Jan . 29, 2025 02:15

Back to list

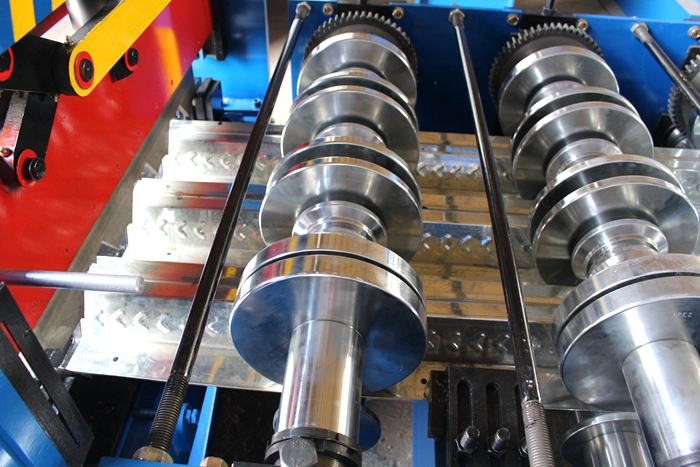

roll forming suppliers

In the dynamic world of manufacturing, roll forming stands out as a versatile and efficient process for shaping metal. Roll forming suppliers play a crucial role in a variety of industries by providing customized, precision-engineered solutions that meet the demanding needs of today's market. With the emphasis on quality and innovation, the collaboration with experienced and authoritative roll forming suppliers becomes indispensable for any manufacturer aiming to excel.

Trustworthiness in roll forming suppliers is established through consistent delivery of high-quality products and services. Trust is built over time by fulfilling promises, maintaining transparency in all dealings, and providing reliable customer service. Reliable suppliers implement rigorous quality assurance measures to ensure that every product leaving their facility meets exact client specifications and industry standards. Many offer traceability and full documentation to support quality compliance, which is critical in industries with stringent regulatory requirements, like automotive, aerospace, or construction. In addition to their technical capabilities, trusted suppliers value the relationships with their clients. Long-term partnerships are often formed through open communication and collaboration, ensuring that clients receive support throughout the project lifecycle—from initial consultation and planning to prototyping, production, and ongoing maintenance and support. This comprehensive service approach instills confidence and reinforces the supplier’s role as a valuable ally in achieving business goals. As the manufacturing landscape continues to evolve, embracing sustainability and digital transformation becomes increasingly important. Leading roll forming suppliers are adopting sustainable practices and smart manufacturing techniques that reduce waste, conserve energy, and improve efficiency. Investing in advanced data analytics and automation technologies, these suppliers offer enhanced production capabilities, enable predictive maintenance, and ensure quicker response times to market demands. This progressive mindset not only benefits their clients in terms of cost savings and improved lead times but also contributes to a more sustainable industry overall. In conclusion, choosing the right roll forming supplier is fundamental to achieving exceptional product quality and operational efficiency. Experience, expertise, authoritativeness, and trustworthiness are the pillars that form the foundation of outstanding roll forming suppliers. By aligning with such suppliers, manufacturers gain access to best-in-class resources, pioneering technology, and unwavering support, paving the way for innovation and growth in their respective fields.

Trustworthiness in roll forming suppliers is established through consistent delivery of high-quality products and services. Trust is built over time by fulfilling promises, maintaining transparency in all dealings, and providing reliable customer service. Reliable suppliers implement rigorous quality assurance measures to ensure that every product leaving their facility meets exact client specifications and industry standards. Many offer traceability and full documentation to support quality compliance, which is critical in industries with stringent regulatory requirements, like automotive, aerospace, or construction. In addition to their technical capabilities, trusted suppliers value the relationships with their clients. Long-term partnerships are often formed through open communication and collaboration, ensuring that clients receive support throughout the project lifecycle—from initial consultation and planning to prototyping, production, and ongoing maintenance and support. This comprehensive service approach instills confidence and reinforces the supplier’s role as a valuable ally in achieving business goals. As the manufacturing landscape continues to evolve, embracing sustainability and digital transformation becomes increasingly important. Leading roll forming suppliers are adopting sustainable practices and smart manufacturing techniques that reduce waste, conserve energy, and improve efficiency. Investing in advanced data analytics and automation technologies, these suppliers offer enhanced production capabilities, enable predictive maintenance, and ensure quicker response times to market demands. This progressive mindset not only benefits their clients in terms of cost savings and improved lead times but also contributes to a more sustainable industry overall. In conclusion, choosing the right roll forming supplier is fundamental to achieving exceptional product quality and operational efficiency. Experience, expertise, authoritativeness, and trustworthiness are the pillars that form the foundation of outstanding roll forming suppliers. By aligning with such suppliers, manufacturers gain access to best-in-class resources, pioneering technology, and unwavering support, paving the way for innovation and growth in their respective fields.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products