Feb . 10, 2025 10:50

Back to list

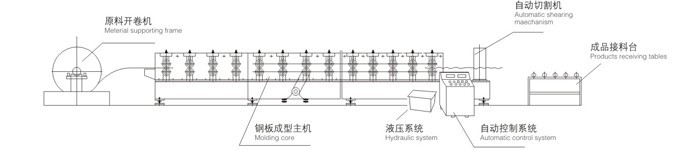

roofing corrugated sheet roll forming machine

Exploring the World of Roofing Corrugated Sheet Roll Forming Machines

A crucial factor to consider is the machine's control system. Modern roll forming machines are often equipped with advanced control systems that facilitate precise adjustments and real-time monitoring. This technological integration enhances accuracy in production while maintaining high standards for quality. Furthermore, some machines come with programmable logic controllers (PLC) and Human-Machine Interfaces (HMI), offering intuitive and user-friendly operation, which is a boon for operators with varying levels of expertise. When discussing expertise, the selection of a machine manufacturer plays an essential role. Top-tier manufacturers not only provide high-quality machines but also offer comprehensive customer support and maintenance services. This relationship fosters operational efficiency and ensures that any technical challenges are swiftly addressed. During my career, collaborating with reputable manufacturers has been pivotal in maintaining continuous production flow and machine longevity. From an authoritativeness standpoint, understanding the latest advancements in roll forming technology is crucial. Recent innovations focus on energy efficiency and environmental impact. Machines are now designed to consume less power without compromising productivity, aligning with global sustainability goals. For businesses aiming to strengthen their market position, adopting these advanced machines reflects a commitment to environmental responsibility and operational excellence. Trustworthiness is further reinforced through third-party certifications and compliance with industry standards. Machines that adhere to ISO and CE certifications provide an added layer of assurance to investors and end-users regarding their reliability and safety standards. Consulting with experts and reviewing case studies from past implementations provide valuable insights into the machine's long-term performance. In conclusion, roofing corrugated sheet roll forming machines are a cornerstone in modern construction, converting raw metal into essential building materials with precision and efficiency. As a construction professional or business owner, the emphasis should be on selecting a machine that aligns with your project needs, guarantees operational efficiency, and supports sustainability. The road to improved productivity and profitability in the roofing sector undoubtedly runs through the heart of these advanced machines.

A crucial factor to consider is the machine's control system. Modern roll forming machines are often equipped with advanced control systems that facilitate precise adjustments and real-time monitoring. This technological integration enhances accuracy in production while maintaining high standards for quality. Furthermore, some machines come with programmable logic controllers (PLC) and Human-Machine Interfaces (HMI), offering intuitive and user-friendly operation, which is a boon for operators with varying levels of expertise. When discussing expertise, the selection of a machine manufacturer plays an essential role. Top-tier manufacturers not only provide high-quality machines but also offer comprehensive customer support and maintenance services. This relationship fosters operational efficiency and ensures that any technical challenges are swiftly addressed. During my career, collaborating with reputable manufacturers has been pivotal in maintaining continuous production flow and machine longevity. From an authoritativeness standpoint, understanding the latest advancements in roll forming technology is crucial. Recent innovations focus on energy efficiency and environmental impact. Machines are now designed to consume less power without compromising productivity, aligning with global sustainability goals. For businesses aiming to strengthen their market position, adopting these advanced machines reflects a commitment to environmental responsibility and operational excellence. Trustworthiness is further reinforced through third-party certifications and compliance with industry standards. Machines that adhere to ISO and CE certifications provide an added layer of assurance to investors and end-users regarding their reliability and safety standards. Consulting with experts and reviewing case studies from past implementations provide valuable insights into the machine's long-term performance. In conclusion, roofing corrugated sheet roll forming machines are a cornerstone in modern construction, converting raw metal into essential building materials with precision and efficiency. As a construction professional or business owner, the emphasis should be on selecting a machine that aligns with your project needs, guarantees operational efficiency, and supports sustainability. The road to improved productivity and profitability in the roofing sector undoubtedly runs through the heart of these advanced machines.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products