Feb . 01, 2025 05:59

Back to list

Metal sheet Perforados punching machine

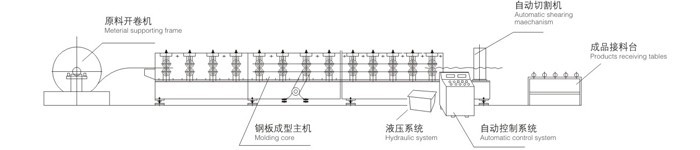

Standing seam rolling machines have revolutionized the roofing industry, providing an efficient solution that enhances both the aesthetics and durability of modern structures. For the uninitiated, these machines are pivotal in shaping metal panels that interlock seamlessly, thereby constructing robust and weather-resistant roofs. Delving into the intricacies of these machines reveals their unparalleled prowess in elevating construction standards.

Authoritativeness in the use of standing seam rolling machines is established by the endorsement from construction and architectural experts who advocate for their inclusion in modern designs. Notably, their capacity to accommodate expansive spans without compromising structural integrity aligns them with contemporary architectural trends that favor open, airy spaces. Furthermore, industry standards affirm that the interlocking nature of standing seam roofs effectively reduces leak risks, reinforcing the paradigm of roofs as the first defense in building envelopes. Trustworthiness of these machines is further evidenced by their compliance with international safety and quality standards. Reliable manufacturers ensure that every component from the die to the control system meets stringent benchmarks for performance and longevity. Moreover, ongoing innovations focus on optimizing power consumption and reducing operational footprint, echoing the global shift towards eco-friendly construction practices. In conclusion, the standing seam rolling machine embodies a blend of engineering prowess and practical utility, setting a gold standard for roofing solutions. Its role extends beyond mere panel fabrication; it is instrumental in shaping a future where buildings are durable, visually appealing, and environmentally conscious. For industry professionals seeking a reliable roofing method, this machinery stands out as a testament to progress and reliability in the construction realm, offering peace of mind and superior protection for years to come.

Authoritativeness in the use of standing seam rolling machines is established by the endorsement from construction and architectural experts who advocate for their inclusion in modern designs. Notably, their capacity to accommodate expansive spans without compromising structural integrity aligns them with contemporary architectural trends that favor open, airy spaces. Furthermore, industry standards affirm that the interlocking nature of standing seam roofs effectively reduces leak risks, reinforcing the paradigm of roofs as the first defense in building envelopes. Trustworthiness of these machines is further evidenced by their compliance with international safety and quality standards. Reliable manufacturers ensure that every component from the die to the control system meets stringent benchmarks for performance and longevity. Moreover, ongoing innovations focus on optimizing power consumption and reducing operational footprint, echoing the global shift towards eco-friendly construction practices. In conclusion, the standing seam rolling machine embodies a blend of engineering prowess and practical utility, setting a gold standard for roofing solutions. Its role extends beyond mere panel fabrication; it is instrumental in shaping a future where buildings are durable, visually appealing, and environmentally conscious. For industry professionals seeking a reliable roofing method, this machinery stands out as a testament to progress and reliability in the construction realm, offering peace of mind and superior protection for years to come.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products