Affordable False Ceiling Channel Production Equipment from Reliable Manufacturers

Exploring the Market for False Ceiling Channel Making Machines

In today’s construction and interiors sector, false ceilings have gained immense popularity for their aesthetic appeal and functional benefits, such as improved acoustics and energy efficiency. As the demand for false ceilings continues to rise, so does the need for efficient manufacturing solutions. One key player in this sector is the false ceiling channel making machine, which plays a pivotal role in the production of various ceiling frameworks. In this article, we will delve into the market dynamics concerning false ceiling channel making machines, including their prices and factory considerations.

Understanding False Ceiling Channel Making Machines

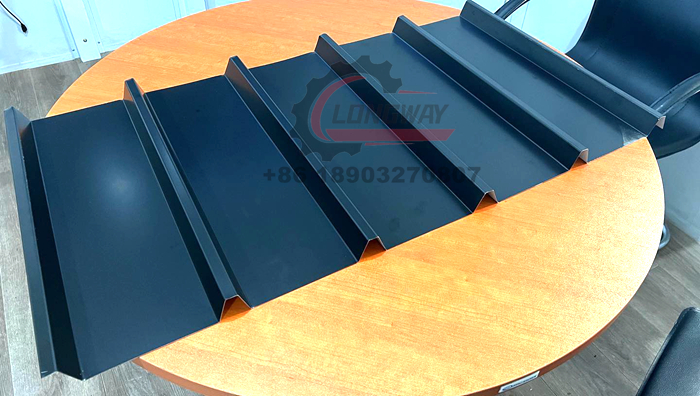

False ceiling channel making machines are specialized pieces of equipment designed to manufacture the metal channels and frames that support false ceilings. These machines can produce a variety of profiles and sizes, catering to different design requirements. The versatility and efficiency of these machines have made them indispensable in the modular construction industry.

Manufacturers often use materials such as galvanized steel or aluminum to create lightweight and durable channels. The machine processes include cutting, bending, and forming metal sheets into the required shapes, ensuring high precision and quality. This automation significantly reduces labor costs and time, making it an attractive investment for businesses in the construction sector.

Market Trends and Demand

The global market for false ceiling systems has been driven by rapid urbanization, increased construction activities, and a growing emphasis on innovative design solutions. As more architects and interior designers incorporate false ceilings into their projects, the demand for reliable channel making machines has surged. Additionally, factors like the growth of the real estate sector, both residential and commercial, further fuel this demand.

Moreover, as architectural trends evolve, there's an increased need for custom designs and unique ceiling structures. This trend propels the requirement for advanced machines that can easily adapt to new specifications, enhancing flexibility in production. In response, manufacturers of channel making machines are innovating to keep pace with these evolving market demands, continually improving efficiency and product quality.

Pricing Factors

false ceiling channel making machine price factory

The price of false ceiling channel making machines can vary significantly based on various factors. These include the machine’s specifications, automation level, production capacity, and manufacturer reputation. Generally, prices can range from a few thousand to several tens of thousands of dollars.

For example, a basic manual machine suitable for small-scale operations may cost anywhere from $5,000 to $15,000, while fully automated systems designed for large-scale production can range from $20,000 to over $100,000. Additionally, machines that offer specialized features, like programmable controls and advanced safety systems, may come at a premium price.

Beyond initial costs, potential buyers must also consider maintenance expenses, spare parts availability, and after-sales service when evaluating machine prices. A machine with a higher upfront cost may provide better long-term savings if it requires less frequent repairs and boasts efficient operation.

Selecting a Reliable Factory

When looking to purchase a false ceiling channel making machine, choosing the right factory is crucial. Prospective buyers should prioritize manufacturers with a solid reputation for quality and reliability. Comprehensive research into the factory's track record, customer feedback, and product warranty policies can aid in making an informed decision.

Furthermore, potential buyers should inquire about the level of support offered by the factory, including after-sales service and technical assistance. Effective training programs for machine operation and maintenance can significantly enhance productivity and machine lifespan.

Conclusion

The market for false ceiling channel making machines is poised for growth as the demand for innovative and practical interior solutions continues to increase. With a careful assessment of market trends, pricing strategies, and factory reliability, businesses can make informed decisions to invest in the right machinery that meets their production needs. Investing in advanced manufacturing equipment not only enhances operational efficiency but also positions companies to capitalize on the burgeoning opportunities within the construction industry. As craftsmanship meets technology in the field of modular interiors, false ceiling channel making machines will undoubtedly be at the forefront of this evolution.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025