box gutter production equipment manufacturing facility solutions for efficient drainage systems

The Box Gutter Machine Factory A Hub of Innovation in Metalworking

In the modern era of construction and architectural design, the importance of efficient drainage systems cannot be overstated. Among the numerous components that contribute to a building's water management system, box gutters play a pivotal role. As such, box gutter machine factories have emerged as integral players in the manufacturing industry, transforming raw materials into essential drainage solutions.

Understanding Box Gutters

Before delving into the intricacies of box gutter machine factories, it's essential to understand what box gutters are. Unlike traditional rounded gutters, box gutters possess a rectangular or square profile, allowing for a more significant water-carrying capacity. Their robust design makes them suitable for flat or low-pitched roofs and often enhances the aesthetic appeal of modern buildings. These gutters can be made from various materials, including steel, aluminum, copper, and PVC, each presenting unique benefits such as durability, corrosion resistance, and ease of installation.

The Role of Box Gutter Machine Factories

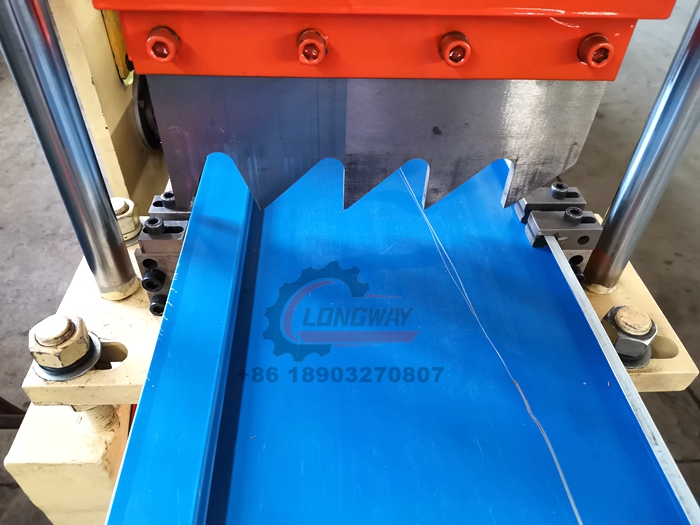

Box gutter machine factories specialize in the production of machines that create these essential drainage components. These factories are equipped with advanced technology, allowing for the rapid and efficient manufacturing of box gutters. The process begins with the procurement of high-quality raw materials, typically in coil form, which are fed into automated machines. These machines are designed to cut, shape, and fold the material into the desired dimensions of box gutters.

One of the critical advantages of box gutter machine factories is their ability to produce custom sizes and configurations. This capability is particularly beneficial for contractors and builders who are often tasked with meeting specific architectural requirements. By utilizing specialized machinery, factories can create unique designs that align with a building's aesthetic while ensuring optimal functionality.

Innovations in Manufacturing Techniques

The landscape of manufacturing is continually evolving, and box gutter machine factories are no exception. Many factories are now integrating smart technologies and automation into their production lines. Automated cutting and bending machines equipped with computer numerical control (CNC) have drastically improved precision, reducing waste and enhancing production speed.

box gutter machine factory

Furthermore, the implementation of Industry 4.0 principles has led to smarter operations. Factories now collect data on machine performance, production rates, and material usage, allowing for real-time adjustments and more efficient workflows. This embrace of technology not only conserves resources but also minimizes the environmental impact, making box gutter production more sustainable.

Quality Control and Compliance

In the realm of construction, quality assurance is of utmost importance. Box gutter machine factories adhere to stringent quality control measures to ensure that the products manufactured meet industry standards and regulations. Regular inspections are conducted at various stages of the production process, encompassing material sourcing, machine calibration, and final product evaluation.

Moreover, factories often collaborate with industry associations to stay updated on the latest building codes. This collaboration ensures that the box gutters produced are not only of high quality but also compliant with local and national regulations. Such diligence fosters trust with customers, making these factories reputable sources for box gutter solutions.

The Future of Box Gutter Machine Factories

Looking ahead, the future of box gutter machine factories appears promising. As urbanization continues to rise and architectural designs become increasingly complex, the demand for innovative drainage solutions will only grow. Challenges regarding climate change and extreme weather events will also drive the need for more efficient water management systems, further solidifying the role of box gutters.

Moreover, advancements in materials science may lead to the development of new, more efficient gutter materials. Factories that remain agile and adaptive to these changes will be well-positioned to lead the market. Investments in research and development, alongside sustainable manufacturing practices, will be crucial for long-term success.

Conclusion

Box gutter machine factories play a vital role in the construction industry, delivering high-quality, efficient solutions for water management. By leveraging technology and adhering to strict quality standards, these factories not only meet the demands of modern architecture but also contribute to a more sustainable future. As they continue to innovate and adapt, box gutter machine factories will undoubtedly remain at the forefront of metalworking and construction solutions for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025