Jan . 30, 2025 06:29

Back to list

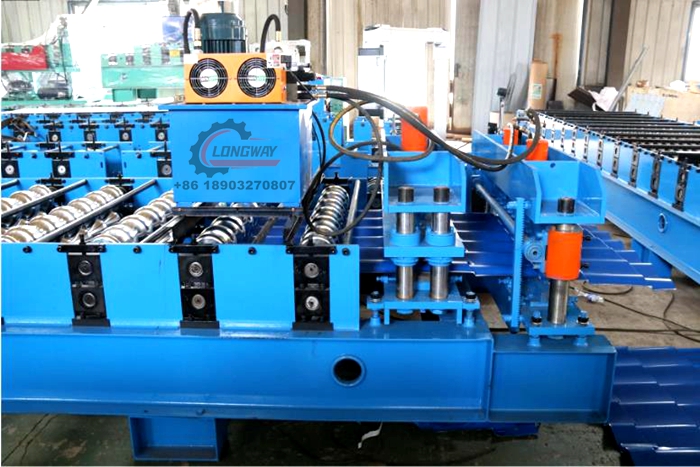

750 Trapezoidal Cladding wall panel forming machine

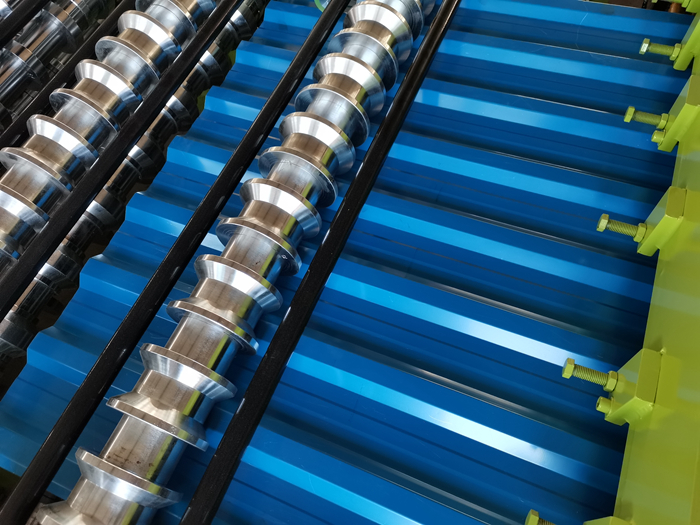

Wall panel roll forming machines have revolutionized the construction industry by providing efficient, cost-effective solutions for creating high-quality wall panels. These advanced machines embody the pinnacle of engineering and innovation, catering to the evolving needs of modern construction methodologies. Wall panel roll forming machines stand as crucial investments for companies seeking to optimize their production lines and improve overall output quality.

Trustworthiness is a critical factor that makes a particular wall panel roll forming machine manufacturer stand out. Companies that have established a reputation for reliability often offer extensive warranties and post-purchase support, underscoring their confidence in their products. This trust is built through years of delivering machines that not only meet but exceed customer expectations, safeguarding user investment and contributing to robust, enduring structures. Incorporating a wall panel roll forming machine into a production line signifies a commitment to quality and efficiency. These machines enable precise control over panel dimensions and profiles while allowing for scalability in production. Automated systems minimize material waste and labor costs, providing an excellent return on investment. Moreover, as environmental concerns become increasingly paramount, many machines are now designed to be energy-efficient and capable of forming panels from sustainable materials. In conclusion, wall panel roll forming machines represent a convergence of experience, expertise, authoritativeness, and trustworthiness. They are not just machines; they are essential tools for any entity serious about advancing in the construction sector. With their integration, businesses can enhance their construction capabilities, ensuring they stay ahead in a competitive landscape while providing top-notch quality that caters to the dynamic demands of modern-day infrastructure.

Trustworthiness is a critical factor that makes a particular wall panel roll forming machine manufacturer stand out. Companies that have established a reputation for reliability often offer extensive warranties and post-purchase support, underscoring their confidence in their products. This trust is built through years of delivering machines that not only meet but exceed customer expectations, safeguarding user investment and contributing to robust, enduring structures. Incorporating a wall panel roll forming machine into a production line signifies a commitment to quality and efficiency. These machines enable precise control over panel dimensions and profiles while allowing for scalability in production. Automated systems minimize material waste and labor costs, providing an excellent return on investment. Moreover, as environmental concerns become increasingly paramount, many machines are now designed to be energy-efficient and capable of forming panels from sustainable materials. In conclusion, wall panel roll forming machines represent a convergence of experience, expertise, authoritativeness, and trustworthiness. They are not just machines; they are essential tools for any entity serious about advancing in the construction sector. With their integration, businesses can enhance their construction capabilities, ensuring they stay ahead in a competitive landscape while providing top-notch quality that caters to the dynamic demands of modern-day infrastructure.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products