Feb . 10, 2025 10:38

Back to list

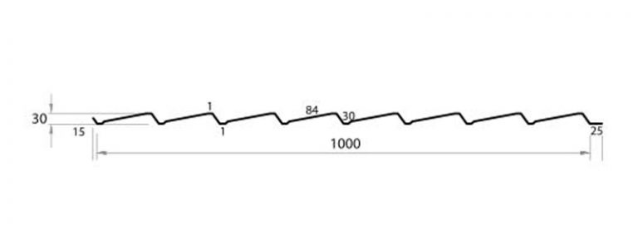

320 Cladding wall panel roll former

The roof and wall panel roll forming machine is an intricate piece of machinery that stands as a cornerstone in modern construction manufacturing processes. As one of the most technologically advanced solutions available today, this machine is designed with precision to create consistent, high-quality roof and wall panels. For any construction professional or manufacturing expert, understanding the technical details, operational benefits, and industry implications of this equipment is essential.

Trustworthiness is a pivotal aspect of a roof and wall panel roll forming machine's appeal. Precision engineering ensures each unit is consistently up to the task, producing panels that meet exact specifications every time. This not only bolsters the machine’s reliability but also fosters trust among end-users, who depend on these panels for safeguarding structural integrity in buildings. Customer testimonials and long-term case studies provide further evidence of these machines’ dependability in diverse environments and challenging conditions. Moreover, the environmental impact of using roll forming machines cannot be overstated. By optimizing the material usage and reducing waste, these machines contribute to more sustainable building practices. The lean manufacturing process is not only cost-effective but works towards smaller carbon footprints, aligning with global efforts to curb environmental issues. Businesses are increasingly recognizing these benefits and choosing to invest accordingly, trusting in the machine's capability to deliver sustainable, top-quality panels. In conclusion, the roof and wall panel roll forming machine is indispensable in contemporary construction. It embodies both the advancements of modern technology and the pursuit of sustainability within the industry. As construction demands continue to evolve, the machines’ expertise, proven experience, authoritative status, and trustworthy performance ensure they remain integral to efficient, reliable panel production. For industry professionals, investing time in understanding and incorporating this technology can lead to enhanced productivity, safety, and environmental consciousness, all while maintaining the highest standards of quality and durability in construction materials.

Trustworthiness is a pivotal aspect of a roof and wall panel roll forming machine's appeal. Precision engineering ensures each unit is consistently up to the task, producing panels that meet exact specifications every time. This not only bolsters the machine’s reliability but also fosters trust among end-users, who depend on these panels for safeguarding structural integrity in buildings. Customer testimonials and long-term case studies provide further evidence of these machines’ dependability in diverse environments and challenging conditions. Moreover, the environmental impact of using roll forming machines cannot be overstated. By optimizing the material usage and reducing waste, these machines contribute to more sustainable building practices. The lean manufacturing process is not only cost-effective but works towards smaller carbon footprints, aligning with global efforts to curb environmental issues. Businesses are increasingly recognizing these benefits and choosing to invest accordingly, trusting in the machine's capability to deliver sustainable, top-quality panels. In conclusion, the roof and wall panel roll forming machine is indispensable in contemporary construction. It embodies both the advancements of modern technology and the pursuit of sustainability within the industry. As construction demands continue to evolve, the machines’ expertise, proven experience, authoritative status, and trustworthy performance ensure they remain integral to efficient, reliable panel production. For industry professionals, investing time in understanding and incorporating this technology can lead to enhanced productivity, safety, and environmental consciousness, all while maintaining the highest standards of quality and durability in construction materials.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products