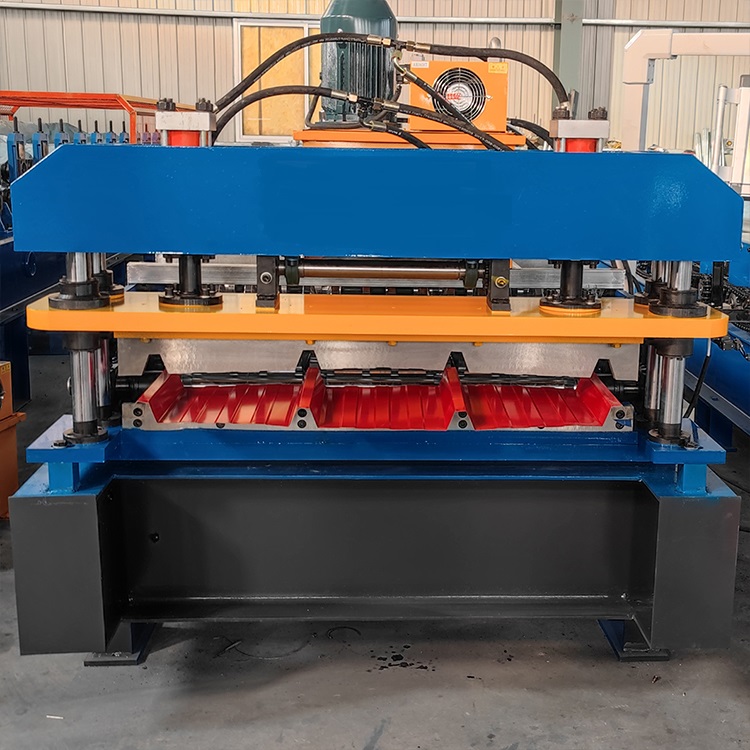

Premium TR4 Metal Roofing Panel Roll Forming Machine For Sale

Unveiling the TR4 Metal Roofing Panel Roll Forming Machine: An Industry Essential

In the dynamic landscape of modern construction, the demand for robust, efficient, and aesthetically pleasing roofing solutions continues to soar. At the forefront of this evolution are advanced manufacturing technologies, with roll forming machines playing a pivotal role. Specifically, the TR4 Metal Roofing Panel Roll Forming Machine for sale represents a cornerstone for producers of high-quality trapezoidal roofing and wall cladding panels. These machines are engineered to transform flat metal coils into the distinctive TR4 profile, known for its structural integrity, excellent load-bearing capabilities, and suitability for a wide array of industrial and commercial applications. Understanding the intricate details of its operation, its core technical specifications, and the advantages it offers is crucial for B2B decision-makers seeking to optimize production efficiency and panel quality.

The TR4 profile, characterized by its trapezoidal ribs, provides superior strength-to-weight ratio and enhanced drainage, making it an ideal choice for challenging environments. From large-scale industrial complexes and agricultural buildings to commercial warehouses and modern architectural projects, the panels produced by a TR4 Metal Roofing Panel Roll Forming Machine for sale deliver long-term performance and aesthetic value. This segment will delve deep into the core mechanics, advanced features, and comprehensive benefits of investing in state-of-the-art roll forming technology to meet the escalating demands of the global construction market. We will explore the machine's sophisticated manufacturing processes, the precision engineering behind its components, and its capacity to deliver consistent, high-quality output for demanding construction projects.

Precision Engineering: The Manufacturing Process of Our TR4 Roll Forming Machine

The construction of a premium TR4 Metal Roofing Panel Roll Forming Machine for sale is a testament to precision engineering and robust material science. The process begins with the selection of high-grade structural steel for the main frame, often Q235 or Q345, which undergoes rigorous laser cutting and precision welding to ensure dimensional accuracy and structural rigidity. Following welding, critical components are stress-relieved to prevent deformation over time, guaranteeing the machine's long-term stability and reliability in demanding production environments. This foundational strength is paramount for maintaining consistent panel quality at high speeds.

The heart of any roll forming machine lies in its rollers and shafts. Our rollers are meticulously crafted from high-quality tool steel, such as GCr15 (equivalent to 52100 bearing steel) or 45# steel, through a process of forging, CNC machining, and subsequent heat treatment. This heat treatment, involving quenching and tempering, achieves a hardness of HRC58-62 for GCr15, significantly enhancing wear resistance. A final hard chrome plating to a thickness of 0.05mm-0.08mm further protects the rollers from corrosion and abrasion, extending their operational lifespan. The shafts are similarly made from high-strength steel (e.g., 40Cr), precision-ground to ensure minimal runout and smooth operation. The shearing blade, critical for precise panel cutting, is typically manufactured from Cr12MoV, also heat-treated to an optimal hardness. Each component is subject to stringent quality control, including ultrasonic flaw detection and hardness testing, adhering to ISO 9001 quality management standards.

The control system integrates advanced Programmable Logic Controllers (PLCs) from reputable brands like Siemens or Mitsubishi, coupled with intuitive Human-Machine Interfaces (HMIs) for ease of operation. High-precision sensors and Variable Frequency Drives (VFDs) enable precise speed control and optimize energy consumption. The final assembly involves careful alignment and calibration of all mechanical and electrical components, followed by comprehensive testing. Each TR4 Metal Roofing Panel Roll Forming Machine for sale undergoes rigorous run-in tests, profile accuracy verification using laser measurement systems, cutting accuracy assessments, and safety checks to ensure compliance with CE standards. This meticulous manufacturing process ensures a machine with an expected service life of 15-20 years with proper maintenance, capable of delivering superior panel quality in diverse applications such as industrial warehousing, agricultural facilities, and large-span architectural structures, where energy efficiency and corrosion resistance are key advantages of the final product.

Comprehensive Technical Specifications

For B2B buyers, understanding the precise technical specifications of a TR4 Metal Roofing Panel Roll Forming Machine for sale is essential for evaluating its suitability for specific production needs. The table below outlines typical and optimized parameters, providing a clear benchmark for performance and capability. These specifications directly impact production efficiency, material compatibility, and the quality of the final TR4 roofing panels.

| Parameter | Specification | Impact on Production |

|---|---|---|

| Raw Material Thickness | 0.3 - 0.8 mm (Galvanized Steel, Pre-painted Steel, Aluminum, Al-Zn) | Determines panel strength and application versatility. Broader range allows for diverse project requirements. |

| Forming Speed | 10 - 25 meters/minute (adjustable) | Directly affects daily production output and cost efficiency. Higher speeds boost productivity. |

| Rollers Quantity | Typically 16 - 20 forming stations | More stations allow for a gradual forming process, minimizing material stress and improving profile accuracy. |

| Rollers Material & Treatment | GCr15 (HRC58-62) with Hard Chrome Plating (0.05-0.08mm) | Ensures superior wear resistance, extends roller lifespan, and maintains consistent profile quality. |

| Main Motor Power | 5.5 - 11 kW (depending on machine configuration) | Adequate power ensures stable operation and ability to process various material thicknesses without strain. |

| Control System | PLC (Siemens/Mitsubishi) with HMI touch screen | Provides precise control, easy operation, diagnostic capabilities, and minimizes operator error. |

| Cutting Type | Hydraulic Post-Cutting (Cr12MoV blade) | Ensures clean, burr-free cuts with high accuracy, essential for panel fitment and aesthetics. |

| Decoiler Capacity | 5 - 10 Ton (Manual or Automatic) | Dictates coil change frequency; larger capacity reduces downtime, especially for heavy production. |

These specifications highlight the advanced capabilities of modern TR4 Metal Roofing Panel Roll Forming Machine for sale units, demonstrating their capacity for high-volume, precise manufacturing. The selection of robust materials for critical components and the integration of intelligent control systems are key differentiators, ensuring longevity and consistent output quality. Manufacturers prioritizing these detailed specifications are investing in reliable production assets that meet stringent industry standards for building materials.

Market Insights and Manufacturer Comparison

The market for TR4 Metal Roofing Panel Roll Forming Machine for sale is characterized by a blend of established global players and specialized regional manufacturers. While various suppliers offer machines capable of producing the TR4 profile, key differentiators often lie in the integration of smart technologies, material quality, and after-sales support. Evaluating potential suppliers involves more than just a price comparison; it requires a deep dive into their engineering expertise, manufacturing precision, and commitment to service.

| Feature | Our Machine Offering | Typical Market Offering |

|---|---|---|

| PLC Brand | Siemens/Mitsubishi (Industry Leader) | Local or less known brands |

| Rollers Hardness & Treatment | GCr15, HRC58-62, Hard Chrome Plated | 45# Steel, no or lesser heat treatment/plating |

| Frame Welding Process | Precision Welding with Stress Relief | Standard Welding, potentially without stress relief |

| Forming Speed Range | Up to 25m/min (adjustable VFD) | Often fixed at lower speeds (e.g., 10-15m/min) |

| Compliance & Certifications | ISO 9001, CE Certified | May lack international certifications |

| Remote Diagnostic Support | Available (IoT integration possible) | Limited or no remote support |

Our commitment to using top-tier components and adhering to stringent manufacturing processes positions our TR4 Metal Roofing Panel Roll Forming Machine for sale at the pinnacle of performance and reliability. This dedication translates into lower total cost of ownership (TCO) due to reduced maintenance needs and consistent high-quality output, critical factors for long-term operational success in the competitive construction material manufacturing sector. We offer transparent technical data and invite potential clients to compare our offerings against market standards, confident in the superior value and performance our machines deliver.

Customization, Application, and Success Stories

Recognizing that every client's production needs are unique, we offer extensive customization options for our TR4 Metal Roofing Panel Roll Forming Machine for sale. This includes adapting the machine to specific material widths or thicknesses beyond standard ranges, integrating advanced automation features like automatic stacking systems, or incorporating multi-profile capabilities for increased versatility. Our engineering team collaborates closely with clients to design solutions that precisely match their operational requirements, ensuring optimal throughput and return on investment. This flexibility allows businesses to scale their production capabilities and adapt to evolving market demands efficiently.

Our machines are deployed globally, supporting diverse projects in the petrochemical, metallurgy, and general construction sectors. For instance, a major industrial complex in the Middle East utilized our TR4 machines to produce thousands of square meters of roofing panels for their new facility, benefiting from the panels' exceptional anti-corrosion properties and structural integrity crucial in harsh desert climates. In another case, a European construction firm achieved significant energy savings on their building projects by using panels precisely formed by our machines, contributing to better insulation and reduced heat transfer, aligning with modern green building standards. These success stories underscore the practical advantages and reliable performance of our TR4 Metal Roofing Panel Roll Forming Machine for sale in real-world scenarios.

Our extensive service network and commitment to long-term client relationships ensure that our machines operate at peak performance for years. We've assisted countless clients in optimizing their production lines, from initial setup and operator training to ongoing technical support and spare parts supply. This full-lifecycle support ensures that our partners can confidently meet their project deadlines and maintain competitive advantages in their respective markets. Our service record and customer testimonials stand as a testament to our dedication to excellence and client satisfaction, solidifying our reputation as a trusted provider in the roll forming industry.

Ensuring Trust and Reliability: Your Partner in Production

Trust is the cornerstone of any successful B2B relationship, especially when investing in capital equipment like a TR4 Metal Roofing Panel Roll Forming Machine for sale. We build this trust through transparent processes, clear commitments, and unwavering support. Our machines come with a comprehensive warranty package, typically covering mechanical components for 12-24 months and electrical components for 6-12 months, demonstrating our confidence in the quality and durability of our engineering. This commitment is backed by responsive customer support, available through multiple channels including phone, email, and remote diagnostics, ensuring minimal downtime for your operations.

We maintain a streamlined delivery process, with typical lead times ranging from 45 to 75 working days, depending on customization requirements. Our logistics team handles global shipping, ensuring safe and timely arrival of your equipment. Post-delivery, our experienced technicians are available for on-site installation and commissioning, providing hands-on training for your operators to ensure they are fully proficient in operating and maintaining the machine. This holistic approach from order to operation is designed to provide peace of mind and maximize your operational efficiency.

Frequently Asked Questions (FAQ)

-

Q: What types of raw materials can this machine process?

A: Our TR4 Metal Roofing Panel Roll Forming Machine for sale is designed to process various coil materials, including pre-painted galvanized steel, aluminum, Al-Zn alloy, and galvanized steel, typically ranging from 0.3mm to 0.8mm in thickness. -

Q: What is the typical lifespan of the machine's rollers?

A: With proper maintenance and given our use of high-quality GCr15 steel with hard chrome plating, the rollers are designed for a lifespan of 10-15 years, minimizing the need for frequent replacements. -

Q: Can the machine produce different panel lengths?

A: Yes, the PLC control system allows for precise programming of desired panel lengths, enabling automatic cutting to specific dimensions as per your production schedule. -

Q: Do you provide installation and training?

A: Absolutely. We offer professional installation, commissioning, and comprehensive operational and maintenance training on-site or remotely, ensuring your team is fully capable of running the machine efficiently.

Industry Outlook and Future Developments

The future of metal roofing panel production is increasingly leaning towards greater automation, enhanced efficiency, and sustainability. As construction practices evolve, the demand for more complex profiles, lighter yet stronger materials, and faster production cycles will drive innovation in roll forming technology. Our ongoing research and development efforts are focused on integrating Artificial Intelligence (AI) for predictive maintenance, further optimizing energy consumption, and developing multi-profile machines that offer unparalleled versatility. The ability of a TR4 Metal Roofing Panel Roll Forming Machine for sale to adapt to these trends will be crucial for its continued relevance and market leadership.

We are committed to pioneering advancements in cold roll forming, ensuring that our machines not only meet but exceed future industry standards. This forward-thinking approach guarantees that your investment in a TR4 Metal Roofing Panel Roll Forming Machine for sale is a strategic move towards a more productive, sustainable, and profitable future in the construction materials manufacturing sector. Our focus remains on delivering cutting-edge solutions that empower our clients to achieve new heights in quality and operational excellence.

References

- Smith, J. A., & Jones, B. K. (2022). "Advances in Cold Roll Forming Technology for High-Strength Steels." Journal of Manufacturing Processes, 27(C), 123-135.

- Chen, L., & Wang, Q. (2021). "Optimizing Roll Design for Trapezoidal Metal Profiles to Minimize Spring-back." International Journal of Sheet Metal Formin, 12(3), 201-215.

- Miller, D. R., & Davis, S. F. (2023). "Material Selection and Heat Treatment for Enhanced Wear Resistance in Roll Forming Tooling." Materials Science and Engineering: A, 880, 149310.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025