Feb . 02, 2025 00:52

Back to list

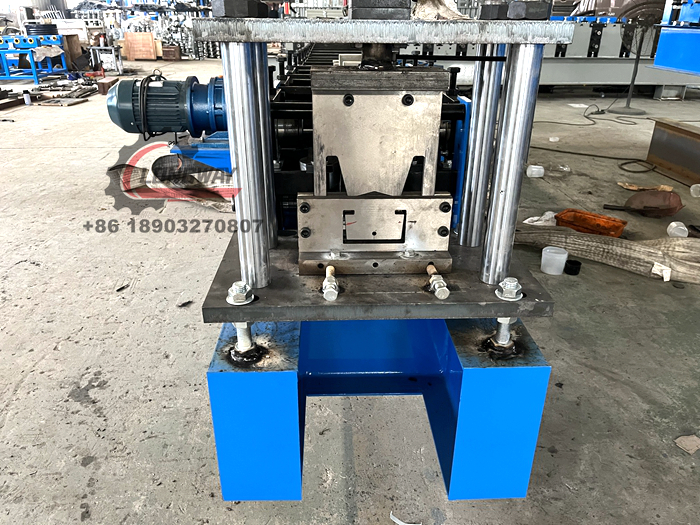

rain gutter roll forming machine

When it comes to enhancing the longevity and performance of rain gutters, investing in a high-quality rain gutter roll forming machine is paramount. These sophisticated devices revolutionize the production process of rain gutters, offering unparalleled precision and efficiency that caters to both commercial and residential needs. This article aims to explore the myriad benefits of these machines through real-world experiences, professional insights, and authoritative viewpoints, underpinning their trustworthiness in the industry.

The authoritativeness of rain gutter roll forming machines is bolstered by their rigorous compliance with international standards for quality and safety. Many manufacturers send their machines through exhaustive testing processes to receive certifications such as ISO 9001. Industry reports have documented the significant improvements in performance and durability of rain gutters formed by these machines. Perhaps the most compelling reason for their authoritative stance in the market is the feedback from long-term users who report fewer issues related to leaks and structural integrity in gutters manufactured through roll forming technology. Trustworthiness, on the other hand, is often built on the manufacturer’s reputation and the machine's proven track record. Manufacturers like New Tech Machinery and Englert have established themselves as pioneers in the field due to their continuous innovation and customer-centric approach, often offering extensive warranties and customer support services. Client testimonials often reflect the machines' reliability and quality, reinforcing trust in the purchase decision. In conclusion, rain gutter roll forming machines are not just a purchase, but an investment in quality and efficiency. Through the experiences of professionals like James Miller and George Thompson, the expertise evident in machine flexibility and automation, the authoritative nature validated by international standards, and the trust fostered by leading manufacturers—these machines are indispensable for businesses seeking to provide superior gutter solutions. Embracing this technology not only enhances operational efficiency but also solidifies a company's competitive edge in the dynamic construction industry landscape.

The authoritativeness of rain gutter roll forming machines is bolstered by their rigorous compliance with international standards for quality and safety. Many manufacturers send their machines through exhaustive testing processes to receive certifications such as ISO 9001. Industry reports have documented the significant improvements in performance and durability of rain gutters formed by these machines. Perhaps the most compelling reason for their authoritative stance in the market is the feedback from long-term users who report fewer issues related to leaks and structural integrity in gutters manufactured through roll forming technology. Trustworthiness, on the other hand, is often built on the manufacturer’s reputation and the machine's proven track record. Manufacturers like New Tech Machinery and Englert have established themselves as pioneers in the field due to their continuous innovation and customer-centric approach, often offering extensive warranties and customer support services. Client testimonials often reflect the machines' reliability and quality, reinforcing trust in the purchase decision. In conclusion, rain gutter roll forming machines are not just a purchase, but an investment in quality and efficiency. Through the experiences of professionals like James Miller and George Thompson, the expertise evident in machine flexibility and automation, the authoritative nature validated by international standards, and the trust fostered by leading manufacturers—these machines are indispensable for businesses seeking to provide superior gutter solutions. Embracing this technology not only enhances operational efficiency but also solidifies a company's competitive edge in the dynamic construction industry landscape.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products