U Purlin Production Equipment for Efficient Metal Fabrication Solutions

The Evolution and Importance of U Purlin Making Machines

In the ever-evolving world of construction and manufacturing, efficiency and precision are paramount. One of the essential components in modern building frameworks is the U purlin, a cold-formed steel section that provides support and stability to roofs and walls. The manufacturing of U purlins has transitioned significantly over the years, thanks in large part to the advancement of U purlin making machines. These specialized machines play a crucial role in the construction industry, streamlining the production process and enhancing overall structural integrity.

Understanding U Purlins

U purlins are designed in a U shape, which provides exceptional load-bearing capabilities while minimizing material usage. They are versatile and can be found in a variety of applications, including warehouses, industrial buildings, and agricultural structures. The lightweight yet strong characteristics of U purlins make them a preferred choice for architects and engineers alike. However, the actual production of these steel sections requires precision engineering, which is where U purlin making machines come into play.

The Mechanics of U Purlin Making Machines

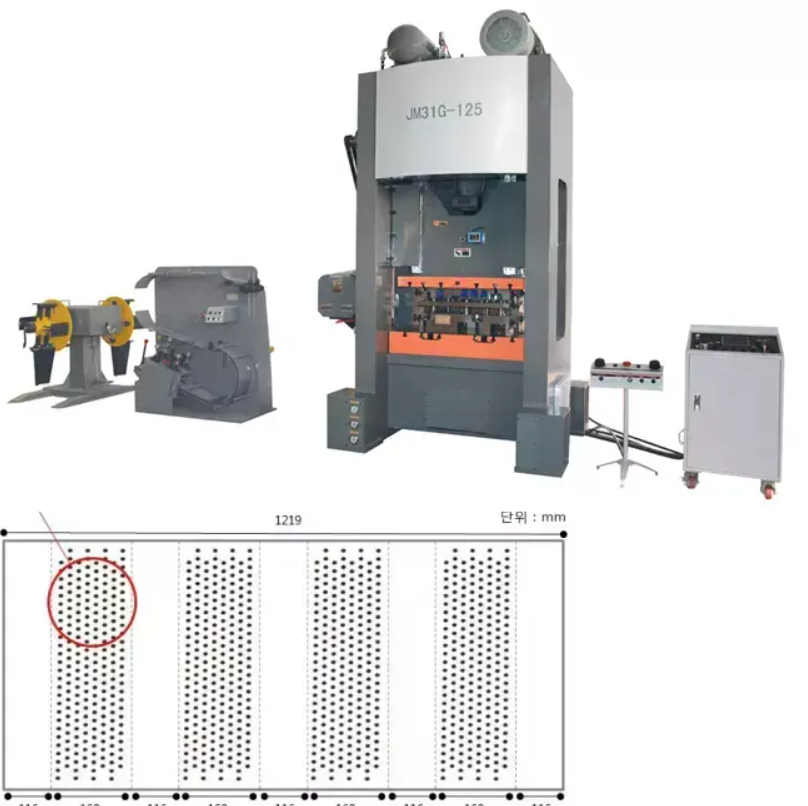

U purlin making machines are designed to produce U purlins efficiently and with high accuracy. The process typically involves the following steps uncoiling, leveling, cutting, and forming. These machines can handle steel coils of various gauges and dimensions, allowing for flexibility in production.

1. Uncoiling The steel coil is fed into the machine, where it is uncoiled and prepared for the next stage. 2. Leveling The uncoiled steel passes through a leveling system that ensures uniform thickness and straightness, crucial for maintaining the integrity of the final product. 3. Cutting After leveling, the steel is cut to the desired lengths, which can be programmed according to the specifications required by the customer.

u purlin making machine

4. Forming The cut steel sections then go through a series of rollers that gradually shape them into the U profile. This stage is critical, as it defines the mechanical properties of the purlin.

5. Finishing Finally, the formed U purlins are subjected to quality control checks and surface treatments, ensuring they meet industry standards.

Advantages of Using U Purlin Making Machines

Investing in U purlin making machines confers numerous advantages to manufacturers. First and foremost, these machines significantly increase production speed, allowing manufacturers to meet high demands without compromising quality. The precision of these machines reduces waste material, which translates to cost savings in the long run.

Moreover, modern U purlin making machines can be automated and integrated with advanced software systems. This increases operational efficiency and minimizes human error. Additionally, manufacturers can easily adjust specifications to produce custom sizes and shapes, catering to specific project requirements.

Conclusion

The U purlin making machine is a vital asset in the construction and manufacturing sectors. It not only improves production efficiency but also ensures the consistent quality of U purlins, which are essential for the stability and safety of structures. As construction projects grow in complexity and demand for high-strength materials continues to rise, the role of U purlin making machines will undoubtedly become even more significant. Embracing these technological advancements is key to staying competitive in an ever-changing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025