Leading Manufacturers of Z Purlin Forming Machines for Superior Construction Solutions

Z Purlin Forming Machine Manufacturers A Comprehensive Overview

In the realm of modern construction and manufacturing, the use of structural steel components such as Z purlins has gained paramount importance. Z purlins are widely utilized in the construction of buildings, particularly in metal structures, due to their superb strength-to-weight ratio and versatility. As the demand for Z purlins continues to rise, the role of efficient and reliable Z purlin forming machines becomes increasingly significant. This article delves into the landscape of Z purlin forming machine manufacturers, highlighting their importance, functions, and the factors influencing the choice of a manufacturer.

Understanding Z Purlin Forming Machines

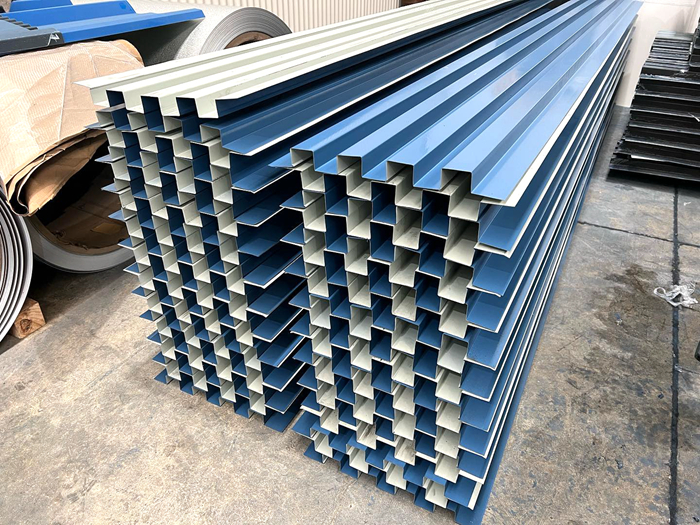

Z purlin forming machines are specialized equipment designed to manufacture Z-shaped steel sections from sheet metal. The process typically involves feeding flat steel sheets into the machine, which then shapes them into Z purlins through various forming stations. These machines are valued for their capability to produce purlins with high accuracy and efficiency, ensuring the final product meets specific structural requirements.

Key Features of Z Purlin Forming Machines

A typical Z purlin forming machine is equipped with several essential features

1. High Precision Accuracy in forming is crucial, as any deviations can compromise the structural integrity of the building. Quality manufacturers ensure their machines come with advanced CNC technology for precise control.

2. Customization Capacity Z purlin specifications can vary greatly depending on the construction project. Reputable manufacturers offer customizable solutions, allowing clients to adjust width, thickness, and length as needed.

3. Durability and Quality Materials The best machines are constructed from high-quality materials that ensure longevity and reduced maintenance costs. This is vital for factories that rely on heavy-duty operations.

4. User-Friendly Operation Modern Z purlin forming machines come with intuitive interfaces and automation capabilities, making them easier to operate and reducing the risk of human error.

5. Production Speed Efficient machines can significantly increase output, with some capable of producing hundreds of purlins per hour, thereby enhancing productivity and profitability for manufacturers.

Leading Manufacturers in the Industry

z purlin forming machine manufacturers

Several prominent manufacturers have established themselves as leaders in the production of Z purlin forming machines. Companies like Zhangjiagang Dingsheng Machine Manufacturing Co., Ltd., Hengzhong Machinery, and Cangzhou Zhaoji Precision Machinery Co., Ltd. are known for their innovative designs and robust machinery.

- Zhangjiagang Dingsheng specializes in providing advanced equipment that integrates modern technology with traditional manufacturing techniques. They are known for their high production efficiency and customizable designs.

- Hengzhong Machinery focuses on producing machines that offer excellent performance with minimal downtime. Their commitment to quality and customer service has earned them a loyal client base.

- Cangzhou Zhaoji is recognized for its comprehensive range of forming machines. They emphasize R&D, constantly innovating to meet the evolving needs of the construction industry.

Factors to Consider When Choosing a Manufacturer

When selecting a Z purlin forming machine manufacturer, several factors should be evaluated

1. Reputation and Experience Look for manufacturers with a proven track record in the industry. Customer reviews and testimonials can provide insight into quality and reliability.

2. Technical Support and Warranty A manufacturer that offers robust technical support and a comprehensive warranty is preferable. This ensures that any operational issues can be promptly addressed, minimizing downtime.

3. Production Capacity Consider your production needs and choose a machine that can meet or exceed those requirements without compromising on quality.

4. Price vs. Value While budget considerations are important, focusing solely on cost can lead to long-term issues. Balance the initial investment against the value offered in terms of durability, efficiency, and support.

Conclusion

Z purlin forming machines play a pivotal role in the metal construction sector, significantly impacting production methods and efficiencies. As the demand for such equipment continues to grow, the importance of selecting the right manufacturer cannot be overstated. By considering factors like reputation, support, and customization abilities, businesses can ensure they invest in a machine that not only meets their current needs but also adapts to future challenges in the construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025