Feb . 10, 2025 10:58

Back to list

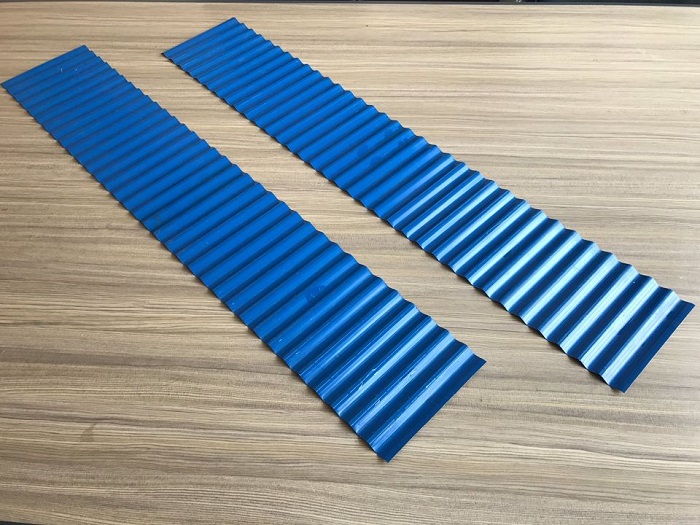

roofing sheets roll forming machine

The roofing sheets roll forming machine is a revolutionary piece of equipment transforming the construction industry. As an expert in this field with years of experience, I can attest to its profound impact on efficiency and quality in roofing projects. This machine is engineered to produce continuous metal roofing sheets, precisely customized to length and design specifications, eliminating waste and streamlining the production process.

Understanding the mechanics and functionality of the roofing sheets roll forming machine is crucial for leveraging its full potential. With comprehensive training and expertise, operators can maximize productivity and maintain the highest standards of safety and output. As an authority in roofing machinery, I emphasize the importance of regular maintenance and calibration of these machines to ensure long-term sustainability and efficiency. Businesses that invest in a roofing sheets roll forming machine also gain a competitive edge by offering customized solutions tailored to client needs. This adaptability not only expands service offerings but also strengthens client relationships and customer satisfaction, as bespoke solutions are highly valued in today’s marketplace. Moreover, as sustainability becomes increasingly important, the machine’s ability to minimize material wastage aligns perfectly with green building practices. In conclusion, the roofing sheets roll forming machine is more than just a tool; it is a cornerstone in modern roofing construction, essential for businesses aiming to deliver quality, efficiency, and customizability in their roofing solutions. With the right expertise, businesses can harness its capabilities to drive growth, improve client satisfaction, and reinforce their reputation as industry leaders in sustainable and innovative construction solutions.

Understanding the mechanics and functionality of the roofing sheets roll forming machine is crucial for leveraging its full potential. With comprehensive training and expertise, operators can maximize productivity and maintain the highest standards of safety and output. As an authority in roofing machinery, I emphasize the importance of regular maintenance and calibration of these machines to ensure long-term sustainability and efficiency. Businesses that invest in a roofing sheets roll forming machine also gain a competitive edge by offering customized solutions tailored to client needs. This adaptability not only expands service offerings but also strengthens client relationships and customer satisfaction, as bespoke solutions are highly valued in today’s marketplace. Moreover, as sustainability becomes increasingly important, the machine’s ability to minimize material wastage aligns perfectly with green building practices. In conclusion, the roofing sheets roll forming machine is more than just a tool; it is a cornerstone in modern roofing construction, essential for businesses aiming to deliver quality, efficiency, and customizability in their roofing solutions. With the right expertise, businesses can harness its capabilities to drive growth, improve client satisfaction, and reinforce their reputation as industry leaders in sustainable and innovative construction solutions.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products