Cold Rolled Steel Channel Fabrication Using Advanced Roll Forming Technology

Cold Rolled Steel Channel Framing Roll Forming Machine A Comprehensive Overview

Cold rolled steel channel framing roll forming machines are essential tools in modern manufacturing, particularly in the construction and metalworking industries. These machines are designed to produce steel channels with precise dimensions and high structural integrity. In this article, we will explore the significance, working principles, benefits, and applications of cold rolled steel channel framing roll forming machines.

Understanding Cold Rolled Steel

Cold rolled steel (CRS) refers to steel that has been processed at room temperature, allowing for improved mechanical properties and enhanced surface finish. The process of cold rolling transforms the steel into thin, flat sheets or strips, which can then be formed into various shapes, including channels. Cold rolled steel is known for its strength, durability, and ability to maintain its shape across different loading conditions, making it a popular material for various construction applications.

What is a Roll Forming Machine?

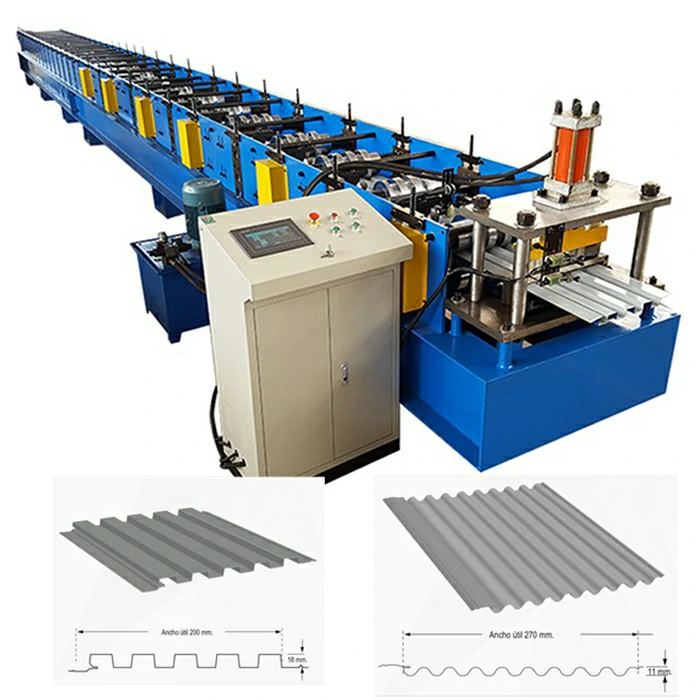

A roll forming machine is a continuous bending operation that involves passing a strip of metal through a series of rollers. These rollers gradually shape the metal into the desired profile, in this case, a channel. The incorporation of multiple sets of rollers allows manufacturers to achieve precise dimensions and consistent quality throughout the production process. The machinery can be custom designed to meet specific requirements, making it versatile for different sizes and types of channels.

The Working Principle

The operation of a cold rolled steel channel framing roll forming machine begins with a continuous coil of cold rolled steel. The coil is fed into the machine, where it passes through a series of rollers that shape the metal into a channel profile. As the metal passes through each roller set, it is subjected to controlled pressure and bending, gradually forming the desired channel shape.

The process can be adjusted in terms of speed, temperature, and pressure, allowing for the production of channels of varying thicknesses and sizes. Once formed, the channel can be cut to the desired length before being ejected. Advanced roll forming machines may also incorporate additional features such as automatic cutting, punching, and stacking, further enhancing productivity and efficiency.

Benefits of Roll Forming Machines

cold rolled steel channel framing roll forming machine

1. Precision and Accuracy Roll forming machines are designed to produce channels with exact dimensions, crucial for structural applications where integrity and fit are paramount.

2. High Production Rates These machines facilitate continuous production, allowing manufacturers to produce large volumes of channel framing in a relatively short amount of time.

3. Material Efficiency Unlike other manufacturing processes, roll forming minimizes material waste, making it a cost-effective option for producing shaped metal.

4. Versatility Roll forming machines can be easily customized to create a wide range of channel sizes and profiles, accommodating diverse industry needs.

5. Durability and Quality The cold rolling process enhances the strength of steel channels, providing better resistance to bending, warping, and other structural failures.

Applications of Cold Rolled Steel Channels

Cold rolled steel channels produced by roll forming machines have a wide range of applications across various industries. Some notable applications include

- Construction Steel channels are frequently used in building frameworks, providing support for structures such as walls, roofs, and floors. - Manufacturing In manufacturing, steel channels are employed in the creation of machinery, equipment frames, and conveyor systems. - Automotive Cold rolled steel channels serve as critical components in automotive manufacturing for vehicle frames and chassis. - HVAC Systems Channels are used in heating, ventilation, and air conditioning systems for lightweight framing and structural support.

Conclusion

Cold rolled steel channel framing roll forming machines play a pivotal role in the production of high-quality steel channels necessary for various industrial applications. The advantages of precision, efficiency, and durability make roll forming an indispensable process in today’s manufacturing landscape. As industries continue to evolve, the importance of these machines in delivering structural integrity and supporting innovative designs will remain paramount, ensuring that they stay at the forefront of metal fabricating technologies.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025