Feb . 10, 2025 10:42

Back to list

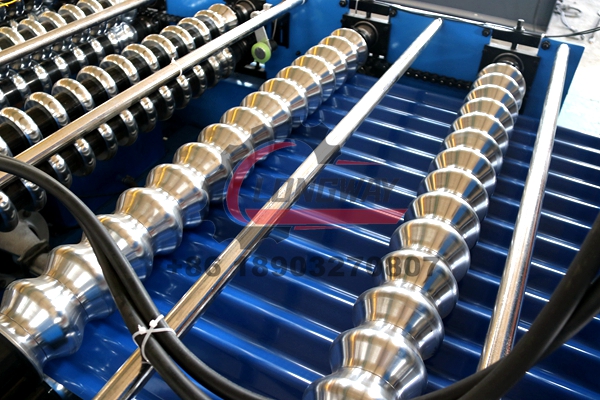

roof ridge cap roll forming machine

Roof ridge cap roll forming machines have revolutionized the construction and roofing industries through advanced automation, precision engineering, and enhanced production capabilities. These machines are not only considered a staple for manufacturers who specialize in building materials, but also play a critical role in ensuring the longevity and aesthetics of roofing systems.

Authoritativeness in the realm of roof ridge cap roll forming machines is solidified through adherence to industry standards and continuous innovation. Leading manufacturers of these machines invest heavily in research and development, pushing the boundaries of what is possible in metal forming and fabrication. Their commitment to quality is evident in the reliability and durability of the machines they produce. Experts in the industry recognize these machines as benchmarks of quality and performance, often choosing them over other equipment due to their proven track record. Trustworthiness is perhaps the most compelling factor that cements a roof ridge cap roll forming machine's place in the industry. Manufacturers build trust by providing robust after-sales support, including comprehensive training programs, responsive customer service, and readily available replacement parts. This support network ensures that users can maintain peak performance of their machines, minimizing downtime and maximizing productivity. Additionally, the efficiency of these machines reduces material waste and energy consumption, aligning with the growing emphasis on sustainable manufacturing practices. In conclusion, roof ridge cap roll forming machines stand as a testament to mechanical innovation and industry excellence. Their impact on product efficiency, quality, and adaptability has made them indispensable tools for those specializing in roofing and construction. These machines not only boost production capabilities but also elevate the standard of roofing materials, ensuring structures are outfitted with components that boast both functionality and aesthetic appeal. As the industry continues to evolve, roof ridge cap roll forming machines will undoubtedly remain at the forefront, setting the standard for what is achievable in the realm of architectural manufacturing.

Authoritativeness in the realm of roof ridge cap roll forming machines is solidified through adherence to industry standards and continuous innovation. Leading manufacturers of these machines invest heavily in research and development, pushing the boundaries of what is possible in metal forming and fabrication. Their commitment to quality is evident in the reliability and durability of the machines they produce. Experts in the industry recognize these machines as benchmarks of quality and performance, often choosing them over other equipment due to their proven track record. Trustworthiness is perhaps the most compelling factor that cements a roof ridge cap roll forming machine's place in the industry. Manufacturers build trust by providing robust after-sales support, including comprehensive training programs, responsive customer service, and readily available replacement parts. This support network ensures that users can maintain peak performance of their machines, minimizing downtime and maximizing productivity. Additionally, the efficiency of these machines reduces material waste and energy consumption, aligning with the growing emphasis on sustainable manufacturing practices. In conclusion, roof ridge cap roll forming machines stand as a testament to mechanical innovation and industry excellence. Their impact on product efficiency, quality, and adaptability has made them indispensable tools for those specializing in roofing and construction. These machines not only boost production capabilities but also elevate the standard of roofing materials, ensuring structures are outfitted with components that boast both functionality and aesthetic appeal. As the industry continues to evolve, roof ridge cap roll forming machines will undoubtedly remain at the forefront, setting the standard for what is achievable in the realm of architectural manufacturing.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products