Efficient Metal Roofing Sheet Bending Equipment for Precision Design and Construction

Metal Roof Sheet Bending Machines An Essential Tool for Roofing Professionals

In the roofing industry, precision and durability are paramount. Metal roof sheet bending machines have become essential tools for professionals seeking to produce high-quality roofing materials. These machines enable users to create custom metal sheets tailored to various architectural designs and requirements, ensuring both aesthetic appeal and structural integrity.

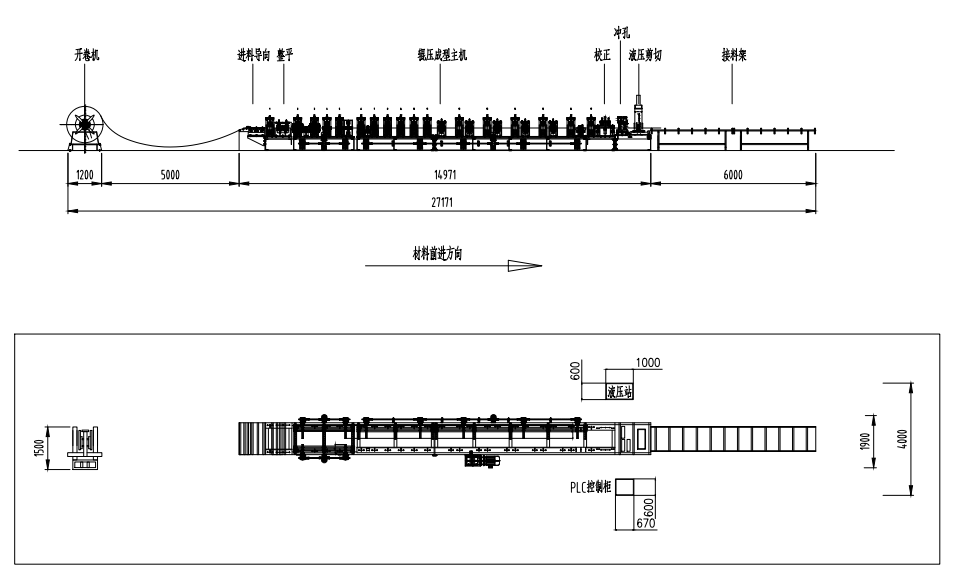

A metal roof sheet bending machine is specifically designed to manipulate the shape of metal roofing sheets. It uses advanced technology, such as hydraulic or electric systems, to accurately bend metal sheets into desired angles and profiles. This capability is crucial for creating overlaps and connections necessary for effective water drainage and wind resistance in roofing applications.

One significant advantage of using a bending machine is the efficiency it brings to roofing projects. Traditionally, bending metal required manual labor and careful measurements, increasing the chance of errors and wastage. With a dedicated bending machine, roofing professionals can achieve consistent results in a fraction of the time. This efficiency not only speeds up the workflow but also reduces the overall costs associated with labor and material waste.

metal roof sheet bending machine

Moreover, modern metal roof sheet bending machines offer versatility

. They can handle a variety of materials, including steel, aluminum, and copper, allowing contractors to work with whatever material best suits their project's needs. The machines can also accommodate different thicknesses, making them suitable for both residential and commercial roofing applications.In addition to their practical benefits, metal roof sheet bending machines also contribute to the environmental sustainability of roofing practices. By enabling precise cuts and bends, these machines help minimize scrap metal, resulting in less waste. This aligns with the growing trend in the construction industry towards more sustainable practices, appealing to eco-conscious consumers.

Maintenance is another crucial aspect of investing in a metal roof sheet bending machine. Regular servicing ensures the machine operates at peak performance, prolonging its lifespan and enhancing its efficiency. Users should follow manufacturer guidelines for upkeep, including lubrication, inspections, and timely repairs.

In conclusion, metal roof sheet bending machines are indispensable in today’s roofing industry. They provide speed, precision, and flexibility, making them a worthy investment for any roofing contractor. As demand for metal roofing continues to grow, the importance of having reliable bending machinery will only increase, thus shaping the future of roofing craftsmanship.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025