Jan . 19, 2025 05:50

Back to list

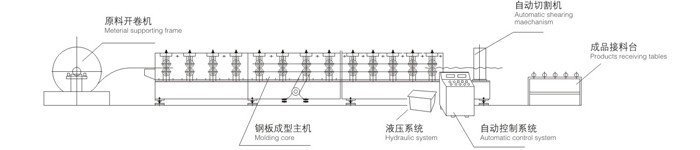

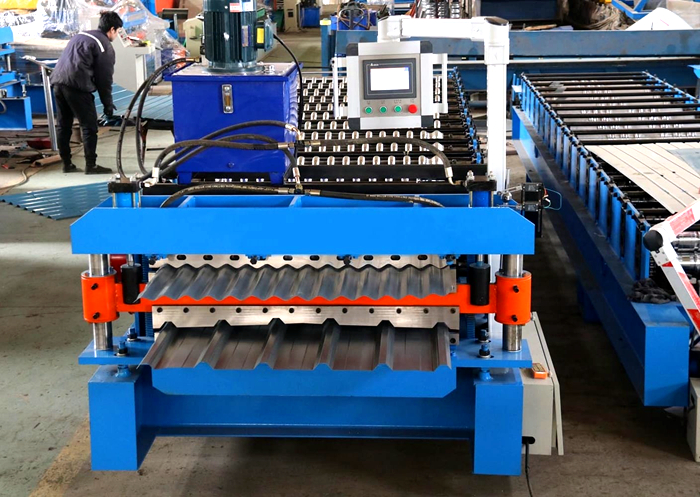

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

Standing seam panel machines have become game-changers in the roofing industry, providing exceptional efficiency and reliability for contractors and businesses aiming to enhance their productivity. These machines, renowned for their precision and durability, offer several compelling advantages, making them indispensable in any roofing project. Having delved deeply into the capabilities and functionalities of these machines, this analysis unearths why they stand out in a competitive market.

Trustworthiness is inherent in leading standing seam panel machines due to rigorous testing and quality assurance protocols in their manufacturing process. Top manufacturers stand by their products, often offering extended warranties and comprehensive customer service support. This commitment to customer satisfaction inherently builds trust, as buyers know they are investing in a reliable and supported machine. Expertise in metal roof installations highlights the environmental benefits of using standing seam panels. They reflect sunlight efficiently, reducing the energy needed for temperature regulation within a building. Roofing contractors who employ standing seam panel machines can thus provide additional value to environmentally conscious clients seeking sustainable building solutions. Beyond environmental benefits, the technological advancements in these machines also recommend them for large-scale commercial projects. The ability of high-tech models to interface with software for precise digital measurements and cutting underlines their place in advanced roofing system installations. Expertise in handling these machines further optimizes the roofing process, ensuring efficient use of materials and resources. The authority of standing seam panel machines in the realm of roofing is well-established, with manufacturers often leading the industry due to years of innovation and development. Many machines on the market today reflect decades of cumulative knowledge, persistent research, and user feedback integration, reinforcing their authority and offering assurance to new adopters of their technology. In conclusion, standing seam panel machines are indispensable assets in modern roofing, perfectly balancing customization, durability, environmental stewardship, and technological innovation. They enhance the reliability and effectiveness of metal roofing projects, providing tangible benefits that resonate with contractors, architects, and property owners alike. In a competitive market, these machines represent a convergence of tradition and innovation, expertly crafted to meet contemporary roofing demands with utmost authority and trust.

Trustworthiness is inherent in leading standing seam panel machines due to rigorous testing and quality assurance protocols in their manufacturing process. Top manufacturers stand by their products, often offering extended warranties and comprehensive customer service support. This commitment to customer satisfaction inherently builds trust, as buyers know they are investing in a reliable and supported machine. Expertise in metal roof installations highlights the environmental benefits of using standing seam panels. They reflect sunlight efficiently, reducing the energy needed for temperature regulation within a building. Roofing contractors who employ standing seam panel machines can thus provide additional value to environmentally conscious clients seeking sustainable building solutions. Beyond environmental benefits, the technological advancements in these machines also recommend them for large-scale commercial projects. The ability of high-tech models to interface with software for precise digital measurements and cutting underlines their place in advanced roofing system installations. Expertise in handling these machines further optimizes the roofing process, ensuring efficient use of materials and resources. The authority of standing seam panel machines in the realm of roofing is well-established, with manufacturers often leading the industry due to years of innovation and development. Many machines on the market today reflect decades of cumulative knowledge, persistent research, and user feedback integration, reinforcing their authority and offering assurance to new adopters of their technology. In conclusion, standing seam panel machines are indispensable assets in modern roofing, perfectly balancing customization, durability, environmental stewardship, and technological innovation. They enhance the reliability and effectiveness of metal roofing projects, providing tangible benefits that resonate with contractors, architects, and property owners alike. In a competitive market, these machines represent a convergence of tradition and innovation, expertly crafted to meet contemporary roofing demands with utmost authority and trust.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products