t shape purlin roll forming machine

Understanding T-Shape Purlin Roll Forming Machines

In the world of metal fabrication, the efficiency and precision of production processes play a crucial role in determining the final quality of products. One of the most significant developments in this arena is the T-shape purlin roll forming machine. This sophisticated piece of equipment is essential for producing T-shaped purlins, which are integral components in the construction industry, particularly in steel structures.

What are T-Shape Purlins?

T-shape purlins are structural components used to support roofing and wall systems. They have a unique shape that offers high strength and rigidity, making them ideal for various applications in industrial and commercial buildings. These purlins serve as the backbone of many structures, providing stability and supporting loads effectively. The T-shape design helps distribute weight evenly and reduces material stress, thereby enhancing the overall durability of buildings.

Features of T-Shape Purlin Roll Forming Machines

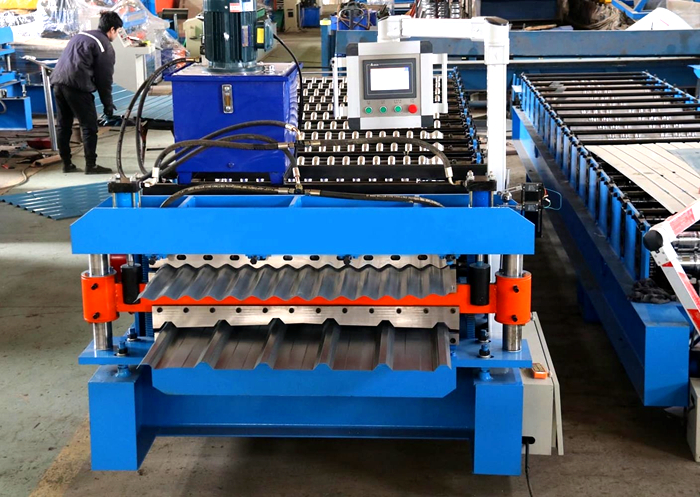

T-shape purlin roll forming machines are engineered for efficiency and precision. These machines utilize a continuous process to transform flat metal sheets into shaped purlins. The primary features of these machines include

1. High Production Efficiency The roll forming process allows for fast production rates, which is crucial for large-scale projects. These machines can produce a vast quantity of purlins in a relatively short time.

2. Customization Many roll forming machines are equipped with adjustable settings, enabling the production of purlins in various sizes and specifications. This flexibility allows manufacturers to meet specific client requirements without the need for extensive retooling.

3. Precision Engineering The advanced technology used in T-shape purlin roll forming machines ensures that each product meets strict dimensional tolerances. This accuracy is essential for structural integrity and proper installation.

5. Automated Control Systems Many modern machines come with advanced automation features, allowing operators to monitor and control the production process easily. This reduces the likelihood of human error and enhances overall efficiency.

t shape purlin roll forming machine

The Manufacturing Process

The manufacturing process using a T-shape purlin roll forming machine typically involves several key steps

1. Feeding Flat metal sheets are fed into the machine, where they are aligned for processing.

2. Forming The metal passes through a series of rollers that gradually shape it into a T-profile. The precision of the rollers ensures that the dimensions are consistent.

3. Cutting Once the metal is formed, it is cut to the desired length. This step can be automated, further increasing efficiency.

4. Final Inspection Quality control checks are performed to ensure that the purlins meet specified tolerances before they are packaged for delivery.

Applications in Construction

T-shape purlins are widely used in industries such as agriculture, warehousing, and industrial construction. They are often employed in the construction of steel buildings, storage facilities, and even residential structures. Their ability to provide reliable support makes them a popular choice among builders and architects alike.

Conclusion

In conclusion, T-shape purlin roll forming machines represent a significant advancement in metal fabrication technology. Their efficiency, precision, and versatility make them indispensable tools in the production of T-shape purlins, which play a vital role in the construction industry. As technological advancements continue to evolve, the capabilities of these machines will likely expand, further enhancing their impact on building construction and design. The future of the construction industry will depend heavily on such innovations, driving efficiency while maintaining structural integrity in modern architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025