Drip Edge Machine Manufacturing Efficiency and Innovation in Production Solutions

Drip Edge Machine Factories Revolutionizing Roofing and Construction

In the ever-evolving landscape of construction and roofing, efficiency and precision play a crucial role in ensuring durable and high-quality buildings. Among the various innovations that have emerged over the years, drip edge machines stand out as transformative tools that streamline the manufacturing process of roofing materials. These specialized machines, designed for producing drip edges, have become essential in many roofing operations, and numerous factories are now dedicated to their production.

Drip edges are metal flashings installed at the edges of roofs to direct water away from the fascia and prevent water damage to the underlying structure. They play a vital role in maintaining the integrity of a roofing system and are often required by building codes. The introduction of drip edge machines in factories not only improves the quality of these flashings but also enhances production efficiency, providing a significant advantage to manufacturers.

The Mechanisms of Drip Edge Machines

A typical drip edge machine operates through a series of bending and forming processes that shape metal sheets into the desired profile. These machines are equipped with advanced technology, including computerized controls that allow for precise adjustments based on design specifications. Operators can easily switch between different designs or sizes, catering to various client needs without significant downtime. This flexibility is crucial in an industry where customization is often required.

The materials used in drip edge production are typically aluminum or galvanized steel due to their durability and resistance to corrosion. Drip edge machines are capable of handling various thicknesses and widths, allowing manufacturers to produce a wide range of products. This adaptability not only meets specific project requirements but also enables suppliers to serve a broader market segment.

The Impact on Manufacturing Efficiency

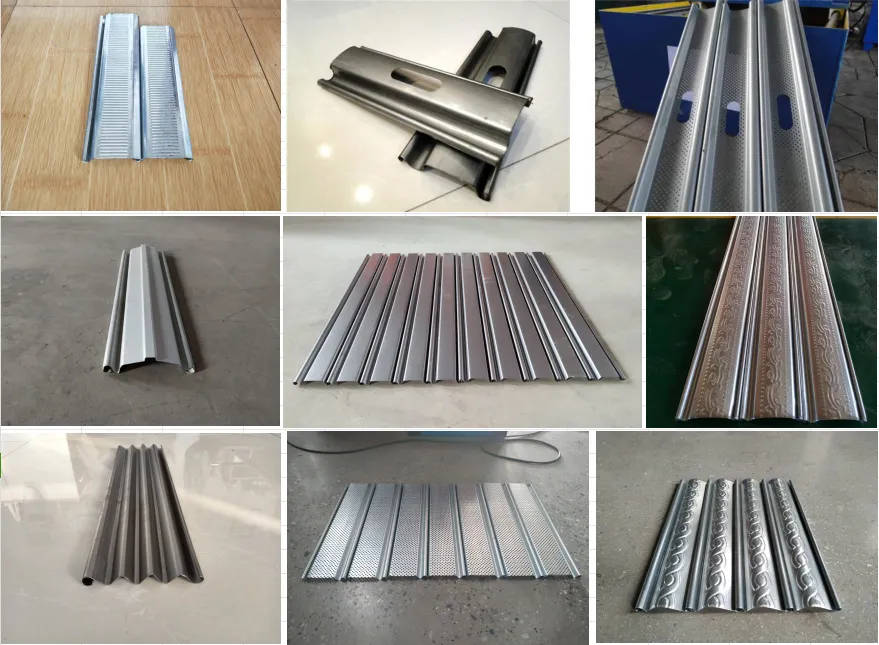

drip edge machine factories

The introduction of drip edge machines in factories has had a profound impact on manufacturing efficiency. Traditional methods of producing drip edges were often labor-intensive and time-consuming, resulting in higher production costs and longer lead times. However, with automated machines, factories can significantly reduce labor requirements and produce consistent, high-quality components more quickly.

This efficiency is not just about speed; it also translates to better resource management. With precise cutting and forming capabilities, there is minimal waste of raw materials. Factories can optimize their operations, reducing costs and lowering their environmental footprint. The ability to produce drip edges in-house also allows roofing contractors to have greater control over their supply chain, leading to increased reliability and satisfaction among customers.

The Future of Drip Edge Machine Factories

As technology continues to advance, the future of drip edge machine factories looks promising. The integration of smart technology, such as IoT (Internet of Things) devices and AI (Artificial Intelligence), has the potential to revolutionize production processes further. Factories could implement predictive maintenance strategies, monitor production quality in real time, and even automate entire production lines.

Moreover, as sustainability becomes a fundamental value in construction, manufacturers are likely to adapt their practices to incorporate greener technologies. Innovations in materials and processes could lead to even more eco-friendly drip edge solutions, benefiting both the industry and the environment.

In conclusion, drip edge machine factories represent a significant leap forward in roofing manufacturing. By embracing automation and innovative technologies, these factories not only improve efficiency and product quality but also empower contractors and builders to deliver superior roofing solutions. As the industry continues to evolve, the role of drip edge machines will undoubtedly become even more critical in shaping the future of construction. With a commitment to excellence and adaptability, drip edge machine factories are poised to lead the way in the roofing industry's next chapter.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025