custom gutter machine

Understanding Custom Gutter Machines A Comprehensive Overview

When it comes to effective water drainage and home protection, gutter systems play an indispensable role. A well-functioning gutter system directs rainwater away from the roof and foundation of a building, preventing water damage and other related issues. For contractors and builders, the demand for high-quality, custom gutters has led to the emergence of specialized tools custom gutter machines. These machines automate the production of gutters, allowing for greater efficiency and precision in creating tailored solutions for varied architectural needs.

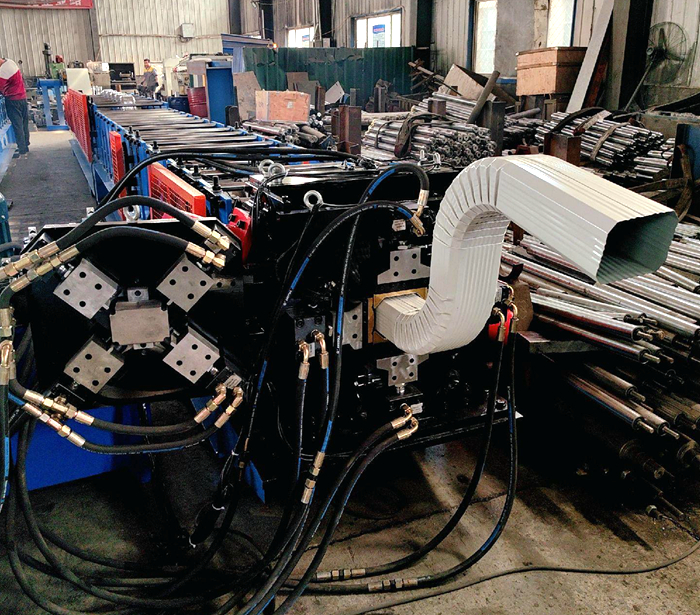

Custom gutter machines are designed to produce seamless gutters on-site, reducing wastage and ensuring a perfect fit. This adaptability is particularly important given the diverse architectural styles and sizes of buildings that contractors encounter. Traditional gutter solutions often come in standard sizes, which may not cater to specific building requirements. Custom gutter machines eliminate that limitation, enabling the creation of gutters that meet exact specifications.

The core advantage of utilizing a custom gutter machine lies in its ability to fabricate gutters from a variety of materials, including aluminum, copper, and steel

. Each material has its benefits aluminum is lightweight and resistant to corrosion, copper offers aesthetic appeal and longevity, and steel is known for its strength. Contractors can choose materials based on the client’s budget, the local climate, and the desired durability of the installation.custom gutter machine

Additionally, customization options extend beyond just material selection. These machines can create gutters in various styles, such as K-style, half-round, or box gutters. Different styles suit different architectural designs, ensuring that the gutters not only perform effectively but also complement the building’s aesthetic. The ability to create custom miters and end caps on-site significantly enhances the overall finish of the gutter system, leading to a more professional appearance.

In terms of operational efficiency, modern custom gutter machines incorporate advanced technologies, such as computerized controls and digital measuring systems. These features streamline the setup and execution process, minimizing the chance for human error. Furthermore, many machines are designed to be mobile, allowing contractors to transport them easily to job sites. This mobility is a significant advantage, as it enables the production of gutters where they are needed, cutting down on transportation costs and time delays.

Investing in a custom gutter machine can be the turning point for contractors looking to expand their service offerings and enhance job profitability. By producing tailored gutter solutions, they can fulfill demands for high-quality installations, attract a wider client base, and ultimately increase their competitive edge in the market. As effective drainage solutions become ever more crucial in home and building maintenance, the reliance on custom gutter machines is likely to grow.

In summary, custom gutter machines represent a revolution in how gutter systems are fabricated and installed. They combine efficiency, customization, and quality, ensuring that contractors can meet diverse project needs. As the construction industry continues to evolve, embracing advanced machinery like custom gutter machines may be key to maintaining relevance and achieving success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025