Advanced Roll Forming Machines for High-Quality Decking and Panel Production Solutions

The Advancements in Decking Panel Roll Forming Machines

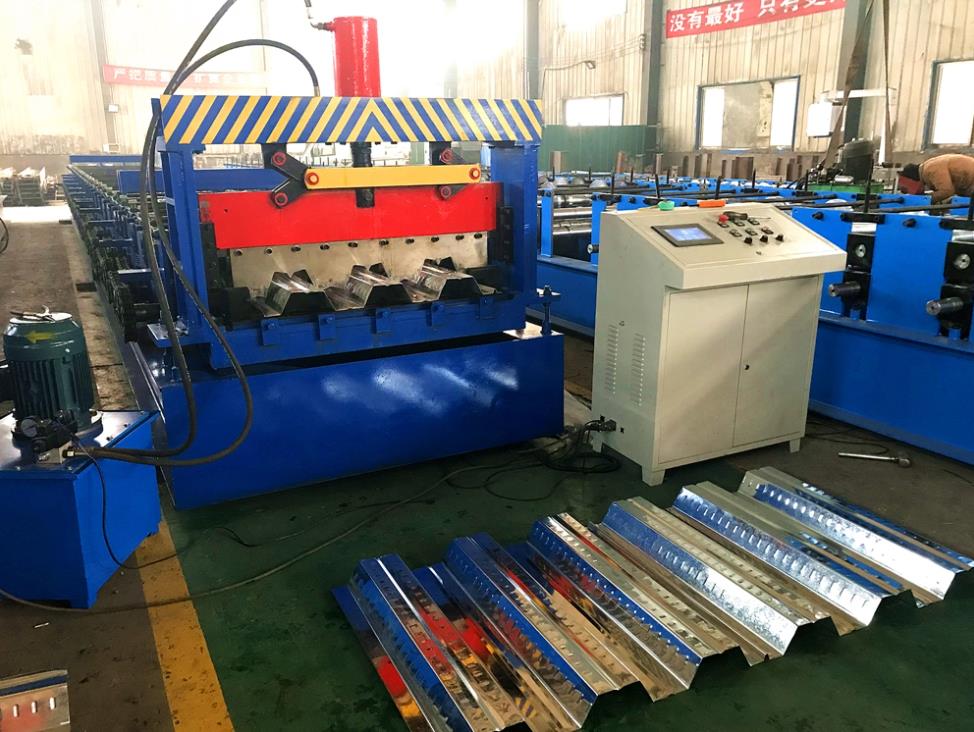

In the ever-evolving landscape of manufacturing, decking panel roll forming machines have become essential for industries involved in construction and building materials. These machines are designed to transform metal sheets into various profiles used for roofing, wall cladding, and decking applications. The efficiency and versatility of roll forming technology have made it an attractive choice for manufacturers seeking to improve production capabilities and reduce costs.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of sheet metal is progressively shaped into the desired cross-section. The process involves feeding the metal through a series of roller dies that gradually reshape the material. This method is highly efficient, allowing for high production rates with minimal waste, making it particularly suitable for the production of decking panels.

Key Features of Decking Panel Roll Forming Machines

Modern decking panel roll forming machines are equipped with advanced technology that enhances their performance. Some key features include

1. Customizable Die Sets Manufacturers can create specific profiles to meet unique architectural designs or client requirements. This flexibility allows for the production of various panel styles, ensuring compatibility with diverse building projects.

2. High-Speed Production New advancements in motor technology and automation have enabled machines to operate at higher speeds without sacrificing precision. This increase in production efficiency directly translates to lower labor costs and enhanced output.

3. Material Versatility Decking panel roll forming machines can work with a variety of materials, including galvanized steel, aluminum, and other alloys. This versatility allows manufacturers to cater to different market demands and eco-friendly preferences.

decking panel roll forming machine

4. Integrated Trimming and Cutting Systems Many roll forming machines come equipped with built-in trimming and cutting systems, allowing for precise lengths and dimensions. This feature reduces the need for additional machinery and streamlines the production process.

5. Automated Control Systems Advanced control systems facilitate easier operation and monitoring of the roll forming process. Operators can adjust settings in real time, ensuring consistency and quality throughout the production run.

Environmental Considerations

As the construction industry becomes increasingly aware of its environmental impact, decking panel roll forming machines contribute to sustainability efforts. The efficiency of the roll forming process means less material wastage, and the ability to use recyclable materials aligns with eco-friendly building practices. Furthermore, many manufacturers are incorporating energy-efficient technologies into their machines, reducing their carbon footprint.

Market Demand and Future Trends

With the rise in construction activities and an ongoing focus on sustainable building practices, the demand for decking panels manufactured using roll forming technology is expected to grow. The market is continually evolving, with trends leaning toward automation and smarter manufacturing solutions. Internet of Things (IoT) integration is also becoming prominent, allowing for real-time data collection and machine monitoring, thus enabling proactive maintenance and optimization.

Conclusion

Decking panel roll forming machines are revolutionizing the way building materials are produced. By combining efficiency, flexibility, and environmental responsibility, these machines play a critical role in modern manufacturing. As technology continues to advance, the capabilities of roll forming machines will likely expand, paving the way for innovative solutions that meet the demands of the ever-changing construction industry. Investing in such technology is not merely a choice for manufacturers but a necessity to remain competitive in a dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025