Exploring Different Types of Roll Forming Machines for Various Industries

Types of Roll Forming Machine Companies

Roll forming machines are essential in various industries, allowing for the production of metal sheets and profiles through a continuous bending process. These machines are widely utilized in the automotive, construction, and HVAC sectors, among others. Given the increased demand for rolled products, numerous companies specializing in roll forming machinery have emerged. This article explores the types of roll forming machine companies and their unique offerings.

1. Manufacturers of Standard Roll Forming Machines

Many companies focus on designing and manufacturing standard roll forming machines. These machines are designed to produce specific profiles at a consistent speed and quality. They typically offer a range of standard shapes and sizes, catering to industries requiring general-purpose applications. Firms specializing in standard machines often stock common roll tooling and are preferred by businesses looking for quick turnaround times without the need for custom designs.

2. Custom Roll Forming Machine Companies

In contrast to companies that produce standard machines, custom roll forming machine manufacturers focus on tailored solutions. They work closely with clients to understand the specific requirements of their projects, including unique shapes, sizes, and materials. This customization often involves creating bespoke tooling and dies. These companies are particularly valuable for industries that require specialized profiles, such as architectural firms looking for distinct metal shapes or automotive manufacturers seeking complex components. Due to the intricacies involved in custom projects, these companies usually have a more extended design and manufacturing timeline.

3. Hybrid Roll Forming Machine Producers

With technological advancements, some companies have started producing hybrid roll forming machines. These machines combine traditional roll forming techniques with advanced features such as automation and digital controls. They provide enhanced efficiency and flexibility in production, allowing manufacturers to switch between different profiles without extensive downtime. Hybrid machines are particularly appealing to companies looking to increase production capacity while reducing labor costs, making them a popular choice in the competitive manufacturing landscape.

types of roll forming machine companies

4. Niche Roll Forming Equipment Suppliers

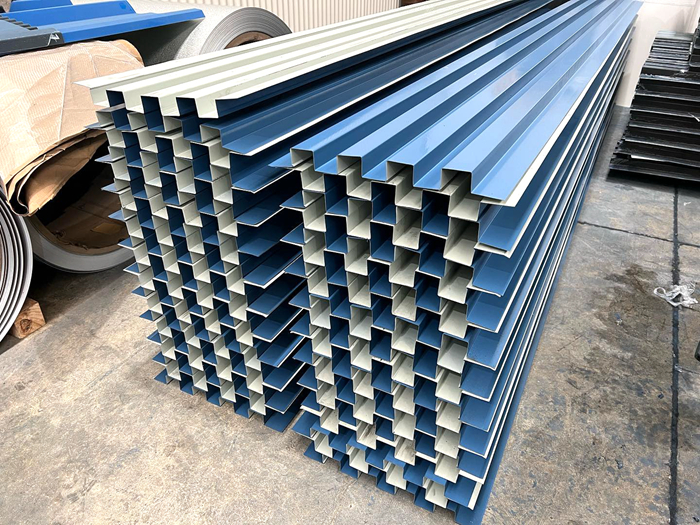

Some companies specialize in niche applications, crafting roll forming machines for specific sectors or products. This includes manufacturers that focus on creating roll forming equipment for roofing panels, metal framing, or intricate fencing designs. These niche suppliers have deep expertise in their respective markets, allowing them to develop machinery that meets the exacting standards of specialized industries. Their products are typically characterized by innovation, allowing clients to differentiate themselves in the market.

5. Global and Local Roll Forming Machine Companies

The roll forming machine industry is characterized by both global players and local manufacturers. Global companies often have extensive resources and a wide array of machinery, catering to diverse markets worldwide. In contrast, local companies can offer personalized service and a better understanding of regional market needs. Choosing between a global supplier and a local manufacturer often depends on the customer’s requirements, such as budget limitations, delivery timelines, and the need for local support.

6. Service and Maintenance Providers

Finally, some companies specialize in the service and maintenance of roll forming machines. They offer essential support to manufacturers by ensuring that their equipment operates efficiently and effectively. These companies provide a range of services, including routine maintenance, repairs, and retrofitting outdated machines with modern technology. This aspect of the industry is crucial because it ensures that manufacturers can maximize their production capabilities and minimize downtime.

In conclusion, the roll forming machine industry is diverse, featuring various companies that cater to different needs and sectors. From standard machine manufacturers to custom solutions, hybrid producers, niche suppliers, global players, and dedicated service providers, the landscape is rich with options. As industries continue to evolve, the demand for innovative and efficient roll forming machines will likely lead to even more specialization within this vibrant marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025