Three-Segment Corrugated Roll Forming Equipment for Efficient Sheet Production

Three-Layer Corrugated Roll Forming Machine Revolutionizing the Packaging Industry

In the ever-evolving world of manufacturing and packaging, efficiency and sustainability are paramount. Among the innovative technologies that contribute to these goals is the three-layer corrugated roll forming machine. This sophisticated equipment has transformed how corrugated materials are produced, offering a range of benefits that cater to the demands of modern industries.

Understanding the Three-Layer Corrugated Roll Forming Machine

At its core, the three-layer corrugated roll forming machine is designed to produce corrugated sheets made from multiple layers of paper. Typically, these machines operate on the principle of continuous production, where paper rolls are fed into the machine, and their transformation into corrugated sheets occurs seamlessly. The three-layer aspect refers to the machine's capability to combine three distinct layers of material, usually consisting of two flat liners and a fluted inner layer.

This configuration offers enhanced strength, durability, and insulation properties, making the resulting corrugated sheets ideal for various applications, including packaging, construction, and even furniture manufacturing.

Key Components of the Machine

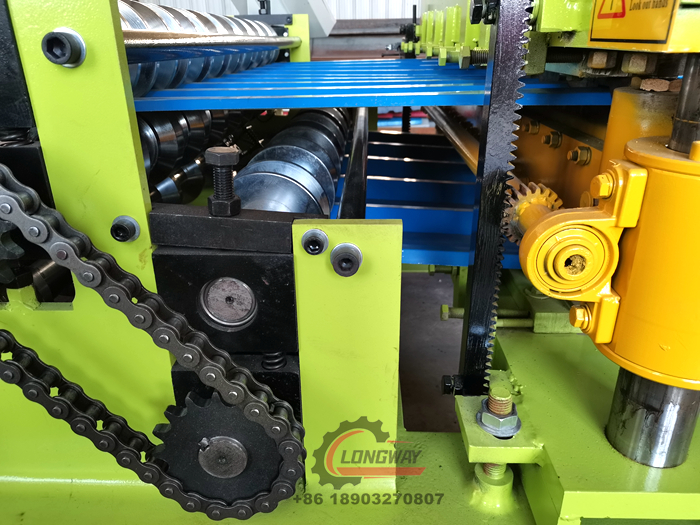

Understanding the components of a three-layer corrugated roll forming machine is crucial in appreciating its functionality. The main parts include

1. Feeding Section This is where raw paper rolls are fed into the machine. The paper is often pre-treated to enhance its bonding capabilities when layers are combined.

2. Heating System To ensure proper adhesion between the layers, a heating system is employed. It typically utilizes steam or hot air to soften the glues applied to the paper.

3. Corrugating Roller This is the heart of the machine, where the paper is shaped into flutes. The design and arrangement of these rollers significantly impact the final product's strength and flexibility.

three layer corrugated roll forming machine

5. Cutting System The machine incorporates a cutting system to slice the continuous sheet into desired lengths for easy handling and transportation.

6. Control System Modern machines come with sophisticated control systems, often computerized, allowing for precise adjustments in pressure, temperature, and cutting, enhancing overall efficiency.

Benefits of Using a Three-Layer Corrugated Roll Forming Machine

1. Increased Efficiency The ability to produce corrugated sheets continuously reduces production time significantly. Manufacturers can meet high-volume demands without compromising quality, making this technology ideal for large-scale operations.

2. Cost-Effectiveness By optimizing the use of raw materials and reducing waste, companies can lower production costs. Additionally, the durability of three-layer corrugated products often translates into lower shipping costs due to reduced damage during transit.

3. Eco-Friendly Characteristics With growing concerns about environmental sustainability, the three-layer corrugated roll forming machine promotes eco-friendly practices. Corrugated materials are primarily made from recycled paper, and their recyclability at the end of their lifecycle further supports sustainability.

4. Versatility The machine can produce sheets in various sizes and strengths, catering to diverse industry needs. Whether for food packaging, electronics, or construction materials, these machines can adapt to specific requirements.

5. Improved Quality The consistent production process ensures that the corrugated sheets maintain high-quality standards, reducing the likelihood of defects and ensuring customer satisfaction.

Conclusion

The three-layer corrugated roll forming machine represents a significant advancement in manufacturing technology within the packaging industry. Its ability to produce strong, durable, and eco-friendly packaging solutions efficiently aligns with contemporary demands for sustainability and performance. As industries continue to seek innovative ways to enhance production processes, the adoption of such machines is set to grow, ultimately contributing to a more efficient and environmentally responsible future. With its myriad benefits, the three-layer corrugated roll forming machine is not just a tool for production; it is a catalyst for change in the packaging landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025