Soffit Roll Forming Machines Manufacturers for High-Quality Building Component Production and Efficient Solutions

Soffit Roll Forming Machine Factories An Overview

In the modern manufacturing landscape, efficiency and precision are paramount. Among the various techniques employed, roll forming has emerged as a highly effective method for producing metal components, particularly soffits. Soffit roll forming machines play a critical role in creating these essential building materials, which are used to cover the underside of roof overhangs, eaves, and other architectural features.

Understanding Soffit Roll Forming Machines

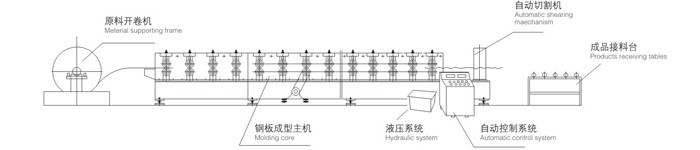

Soffit roll forming machines are specialized equipment designed to convert metal coils into soffit panels through a series of bending and shaping processes. These machines use a continuous roll forming method, which involves feeding a metal strip through a series of rollers that gradually shape it into the desired profile. The end product is a lightweight, durable, and aesthetically pleasing panel that is ready for installation.

The primary materials used in the production of soffits are aluminum and galvanized steel, both of which offer excellent resistance to corrosion. This is particularly important for soffits, as they are often exposed to the elements. The precision and consistency achieved by roll forming make these machines ideal for producing soffit panels that meet industry standards and customer specifications.

Key Features of Soffit Roll Forming Machines

1. Customizable Profiles One of the significant advantages of soffit roll forming machines is their ability to produce a wide range of panel profiles. Factories can customize the design according to the specific requirements of a project, which is a considerable advantage over traditional manufacturing methods.

2. High Production Efficiency Roll forming machines are designed for continuous operation, which significantly increases production rates. A well-configured machine can produce thousands of linear feet of soffit panels in a day, ensuring that manufacturers can meet high demand without compromising on quality.

soffit roll forming machine factories

3. Minimal Material Wastage The roll forming process is inherently efficient, leading to minimal waste of raw materials. By utilizing metal coils effectively, manufacturers can lower production costs and reduce their environmental footprint.

4. Precision Engineering The advanced engineering of soffit roll forming machines ensures that each panel is produced with high levels of accuracy. This is crucial for applications where exact dimensions are necessary for proper installation.

The Role of Soffit Roll Forming Machine Factories

Factories that specialize in the manufacturing of soffit roll forming machines play a vital role in the supply chain of the construction industry. They not only produce the machines but also provide essential support and services, including

- Technical Support Ensuring that customers can operate machinery effectively and troubleshoot any issues that arise. - Maintenance Services Offering regular maintenance and repairs to keep machinery in optimal condition, thus extending the life of the equipment. - Training Programs Providing training for factory workers on the best practices for operating and maintaining roll forming machines.

The Future of Soffit Roll Forming Machine Factories

As construction techniques continue to evolve, the demand for innovative building materials like soffits will likely increase. Moreover, advancements in technology, such as automation and digital control systems, will further enhance the capabilities of soffit roll forming machines.

In conclusion, soffit roll forming machine factories are essential to the production of high-quality soffit panels used in modern architecture. Their ability to combine efficiency, customization, and precision makes them a cornerstone of the building materials industry. As the market continues to expand, these factories will no doubt play a pivotal role in shaping the future of construction.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025