Jan . 31, 2025 05:40

Back to list

Maquina para fabricar paneles de techo 910 PV6

Navigating the complex world of construction and manufacturing often requires tools that blend efficiency with innovation. The steel roof making machine stands as a pivotal element in this intricate landscape, transforming how steel roofing solutions are engineered and implemented. With decades of industry evolution, these machines have become synonymous with durability, performance, and precision.

Trustworthiness is paramount in any industry, especially when dealing with heavy machinery like steel roof making machines. Trust is built through transparency in the manufacturing process, offering warranties and reliable after-sales services. An investment in a steel roof making machine is substantial; thus, it is crucial for manufacturers to provide comprehensive support, ranging from installation guidance to technical assistance. Companies that offer extensive support mechanisms and maintain open channels of communication with clients tend to foster long-lasting relationships that are mutually beneficial. The strategic acquisition of a high-quality steel roof making machine thus emerges as a cornerstone for businesses aiming to enhance their roofing project capabilities. By reducing manual labor and accelerating production timelines, these machines not only improve operational efficiency but also help in minimizing production costs. Plus, they allow businesses to stay competitive in a market that continually demands precision and customization. Choosing the right machine involves assessing factors such as production capacity, the material thickness it can handle, and the type of profiles it can create. It's essential to work with a reputable supplier who can provide comprehensive service and parts support post-purchase. This ensures that the machine remains a valuable asset over many years, adapting to both current and future production demands. In conclusion, steel roof making machines are more than just pieces of equipment—they are enablers of architectural innovation and efficiency. Their evolution continues to empower the construction industry with the capabilities needed to meet the robust demands of modern-day building, enabling projects that are not only sturdy and reliable but also economically and environmentally viable. Such machines are indispensable to any construction company serious about achieving excellence in steel roofing.

Trustworthiness is paramount in any industry, especially when dealing with heavy machinery like steel roof making machines. Trust is built through transparency in the manufacturing process, offering warranties and reliable after-sales services. An investment in a steel roof making machine is substantial; thus, it is crucial for manufacturers to provide comprehensive support, ranging from installation guidance to technical assistance. Companies that offer extensive support mechanisms and maintain open channels of communication with clients tend to foster long-lasting relationships that are mutually beneficial. The strategic acquisition of a high-quality steel roof making machine thus emerges as a cornerstone for businesses aiming to enhance their roofing project capabilities. By reducing manual labor and accelerating production timelines, these machines not only improve operational efficiency but also help in minimizing production costs. Plus, they allow businesses to stay competitive in a market that continually demands precision and customization. Choosing the right machine involves assessing factors such as production capacity, the material thickness it can handle, and the type of profiles it can create. It's essential to work with a reputable supplier who can provide comprehensive service and parts support post-purchase. This ensures that the machine remains a valuable asset over many years, adapting to both current and future production demands. In conclusion, steel roof making machines are more than just pieces of equipment—they are enablers of architectural innovation and efficiency. Their evolution continues to empower the construction industry with the capabilities needed to meet the robust demands of modern-day building, enabling projects that are not only sturdy and reliable but also economically and environmentally viable. Such machines are indispensable to any construction company serious about achieving excellence in steel roofing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

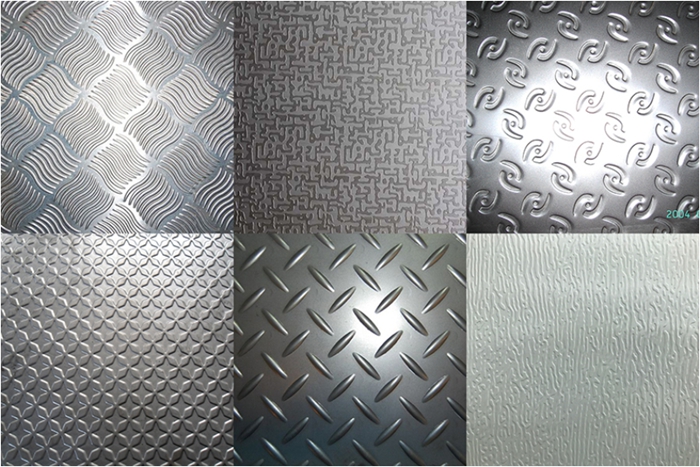

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products