Innovative Rollforming Techniques for Efficient Manufacturing Solutions in Modern Industries

Exploring the World of Rollformers An Insight into Rollforming Factories

Rollforming is a manufacturing process that involves the continuous bending of metal sheets or strips into desired shapes. This technique has gained immense popularity in various industries due to its efficiency and versatility. At the heart of this process lies the rollformer—a specialized machine used in rollforming factories. This article delves into the significance of rollformers, the operation of rollforming factories, and the trends shaping this industry.

The Role of Rollformers

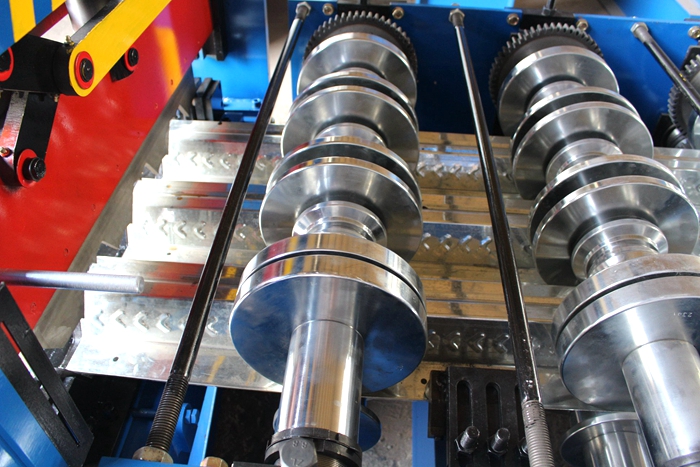

Rollformers are essential in transforming flat metal sheets into complex profiles with precision and speed. They function by feeding a continuous strip of metal through a series of rollers, each designed to progressively shape the metal into its final form. This process allows for high-volume production with minimal waste, making rollforming a cost-effective solution for many manufacturers.

The versatility of rollformers enables the production of a wide array of products, ranging from roofing panels and metal studs to railings and automotive components. Industries that benefit from rollforming include construction, automotive, aerospace, and HVAC. The ability to produce custom profiles tailored to specific applications further enhances the appeal of rollformers in the manufacturing landscape.

Inside a Rollforming Factory

A typical rollforming factory is a hub of activity, featuring advanced machinery and skilled laborers working in tandem. The factory layout is typically designed for efficiency, with raw materials arriving at one end and finished products being dispatched at the other. The process begins with the careful selection of raw materials, usually cold-rolled or galvanized steel, which are selected based on the requirements of the final product.

rollformers factories

Once the raw materials are prepared, they are fed into the rollforming machine. The precision engineering of the rollformer ensures that the metal sheet is shaped accurately as it passes through the sequential rollers. Quality control is a critical aspect of the process, with automated systems often in place to monitor the dimensions and integrity of the formed profiles. This ensures that every product meets the required specifications and maintains the high standards expected in today's competitive marketplace.

Innovations and Trends

The rollforming industry has witnessed significant innovations in recent years. Automation and digitalization are revolutionizing the operations of rollforming factories. Advanced software solutions allow for the precise design and simulation of complex profiles, significantly reducing setup times and enhancing product development. Additionally, the integration of robotics within factories has improved efficiency, allowing for better handling of materials and increased throughput.

Sustainability is another trend shaping the future of rollforming. As industries worldwide strive to reduce their carbon footprint, rollforming factories are adopting greener practices. This includes sourcing recycled materials, implementing energy-efficient machinery, and minimizing waste during the manufacturing process. The push for environmentally friendly practices not only meets regulatory requirements but also appeals to an increasingly eco-conscious market.

Moreover, the demand for lightweight and high-strength materials in industries such as automotive and aerospace has spurred innovations in the types of metals used in rollforming. New alloys and advanced materials are being developed and incorporated into rollforming processes, further expanding the application range of rollformers.

Conclusion

In conclusion, rollforming factories represent a vital component of modern manufacturing, leveraging the capabilities of rollformers to produce a wide range of products efficiently and effectively. With ongoing innovations in technology, automation, and sustainability, the future of rollforming looks promising. As industries continue to evolve, rollforming factories will remain at the forefront, adapting to meet the changing demands of the global market while maintaining a commitment to quality and efficiency. The journey of rollforming, from raw material to finished product, symbolizes the ingenuity and resilience of the manufacturing sector in the 21st century.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025