Versatile C/Z Purlin Roll Forming Machine for Efficient Production and Quick Adjustments

Quick Changeable C/Z Purlin Roll Forming Machine A Modern Solution for Structural Steel Fabrication

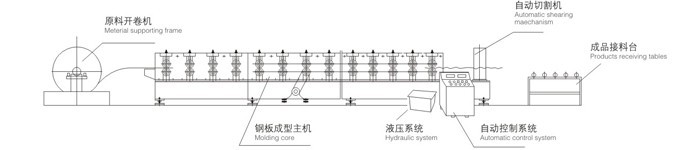

In the ever-evolving landscape of construction and manufacturing, efficiency and versatility are paramount. One of the most revolutionary innovations in this arena is the quick changeable C/Z purlin roll forming machine. This sophisticated piece of equipment is designed to streamline the production of C and Z purlins used in various structural applications, addressing the growing demands of the industry for both speed and adaptability.

Understanding Purlins

Before diving into the capabilities of the roll forming machine, it’s essential to understand what purlins are. Purlins are horizontal beams used in the construction of roofs and walls, providing essential support and stability. They are typically made of steel and come in two primary shapes C-shaped and Z-shaped. The choice between these shapes depends on specific structural requirements, load conditions, and overall design considerations.

The Role of Roll Forming Technology

Roll forming is a continuous bending process in which sheet metal is passed through a series of rolls to obtain the desired cross-section shape. The versatility of this method makes it ideal for producing C and Z purlins with high precision and consistency. However, traditional roll forming machines often require significant downtime for changes between designs, which can lead to delays in production and increased costs.

Features of Quick Changeable Machines

The quick changeable C/Z purlin roll forming machine is engineered to overcome these limitations. Some of its key features include

1. Rapid Changeover The standout attribute of this machine is its ability to change from C to Z purlin production with minimal downtime. This is achieved through a user-friendly mechanism that allows operators to reconfigure the machine quickly and efficiently, accommodating the various profiles without extensive manual intervention.

2. High Efficiency The machine is designed for high-speed production while maintaining high-quality output. With advanced automation and streamlined processes, manufacturers can produce large quantities of purlins in a fraction of the time compared to conventional systems, significantly boosting productivity.

quick changeable c/z purlin roll forming machine

3. Precision Engineering Equipped with CNC (Computer Numerical Control) technology, these machines ensure accuracy in dimensions, tolerances, and consistency across each product. This precision is crucial for the structural integrity of buildings and other construction projects.

4. Versatile Material Handling The ability to handle various materials, including galvanized steel, pre-painted steel, and other alloys, makes this machine a versatile tool for manufacturers. This flexibility allows businesses to meet diverse project requirements and adapt to market demands.

5. User-Friendly Interface Many modern systems come with intuitive control panels and touchscreen interfaces, making operation straightforward even for less experienced workers. This ease of use reduces the training time required for operators and enhances overall efficiency.

Benefits to the Industry

The implementation of quick changeable C/Z purlin roll forming machines presents numerous benefits to the construction and manufacturing sectors

- Cost Savings By reducing production downtimes and improving material yield, these machines help businesses cut operational costs significantly.

- Faster Project Turnaround With the capability to switch between product types rapidly, construction projects can proceed at a faster pace, meeting tight deadlines and increasing client satisfaction.

- Sustainability Efficient production methods also contribute to sustainability by minimizing waste and optimizing resource use, aligning with the industry's growing focus on environmentally responsible practices.

Conclusion

In conclusion, the quick changeable C/Z purlin roll forming machine represents a significant advancement in manufacturing technology. Its ability to efficiently produce high-quality purlins while offering versatility and rapid changeover capabilities positions it as an invaluable asset for any construction and fabrication business. As the industry continues to embrace innovation, investing in such advanced machinery will undoubtedly yield long-term benefits and maintain competitiveness in a dynamic market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025