Quenched & Tempered | Hardness HRC 58-62 for durability |

| Main Motor Power | 5.5 - 11 kW (VFD controlled) | Energy-efficient operation |

| Cutting System | Hydraulic Post-Cutting/Flying Shear | Tolerance +/- 1mm |

| Control System | PLC (Siemens/Mitsubishi/Delta) with Touch Screen HMI | User-friendly interface, diagnostic capabilities |

| Total Power | Approx. 15-25 kW (varies) | Includes main motor, hydraulic, and control power |

| Machine Dimensions (LxWxH) | Approx. 6000-8000 x 1200 x 1500 mm | Excluding decoiler and output table |

These specifications highlight the machine's capacity for precise and efficient production. Features like VFD-controlled motors (Variable Frequency Drive) ensure optimal speed control and significant energy savings, typically ranging from 15-30% compared to traditional constant-speed motors. The PLC control system, often from reputable brands like Siemens or Mitsubishi, provides real-time monitoring, diagnostic feedback, and allows for quick adjustments to production parameters, minimizing material waste and maximizing throughput.

Application Scenarios Across Industries

The versatility of L angle bars makes them indispensable across a multitude of industries. A Drywall Steel L Angle Bar forming machine serves as the backbone for producing these critical components, facilitating robust and reliable construction in diverse applications. Target industries include:

- Construction & Drywall Framing: This is the primary application. L angle bars are extensively used as corner beads, edge trims, and reinforcement elements in drywall systems. They provide structural integrity, protect edges from impact, and create clean, sharp corners. Their precise dimensions ensure seamless integration with plasterboard and other walling materials.

- HVAC Systems: In heating, ventilation, and air conditioning installations, L angle bars are used for ductwork support, framing for air handling units, and general structural reinforcement, especially where custom angles are required for intricate designs.

- Solar Panel Mounting Systems: The robust and weather-resistant properties of galvanized steel L angles make them ideal for framing and support structures in solar panel installations, providing durability against environmental elements.

- Warehouse Racking & Storage: L angle bars are fundamental in constructing shelves, racks, and other storage solutions due to their strength-to-weight ratio and ease of assembly.

- General Industrial Fabrication: Used as components in machinery frames, equipment supports, and custom fabrication projects where lightweight yet strong angular profiles are needed.

- Telecommunications & Data Centers: For cable management systems, equipment enclosures, and structural supports within controlled environments.

Advantages in Typical Application Scenarios:

- Energy Efficiency in Building (Drywall): By providing perfectly straight and dimensionally accurate framing, L angle bars produced by these machines contribute to tighter building envelopes, reducing air leakage and enhancing thermal performance, leading to energy savings for end-users.

- Corrosion Resistance (Outdoor/Wet Environments): Utilizing galvanized steel input material, the L angle bars exhibit superior corrosion resistance, making them ideal for exterior applications or humid indoor environments without requiring additional protective coatings post-forming, thus extending the service life of structures. This is a critical advantage in regions with varying climates or for applications in water supply & drainage facilities.

- Structural Integrity (Warehouse Racking): The consistent material properties and precise bending ensure that each L angle bar possesses uniform structural integrity, crucial for safety and load-bearing capacity in heavy-duty applications like warehouse racking, preventing failures and improving operational safety.

- Cost-Effectiveness & Speed (General Construction): The high production speed and minimal material waste inherent in roll forming translate directly into lower per-unit costs. This efficiency is critical for large-scale construction projects where speed of material supply directly impacts project timelines and overall budget.

Technical Advantages and Performance Metrics

The advanced engineering of a modern Drywall Steel L Angle Bar forming machine offers numerous technical advantages that translate into superior product quality, operational efficiency, and long-term cost savings. These machines are designed for high performance under continuous operation.

- Precision Roll Forming: Unlike traditional braking or bending methods, roll forming ensures extremely tight tolerances on dimensional accuracy (typically ±0.5 mm on length, ±0.2 mm on width/angle). This precision is critical for seamless integration into construction projects and reduces on-site rework.

- High Production Speed: With forming speeds reaching up to 30 meters per minute, these machines can rapidly produce large volumes of L angle bars, meeting the demands of large-scale projects and high-volume manufacturing. This significantly reduces lead times and improves overall project velocity.

- Material Optimization: The cold forming process minimizes material waste. Advanced software-driven control systems can optimize cutting patterns and monitor material usage, leading to significant reductions in scrap material, typically less than 3% compared to up to 10-15% for other methods.

- Energy Efficiency: Modern machines are equipped with Variable Frequency Drives (VFDs) for main motors and energy-efficient hydraulic systems. This leads to a measurable reduction in power consumption, often lowering operational electricity costs by 20-30% compared to older, less optimized equipment.

- Exceptional Durability and Service Life: Critical components, such as forming rollers and cutting dies, are fabricated from hardened tool steels (e.g., Cr12Mov, D2 steel equivalent) and undergo precision CNC machining and heat treatment (HRC 58-62). This ensures exceptional wear resistance, reducing maintenance intervals and extending component service life beyond 10 years for rollers and dies.

- Automated Control and Diagnostics: Integrated PLC systems with touch-screen Human-Machine Interfaces (HMIs) provide intuitive control, real-time status monitoring, and comprehensive diagnostic capabilities. This facilitates quick troubleshooting, minimizes operator error, and allows for remote monitoring and software updates, significantly enhancing operational reliability.

- Surface Quality Preservation: The gradual forming process minimizes stress on the material, preserving the integrity of protective coatings (e.g., galvanization). This prevents micro-cracking and flaking, ensuring the L angle bars maintain their corrosion resistance and aesthetic quality.

These combined technical advantages underscore the investment value of an advanced roll forming machine, making it a critical asset for businesses focused on productivity, quality, and sustainable manufacturing practices.

Vendor Comparison: Selecting the Right Partner

Choosing a supplier for a Drywall Steel L Angle Bar forming machine involves more than just comparing price tags. It requires a thorough evaluation of vendor capabilities, technological offerings, after-sales support, and long-term partnership potential. While specific company names are beyond the scope of this general discussion, we can outline key comparison criteria and typical offerings.

| Feature Category | Standard Vendor Offering | Premium Vendor Offering |

|---|---|---|

| Control System | Basic PLC, push-button controls | Advanced PLC (Siemens/Mitsubishi), HMI touch screen, remote access, diagnostic tools |

| Forming Rollers | 45# steel, surface hardened | Cr12/SKD11 tool steel, full heat treatment (HRC 58-62), precision CNC machining |

| Cutting System | Hydraulic post-cutting, fixed speed | Servo-driven flying shear, variable speed, precise length control (e.g., ±0.5 mm) |

| Production Speed | 10-20 m/min | 25-40 m/min (depending on profile) |

| After-Sales Support | Limited warranty, basic spare parts, on-site installation optional | Extended warranty, comprehensive spare parts inventory, remote diagnostics, global on-site support, training programs |

| Customization | Basic adjustments to length/speed | Full profile design support, material compatibility adjustments, integrated punching/notching, automated stacking solutions |

When evaluating vendors, prospective buyers should also consider their experience and certifications. Reputable manufacturers often hold ISO 9001 certifications, demonstrating a commitment to quality management systems. Partnerships with globally recognized component suppliers (e.g., Rexroth for hydraulics, SKF for bearings) are strong indicators of reliability. A vendor's track record, including customer testimonials, long-standing client relationships, and years in the industry, provides valuable insights into their trustworthiness and product performance.

Customized Solutions for Specific Needs

Recognizing that no two manufacturing operations are identical, leading providers of Drywall Steel L Angle Bar forming machines offer extensive customization options. These tailored solutions ensure that the machinery integrates seamlessly into existing production lines and meets unique operational demands, optimizing efficiency and profitability.

- Profile Design & Tooling: Custom L angle profiles can be developed to specific dimensions, flange lengths, and web thicknesses. This includes designing and manufacturing specialized roller dies (tooling) for unique architectural or structural requirements, accommodating both standard galvanized steel and other alloys.

- Material Handling Systems: Integration with custom decoilers for heavier coils, automated feeding systems, pre-punching units for specific hole patterns, and automated stacking/bundling systems at the output end to reduce labor and improve throughput.

- Speed and Production Capacity: Machines can be configured for ultra-high-speed production for markets with immense demand or optimized for lower volume, high-precision niche applications. This involves adjusting motor power, gear ratios, and control system programming.

- Advanced Control Features: Options include integration with factory ERP systems, remote diagnostics and maintenance support, real-time production monitoring dashboards, and advanced safety interlocks compliant with specific regional regulations (e.g., CE, OSHA).

- Environmental Adaptations: Customization for extreme operating environments, such as high humidity, dust, or specific temperature ranges, with appropriate material selection, sealed components, and specialized lubrication systems.

- Integrated Secondary Operations: Beyond just forming and cutting, machines can incorporate in-line punching, notching, embossing, or marking units to create multi-functional components in a single pass, significantly reducing post-processing steps.

Engaging with a vendor that has robust R&D capabilities and a track record in custom engineering is paramount for capitalizing on these opportunities. Collaborative design processes ensure that the final machine precisely matches the client's operational goals and delivers maximum return on investment.

Application Case Studies

Real-world application demonstrates the tangible benefits and capabilities of advanced roll forming machinery. Here are illustrative case studies highlighting the impact of a Drywall Steel L Angle Bar forming machine in various settings.

Case Study 1: Large-Scale Residential Development in the Middle East

A leading construction material supplier in the UAE was tasked with providing millions of linear meters of galvanized steel L angle bars for a sprawling residential complex. Their existing production capacity was insufficient, and manual bending methods yielded inconsistent quality and high material waste. After investing in a high-speed, fully automated Drywall Steel L Angle Bar forming machine with an integrated flying shear, the client achieved a 300% increase in production output. Material waste was reduced from an average of 8% to less than 2%, primarily due to precise cutting and optimized forming profiles. The uniformity of the L angles significantly reduced installation time on-site, leading to a 15% reduction in overall labor costs for the framing stage of the project. This successful deployment led to the client becoming the preferred supplier for several subsequent mega-projects in the region, largely attributable to the reliability and consistency delivered by the advanced roll former.

Case Study 2: Precision Manufacturing for HVAC Ducting in Europe

A specialized HVAC manufacturer in Germany required custom L angle profiles for an innovative modular ducting system. The specifications demanded exceptionally tight tolerances (±0.1 mm) and a smooth, scratch-free surface finish to ensure optimal airflow and aesthetics. Their conventional roll forming machine struggled to meet these precise requirements consistently. By upgrading to a machine featuring advanced servo-motor control for the forming stations and an optimized roller design with polished Cr12 tooling, they were able to produce the complex profiles with the required accuracy. The new machine's capability to integrate a fine-tuning system allowed for micro-adjustments during operation, resulting in virtually zero defect rates on the critical dimensions. This allowed them to secure exclusive contracts for high-end commercial HVAC projects, reinforcing their reputation for quality and innovation.

Case Study 3: Remote Mining Infrastructure in Australia

For a remote mining operation in Western Australia, there was a critical need for durable L angle supports for various temporary and semi-permanent structures, including equipment sheds and cable trays. The environment was highly corrosive and subjected to extreme temperature fluctuations. A robust Drywall Steel L Angle Bar forming machine, specially configured with enhanced anti-corrosion components and a ruggedized control panel for outdoor use, was deployed. The machine's ability to process heavy-gauge galvanized steel (1.0mm thickness) at consistent speeds, while maintaining structural integrity, proved invaluable. Furthermore, the supplier provided comprehensive remote diagnostic support, minimizing downtime in a challenging logistical environment. The client reported a significant improvement in the longevity of their infrastructure, with angle bars showing no signs of critical degradation after five years, directly attributable to the quality of material processing and machine reliability.

Trustworthiness: FAQs, Lead Time, Warranty & Support

Building trust with B2B clients requires transparency and robust commitment to service and quality. This section addresses common inquiries and outlines the framework for a reliable partnership.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for a custom Drywall Steel L Angle Bar forming machine?

A1: Standard machine configurations typically have a lead time of 45-60 business days from order confirmation. For highly customized machines involving specialized tooling or unique integrations, the lead time can range from 75-120 business days, depending on the complexity of design and component sourcing. Specific timelines will be provided with a detailed quotation.

Q2: What kind of pre-sales and post-sales support can I expect?

A2: Pre-sales support includes comprehensive consultation, profile design assistance, factory layout recommendations, and detailed technical specifications. Post-sales support encompasses machine installation and commissioning, operator training (on-site or remote), a readily available spare parts inventory, and responsive technical assistance via phone, email, and video conferencing. On-site technical visits can be arranged as needed.

Q3: How difficult is it to change the profile on the machine?

A3: For machines designed for specific L-angle profiles, changing the profile typically requires changing out the entire set of forming rollers. While this is a technical task, modern machines are designed with quick-change tooling systems to minimize downtime. The process can take anywhere from 4 to 8 hours depending on machine design and operator experience. For machines designed to produce a range of similar L-angles with minor adjustments, changeover can be much quicker, often within an hour.

Q4: Are your machines compliant with international safety standards?

A4: Yes, our machines are designed and manufactured to meet or exceed relevant international safety standards such as CE (for European markets) and OSHA guidelines (for North American markets). We incorporate features like emergency stop buttons, safety guarding, interlocking doors, and clear warning labels to ensure safe operation. Compliance certificates are available upon request.

Lead Time & Fulfillment Details

Upon finalization of machine specifications and receipt of the initial deposit, a detailed production schedule is provided. Our manufacturing process, from raw material procurement (e.g., high-grade steel for rollers, brand-name PLCs) to final assembly and testing, is meticulously managed. Regular updates on the machine's progress are communicated to the client. Prior to shipment, a factory acceptance test (FAT) can be conducted, either in person by the client or via remote video conferencing, to verify all functional and performance parameters. Packaging for international transit adheres to ISPM 15 standards, ensuring safe delivery.

Warranty Commitments

We offer a comprehensive warranty, typically 12 to 24 months from the date of installation or 18 to 30 months from the date of shipment, whichever comes first. This warranty covers manufacturing defects in materials and workmanship for all major machine components. Specific wear parts, such as forming rollers and cutting dies, may have a separate, extended warranty based on throughput or years of service, contingent on regular maintenance schedules. Extended warranty plans and preventative maintenance contracts are also available to provide long-term peace of mind and minimize unexpected operational costs.

Customer Support & After-Sales Service

Our commitment extends well beyond the sale. A dedicated team of technical support engineers is available to provide assistance. This includes:

- 24/7 Remote Technical Support: Troubleshooting and guidance via phone, email, and secure remote access to the machine's PLC for diagnostics.

- On-site Installation and Training: Experienced technicians travel to your facility for machine setup, commissioning, and hands-on training for your operators and maintenance staff.

- Spare Parts Management: A robust inventory of genuine spare parts is maintained for immediate dispatch, ensuring minimal downtime in case of component failure.

- Preventative Maintenance Programs: Tailored service plans to maximize machine uptime and extend operational life, including routine inspections and component replacement.

- Software Updates: Regular firmware and software updates for the control system, ensuring the machine benefits from the latest operational enhancements and security patches.

Our aim is to forge long-term partnerships, ensuring your roll forming machine operates at peak performance throughout its extensive service life.

Conclusion

The modern Drywall Steel L Angle Bar forming machine stands as a testament to precision engineering and automated manufacturing. Its ability to consistently produce high-quality, dimensionally accurate L angle bars at speed, while optimizing material use and energy consumption, makes it an indispensable asset for a wide array of industries. From meeting the rigorous demands of large-scale construction projects to providing customized solutions for niche applications, these machines offer a robust, reliable, and efficient pathway to production excellence. Investing in such advanced technology is not merely a purchase but a strategic commitment to enhancing productivity, ensuring product quality, and maintaining a competitive edge in today's dynamic global market.

References

- Roll Forming Handbook. (2018). American Iron and Steel Institute (AISI). Retrieved from www.steel.org

- Cold Roll Forming of Sections: A Comprehensive Guide. (2020). European Coil Coating Association (ECCA). Retrieved from www.ecca.org

- ASTM International Standards for Steel Products, A653/A653M - Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. (2023). Retrieved from www.astm.org

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements. (2015). Retrieved from www.iso.org

- Manufacturing Process Fundamentals. (2017). Kalpakjian, Serope, and Steven R. Schmid. Pearson Education.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025