Jan . 22, 2025 04:25

Back to list

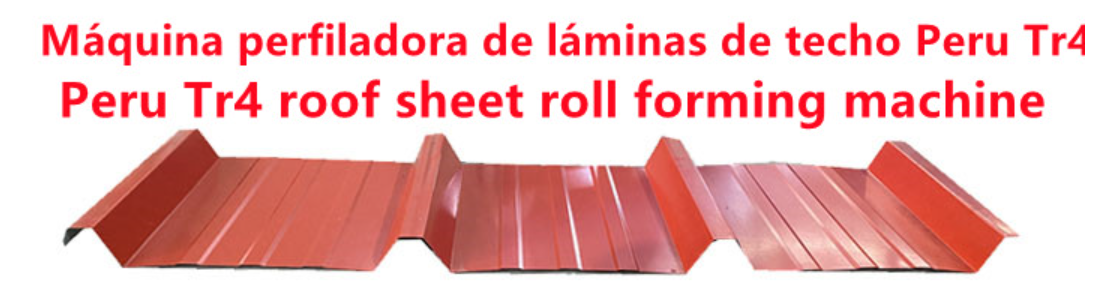

3 Rib Trapezoid roof sheet making machine

Navigating the world of sheet metal forming machines can feel like traversing a maze of technical jargon, brand comparisons, and price variability. Understanding the price of these machines involves more than just focusing on the numbers; it demands an exploration of factors influencing cost, value for investment, and the anticipated return on investment. In this comprehensive guide, we will dissect the various aspects contributing to the pricing of sheet metal forming machines, ensuring a well-rounded approach for prospective buyers.

Moreover, geographic location affects pricing due to factors like shipping, import duties, and regional taxations. Buyers need to factor in these hidden costs when evaluating the overall expense. Opting for locally manufactured machines can sometimes be economically advantageous considering potential savings on shipping and quicker availability of technical support. Advances in technology play a continual role in shaping pricing trends. With Industry 4.0 on the rise, machines equipped with smart technology, IoT capabilities, and real-time data analytics are becoming standard. While initially priced higher, they offer substantial savings and operational efficiencies by minimizing downtime and optimizing production processes through predictive maintenance and enhanced monitoring. In making an informed purchasing decision, prospective buyers should consider consulting industry experts or existing users of sheet metal forming machines. Real-world experiences and expert reviews provide invaluable insights into the functional and economic performance of these machines beyond what product descriptions might convey. Ultimately, understanding the price of a sheet metal forming machine is about evaluating the balance between upfront costs and the potential for increased productivity, efficiency, and profitability. A strategic approach involving thorough research, understanding enterprise needs, and aligning them with market offerings can guide businesses toward making an investment that not only meets their immediate requirements but also aligns with long-term growth objectives.

Moreover, geographic location affects pricing due to factors like shipping, import duties, and regional taxations. Buyers need to factor in these hidden costs when evaluating the overall expense. Opting for locally manufactured machines can sometimes be economically advantageous considering potential savings on shipping and quicker availability of technical support. Advances in technology play a continual role in shaping pricing trends. With Industry 4.0 on the rise, machines equipped with smart technology, IoT capabilities, and real-time data analytics are becoming standard. While initially priced higher, they offer substantial savings and operational efficiencies by minimizing downtime and optimizing production processes through predictive maintenance and enhanced monitoring. In making an informed purchasing decision, prospective buyers should consider consulting industry experts or existing users of sheet metal forming machines. Real-world experiences and expert reviews provide invaluable insights into the functional and economic performance of these machines beyond what product descriptions might convey. Ultimately, understanding the price of a sheet metal forming machine is about evaluating the balance between upfront costs and the potential for increased productivity, efficiency, and profitability. A strategic approach involving thorough research, understanding enterprise needs, and aligning them with market offerings can guide businesses toward making an investment that not only meets their immediate requirements but also aligns with long-term growth objectives.

Latest news

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025

Related Products