Jan . 25, 2025 23:54

Back to list

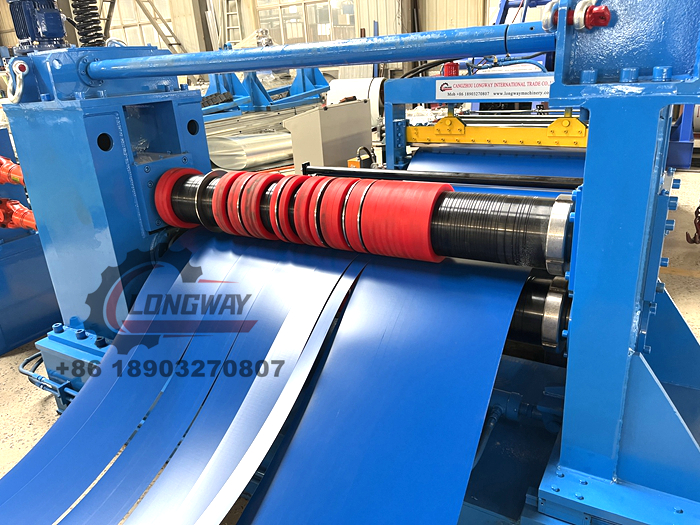

cladding roll forming machine

The silo roll forming machine stands at the forefront of modern manufacturing processes, embodying a seamless blend of precision engineering and innovative technology. This intricate piece of machinery has not only transformed the way silos are manufactured but has also established itself as an indispensable asset in industrial production, thanks to its numerous advantages that enhance operational efficiency and product quality.

Many manufacturers share their experiences of integrating silo roll forming machines into their production lines, noting not only an increase in efficiency but also a broader impact on their competitive edge in the marketplace. By maintaining state-of-the-art equipment, they illustrate their commitment to adopting the latest technological advancements, which translates into superior products and services offered to their client base. The sustainability aspect of using silo roll forming machines cannot be overlooked. By reducing material wastage and energy consumption, these machines contribute to more sustainable manufacturing practices. This is particularly relevant in today's environmentally-conscious market, where reducing carbon footprints and promoting sustainable development are not just desirable but essential. Such machines embody the innovative strides towards achieving eco-friendly industrial practices without compromising on product quality or manufacturing efficiency. Investing in a silo roll forming machine can transform a company's manufacturing capabilities. The combination of cutting-edge technology, expert operation, and reliable output poise these machines as a cornerstone of successful production strategies. As these machines continue to evolve, embracing more advancements and expanding their capabilities, they will undoubtedly reinforce their position as a trusted and authoritative presence in the field of industrial manufacturing. In summary, the silo roll forming machine is more than just a tool for shaping metal; it is a symbol of modern manufacturing innovation. It draws on deep expertise to deliver robust, reliable, and precise components critical for silo construction, enhancing the credibility and market reputation of companies around the globe. Understanding and leveraging the capabilities of such technology ensure that manufacturers are not only meeting current industrial demands but are also prepared to exceed future expectations.

Many manufacturers share their experiences of integrating silo roll forming machines into their production lines, noting not only an increase in efficiency but also a broader impact on their competitive edge in the marketplace. By maintaining state-of-the-art equipment, they illustrate their commitment to adopting the latest technological advancements, which translates into superior products and services offered to their client base. The sustainability aspect of using silo roll forming machines cannot be overlooked. By reducing material wastage and energy consumption, these machines contribute to more sustainable manufacturing practices. This is particularly relevant in today's environmentally-conscious market, where reducing carbon footprints and promoting sustainable development are not just desirable but essential. Such machines embody the innovative strides towards achieving eco-friendly industrial practices without compromising on product quality or manufacturing efficiency. Investing in a silo roll forming machine can transform a company's manufacturing capabilities. The combination of cutting-edge technology, expert operation, and reliable output poise these machines as a cornerstone of successful production strategies. As these machines continue to evolve, embracing more advancements and expanding their capabilities, they will undoubtedly reinforce their position as a trusted and authoritative presence in the field of industrial manufacturing. In summary, the silo roll forming machine is more than just a tool for shaping metal; it is a symbol of modern manufacturing innovation. It draws on deep expertise to deliver robust, reliable, and precise components critical for silo construction, enhancing the credibility and market reputation of companies around the globe. Understanding and leveraging the capabilities of such technology ensure that manufacturers are not only meeting current industrial demands but are also prepared to exceed future expectations.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products