roll former machine companies

The Rise of Roll Former Machine Companies Innovations and Market Growth

In recent years, the manufacturing industry has witnessed a significant shift towards automation and efficiency, largely driven by advancements in technology and the growing demand for high-quality metal products. Among the key players in this evolution are roll former machine companies, which specialize in producing machinery used to shape and transform metal sheets into various forms. This article explores the emergence of roll former machine companies, their technological innovations, and their impact on the market.

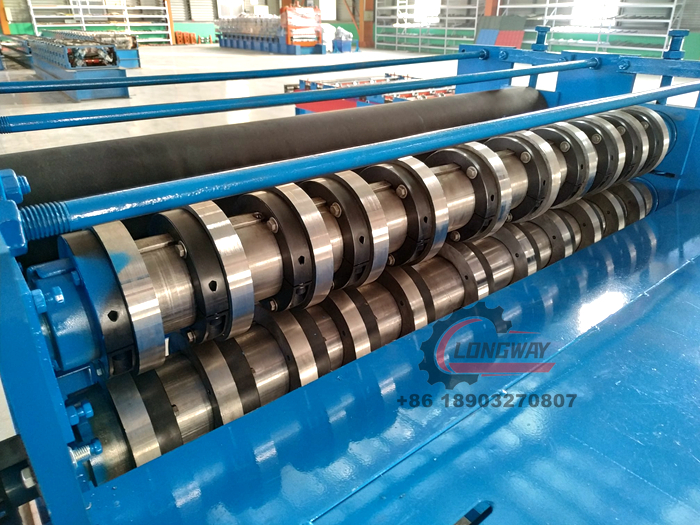

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is passed through consecutive pairs of rolls to create a desired cross-section. This process is not only cost-effective but also produces highly accurate and repeatable parts. As industries such as construction, automotive, and aerospace continue to expand, the need for roll forming technology has surged. Companies that manufacture roll former machines are capitalizing on this growth, offering state-of-the-art solutions designed to meet the diverse needs of their clients.

One of the most significant innovations in roll forming technology comes from advancements in automation and computerization. Modern roll former machines are equipped with sophisticated software that enables manufacturers to design complex profiles with ease. This technology not only streamlines the production process but also enhances production flexibility, allowing companies to quickly switch between different product designs without extensive downtime. Additionally, the integration of Industry 4.0 principles, such as IoT (Internet of Things) capabilities, enables real-time monitoring and data collection, helping businesses optimize their operations and reduce waste.

roll former machine companies

Another critical trend is the focus on sustainability within the roll forming industry. As companies strive to reduce their carbon footprint, many roll former machine manufacturers are developing energy-efficient machines that consume less power and generate minimal waste. Some companies have also begun to explore the use of recycled materials, producing machines that can work effectively with eco-friendly inputs. This not only aligns with global sustainability goals but also attracts environmentally conscious clients looking to enhance their green credentials.

The global market for roll former machine companies is expanding rapidly, driven by increasing urbanization and infrastructure development. Regions such as Asia-Pacific, North America, and Europe are witnessing significant investments in construction and manufacturing, fueling demand for roll forming equipment. Furthermore, with the rise of e-commerce and the need for efficient supply chains, roll former machines are becoming integral to producing components for packaging, shipping, and logistics.

In conclusion, roll former machine companies are at the forefront of manufacturing innovation, playing a crucial role in transforming the metalworking landscape. With advancements in technology, a focus on sustainability, and a growing global market, these companies are well-positioned to thrive in the coming years. As they continue to evolve and adapt to industry challenges, roll former machine manufacturers will undoubtedly contribute to shaping the future of manufacturing, ensuring that quality and efficiency remain paramount in the production of metal products.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025