Roof Panel Production Equipment Supplier for Durable Roofing Solutions

Understanding Roof Sheet Forming Machine Manufacturers

In the realm of modern construction and architecture, the demand for durable and aesthetically pleasing roofing materials has surged. This need has paved the way for innovative machinery designed to produce high-quality roofing sheets efficiently. Among these innovations is the roof sheet forming machine, a vital piece of equipment that plays a crucial role in the roofing industry.

What is a Roof Sheet Forming Machine?

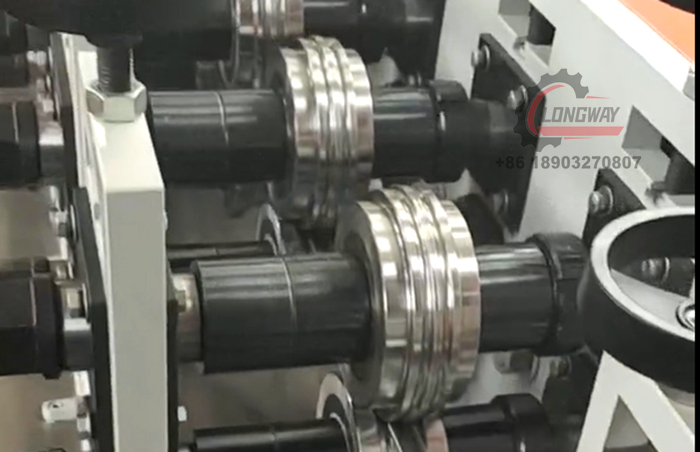

A roof sheet forming machine is a specialized piece of equipment used to manufacture metal roofing sheets from coils of raw material, typically steel or aluminum. The machine processes these coils through a series of rollers, which shape the metal into the desired profile, such as corrugated or trapezoidal sheets. The resulting sheets are not only robust but also lightweight and resistant to various environmental factors, making them ideal for construction projects ranging from residential homes to large commercial buildings.

The Role of Manufacturers

Manufacturers of roof sheet forming machines play a vital role in the construction supply chain. They are responsible for designing and producing machines that can operate efficiently with high precision. These manufacturers focus on several critical aspects

1. Technology and Innovation Leading manufacturers continuously invest in research and development to improve the performance of their machines. This includes enhancing the efficiency, speed, and accuracy of the sheet forming process. Advanced technologies such as computer numerical control (CNC) systems and automation are often incorporated to streamline production and reduce labor costs.

2. Customization Each roofing project has its unique specifications. Therefore, top manufacturers offer customized solutions tailored to their clients’ requirements. This could mean producing machines that can create specific profiles or accommodate various material types. The flexibility to adapt to different needs is a significant advantage in today’s competitive market.

roof sheet forming machine manufacturer

3. Quality Assurance Quality is paramount in the construction industry. Roof sheet forming machine manufacturers emphasize rigorous testing and quality control measures to ensure their products meet industry standards. The durability and reliability of the machines are crucial, as they directly impact the quality of the roofing sheets produced.

4. Customer Support and Service A reputable manufacturer doesn’t just sell machinery; they also provide comprehensive support services. This includes installation, training, and ongoing maintenance. Effective after-sales support is essential to help customers maximize their production efficiency and minimize downtime.

Market Trends and Challenges

The market for roof sheet forming machines is influenced by several trends in the construction industry. As green building practices gain popularity, there is a rising demand for eco-friendly materials and processes. Manufacturers must adapt to these trends by offering machines that can work with recycled or sustainable materials.

Moreover, the global push for infrastructure development in emerging economies presents an exciting opportunity for machine manufacturers. Increased urbanization and rising population demands lead to more construction projects, thereby increasing the need for roofing solutions.

However, challenges also exist. Fluctuating raw material prices, supply chain disruptions, and economic uncertainties can impact production costs and timelines. Manufacturers must navigate these challenges while ensuring competitiveness in both local and international markets.

Conclusion

In conclusion, roof sheet forming machine manufacturers are integral to the construction industry. Their commitment to innovation, customization, quality assurance, and customer service shapes the roofing solutions available today. As the market continues to evolve, these manufacturers must stay ahead of trends and challenges to provide efficient, high-quality machinery that meets the demands of modern construction. As a result, they contribute significantly to building resilient infrastructures that cater to an ever-expanding global population. The future of roofing will undoubtedly be shaped by the advancements and capabilities of these manufacturers, making them prominent players in the construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025