Efficient Slitting Line Manufacturing Solutions for Precision Metal Processing

The Benefits of Investing in a Simple Slitting Line Factory

In the competitive world of manufacturing, companies are continually seeking ways to enhance efficiency and maximize productivity. One of the most effective strategies to achieve these goals is by investing in specialized machinery that can streamline production processes. A simple slitting line factory is one such investment that can offer significant advantages to businesses involved in metal processing, particularly in the steel and aluminum industries.

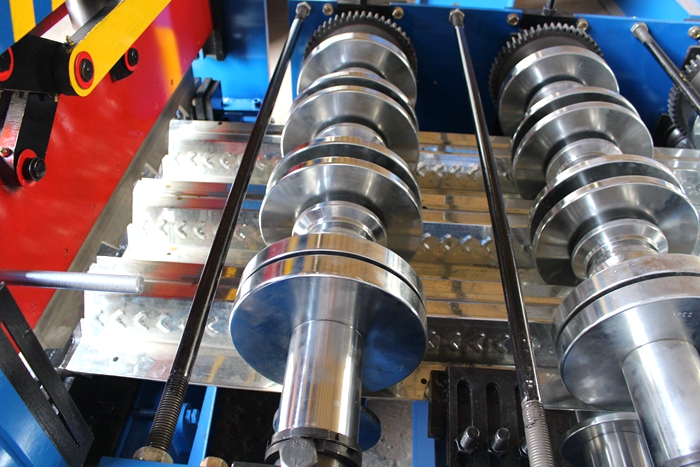

Understanding Slitting Lines

Before delving into the benefits of a simple slitting line factory, it is essential to understand what slitting lines are and how they function. A slitting line is an advanced machine that takes large coils of metal and slits them down into narrower strips of various widths. This process allows manufacturers to modify the width of the material according to specific requirements, making it an invaluable asset for companies that supply materials for various downstream applications.

Advantages of a Simple Slitting Line Factory

1. Increased Production Efficiency

One of the most significant benefits of a simple slitting line factory is the increase in production efficiency. Traditional methods of slitting materials can be time-consuming and labor-intensive. However, with a simple slitting line, the process becomes automated, leading to higher throughput and lower production costs. The automation of the slitting process minimizes errors, reduces waste, and optimizes the overall workflow, thereby allowing manufacturers to focus on other critical aspects of their operations.

Investing in a simple slitting line can be cost-effective in the long run. While initial capital expenditure may be considerable, the savings accrued through reduced labor costs, lower scrap rates, and improved operational efficiency can lead to a rapid return on investment. Furthermore, by producing narrower strips in-house, companies can eliminate the need for outsourcing, further reducing operational expenses.

simple slitting line factory

3. Versatility and Customization

A simple slitting line factory can cater to a wide range of products and specifications, allowing manufacturers to serve diverse markets. The machinery is often equipped with advanced features that allow for easy adjustments, enabling operators to switch between different widths and materials quickly. This versatility ensures that manufacturers can respond promptly to changing market demands and customer preferences, maintaining a competitive edge.

4. Quality Control

Quality is paramount in manufacturing, particularly in industries that rely on precision-engineered materials. A simple slitting line factory enhances quality control by utilizing advanced technology to ensure accuracy throughout the slitting process. With consistent and precise slitting, manufacturers can produce high-quality strips that meet industry standards, reducing the likelihood of defects and returns.

5. Space Efficiency

Many businesses face challenges in managing production space. A simple slitting line is typically compact and designed for efficient space utilization. This space-saving design allows manufacturers to integrate the slitting line into their existing production environments without requiring extensive modifications. With a smaller footprint, businesses can increase their production capacity without the need for investing in larger facilities.

Conclusion

In conclusion, the decision to invest in a simple slitting line factory can profoundly impact a manufacturing company’s operational capabilities. The advantages of increased efficiency, cost-effectiveness, versatility, improved quality control, and space efficiency present compelling reasons for businesses to consider adopting this technology. As manufacturing continues to evolve, companies that leverage advanced machinery like a simple slitting line will be better positioned to respond to market demands and stay ahead of the competition. With the right investment, the future of metal processing is bright, promising enhanced productivity and profitability for those willing to embrace innovation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025