Jan . 29, 2025 01:34

Back to list

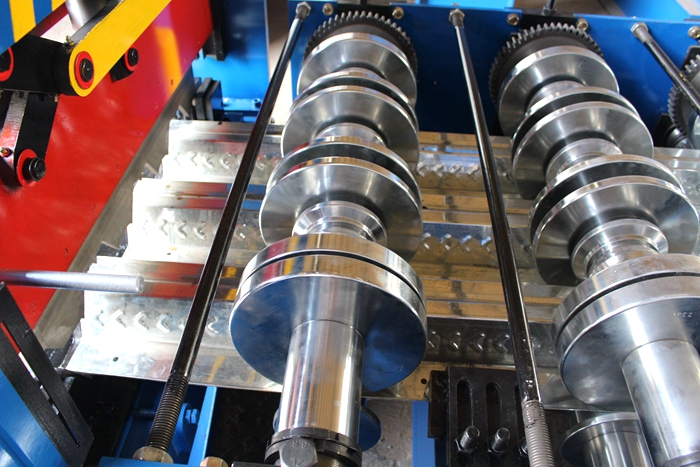

standing seam profiling machine

The evolution of roofing technologies has significantly altered the landscape of building construction, where efficiency and reliability are now non-negotiable. The standing seam profiling machine represents a pivotal advancement in the roofing industry, offering various benefits that cater to both contractors and clients alike.

Safety is another domain where these machines shine. The automated nature of the panel-producing process reduces the need for extensive manual labor at heights, consequently decreasing potential accidents on construction sites. The machines are designed with user-friendly interfaces that further ensure operators can manage them efficiently with minimal risk. The authority and trustworthiness of standing seam profiling machines are extensively documented through industry certifications and real-world applications. Leading manufacturers provide comprehensive training and support to users, offering a systematic understanding of machine operations and maintenance. Builders who invest in these machines generally gain access to a wealth of resources such as technical expertise, service warranties, and robust spare parts availability, which all contribute to the reliability and reputation of these complex tools. Experts in the field consistently emphasize how these machines help maintain stringent quality controls. The automated processes reduce human error, ensuring uniformity across all produced panels — a factor that is crucial for maintaining standards in large-scale commercial projects or bespoke architectural undertakings. Building professionals applaud the high return on investment these machines offer. The initial investment is quickly offset by the cost savings from reduced labor, minimized waste, and lower long-term maintenance requirements. They serve as a testament to how technology can empower industries to move towards more sustainable and economically viable practices. Testimonials from roofing professionals who have integrated standing seam profiling machines into their operations praise their unrivaled efficiency and precision. These machines have translated into improved client satisfaction, stronger business reputation, and favorable market positioning in a competitive industry. Clients who opt for roofs installed with these machines not only enjoy superior durability and aesthetics but also contribute to sustainable building practices. In conclusion, standing seam profiling machines exemplify the pinnacle of roofing technology. They're not just another tool; they're an investment in quality, efficiency, and sustainability. As industries continue to evolve, machines like these will spearhead innovation, setting higher benchmarks for what can be achieved in construction. They embody the expertise and experience needed to craft structures that stand the test of time — making their value to the modern builder undeniable.

Safety is another domain where these machines shine. The automated nature of the panel-producing process reduces the need for extensive manual labor at heights, consequently decreasing potential accidents on construction sites. The machines are designed with user-friendly interfaces that further ensure operators can manage them efficiently with minimal risk. The authority and trustworthiness of standing seam profiling machines are extensively documented through industry certifications and real-world applications. Leading manufacturers provide comprehensive training and support to users, offering a systematic understanding of machine operations and maintenance. Builders who invest in these machines generally gain access to a wealth of resources such as technical expertise, service warranties, and robust spare parts availability, which all contribute to the reliability and reputation of these complex tools. Experts in the field consistently emphasize how these machines help maintain stringent quality controls. The automated processes reduce human error, ensuring uniformity across all produced panels — a factor that is crucial for maintaining standards in large-scale commercial projects or bespoke architectural undertakings. Building professionals applaud the high return on investment these machines offer. The initial investment is quickly offset by the cost savings from reduced labor, minimized waste, and lower long-term maintenance requirements. They serve as a testament to how technology can empower industries to move towards more sustainable and economically viable practices. Testimonials from roofing professionals who have integrated standing seam profiling machines into their operations praise their unrivaled efficiency and precision. These machines have translated into improved client satisfaction, stronger business reputation, and favorable market positioning in a competitive industry. Clients who opt for roofs installed with these machines not only enjoy superior durability and aesthetics but also contribute to sustainable building practices. In conclusion, standing seam profiling machines exemplify the pinnacle of roofing technology. They're not just another tool; they're an investment in quality, efficiency, and sustainability. As industries continue to evolve, machines like these will spearhead innovation, setting higher benchmarks for what can be achieved in construction. They embody the expertise and experience needed to craft structures that stand the test of time — making their value to the modern builder undeniable.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products