0.85mm Top hat Roof Batten Omega Roll Forming Machine | Fast

0.85mm Top Hat Roof Batten Omega Roll Forming Machine is a key solution in the manufacturing industry, specifically within Manufacturing of metal processing machinery and Manufacturing of roll forming equipment. This article explores how CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- 0.85mm Top Hat Roof Batten Omega Roll Forming Machine Overview

- Benefits & Use Cases of 0.85mm Top Hat Roof Batten Omega Roll Forming Machine in Manufacturing of roll forming equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on 0.85mm Top Hat Roof Batten Omega Roll Forming Machine from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

0.85mm Top Hat Roof Batten Omega Roll Forming Machine Overview

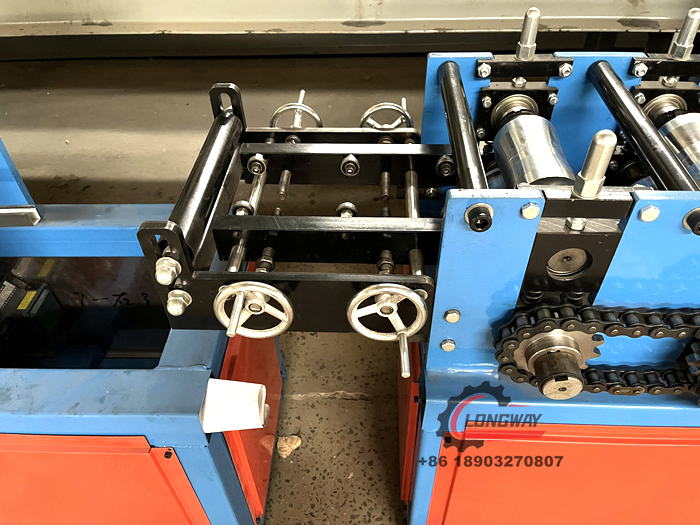

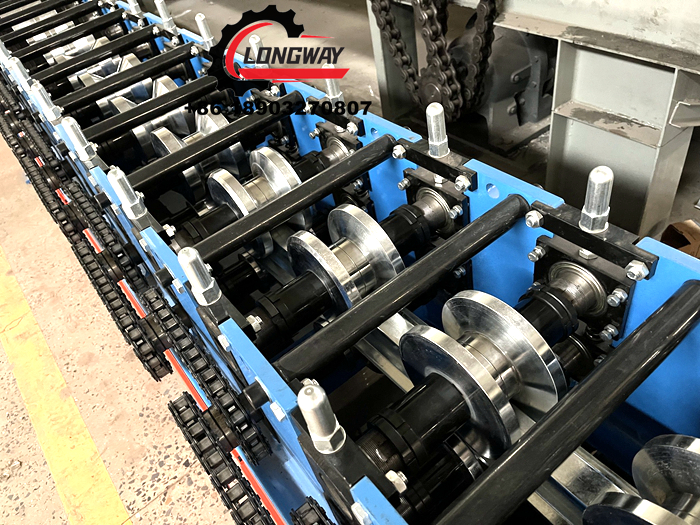

Engineered for roofing and light-steel framing producers, the 0.85mm Top Hat Roof Batten Omega Roll Forming Machine converts galvanized coil into consistent top-hat/omega sections with high throughput and minimal scrap. In the context of Manufacturing of metal processing machinery and Manufacturing of roll forming equipment, this line represents a precise, automated path from coil to finished batten profiles used in roof purlin support, cladding sub-structures, and interior furring systems. Typical configurations include decoiler, straightener, roll forming stations, in-line punching (optional), post-cut guillotine, run-out tables, and a PLC/HMI for recipe-based production. Optimized for 0.85 mm material, the machine can be configured for adjacent thickness ranges (subject to material grade and yield strength). Line speeds are typically engineered to match your downstream needs and quality targets, ensuring balance between accuracy and productivity.

- Relevant for continuous, high-volume production of roof battens and omega channels demanded by builders, distributors, and OEM component suppliers.

- Technical highlights can include servo length control, quick recipe changeovers, and robust roll tooling tailored to your top-hat/omega geometry.

- CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD is a proven manufacturer and integrator, supporting specification, tooling design, installation, and after-sales service for global buyers.

Benefits & Use Cases of 0.85mm Top Hat Roof Batten Omega Roll Forming Machine in Manufacturing of roll forming equipment

Across roofing component factories and steel building systems, standardized battens and omega channels underpin consistent roof spans and cladding performance. This machine enables lights-out repeatability: stable web heights, accurate flange widths, and tight length tolerances that reduce rework at job sites. With coil-fed efficiency, B2B decision makers benefit from predictable yield and faster order fulfillment. Optional punching units streamline bracket, fastener, or drainage holes in-line, removing secondary operations. For OEMs building their own roll forming cells, integrating this system can expand product families without adding floor-space-intensive manual processes. Competitive advantages often include modular roll stations for profile tweaks, durable tool steel rolls for extended life, and a user-friendly PLC for storing multi-profile recipes. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD leverages deep application experience to align machine geometry, material specs, and expected duty cycles, ensuring your 0.85mm Top Hat Roof Batten Omega Roll Forming Machine delivers reliable, specification-compliant parts shift after shift.

- Applications: roof batten manufacturing, omega-profile sub-structures for cladding, furring channels, and light framing accessories.

- Advantages: stable production speed, waste minimization, in-line punching/cutting, and consistent dimensional accuracy for easy site assembly.

- Backed by CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD’s design, commissioning, and operator training services.

Cost, Maintenance & User Experience

Total cost of ownership for a 0.85mm Top Hat Roof Batten Omega Roll Forming Machine hinges on uptime, scrap rate, energy draw, and tooling longevity. By consolidating forming, punching, and cutting in one pass, you cut work-in-process, labor touches, and secondary fixtures. Preventive maintenance—daily cleaning, lubrication, fastener checks, and scheduled roll alignment—helps maintain tolerance integrity, extending tooling life and protecting ROI. Many buyers see accelerated payback when replacing manual or press-brake steps, driven by improved throughput and 1–2% scrap reductions. Operators appreciate intuitive HMI recipes, automatic length setting, and clear fault diagnostics that shorten changeovers and reduce training time. Feedback from manufacturers in the metal processing machinery sector points to stable dimensional repeatability and fewer field complaints, translating into lower warranty exposure and healthier margins. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports the full lifecycle with spare parts packages, remote technical guidance, and commissioning services to keep the line producing to target KPIs.

- Durability: robust frame and roll tooling designed for continuous-duty cycles with 0.85 mm galvanized steel.

- ROI drivers: reduced rework, fewer secondary ops, and faster cycle times across mixed-length orders.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping metal forming investments. Roofing supply chains increasingly favor designs that maximize coil utilization and minimize scrap. Efficient roll forming for omega and top-hat battens reduces offcuts and encourages recycling at the coil level. With growing emphasis on green building standards, manufacturers are optimizing energy usage, upgrading drives and hydraulics, and prioritizing closed-loop lubrication to lessen environmental impact. Market demand for light-gauge steel solutions continues to rise due to speed of installation, weight advantages, and consistent quality. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD positions its equipment to help customers align with evolving regulations and quality frameworks while focusing on throughput and reliability. From consultative profile engineering to process optimization, the company’s forward-thinking approach supports sustainable output without compromising on dimensional accuracy or production speed.

- Trends: higher automation, digital diagnostics, material-light designs, and integrated in-line operations.

- LONGWAY’s solutions emphasize efficiency, scrap reduction, and dependable quality for long-term competitiveness.

Conclusion on 0.85mm Top Hat Roof Batten Omega Roll Forming Machine from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

The 0.85mm Top Hat Roof Batten Omega Roll Forming Machine delivers consistent, high-volume production for roofing and cladding supply chains, aligning with the demands of Manufacturing of metal processing machinery and Manufacturing of roll forming equipment. By combining robust mechanics, precise tooling, and user-friendly controls, it helps manufacturers scale capacity and reliability. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD’s engineering support, commissioning, and after-sales service make it a trusted partner for global B2B buyers.

- Value recap: accuracy, uptime, and streamlined operations for top-hat and omega battens at 0.85 mm.

- Reputation: a reliable supplier for tailored roll forming solutions.

- Strong CTA: Contact us: email: rebecca@longwaymachinery.com — Visit our website: https://www.lwrollformingmachine.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025