Jan . 31, 2025 05:14

Back to list

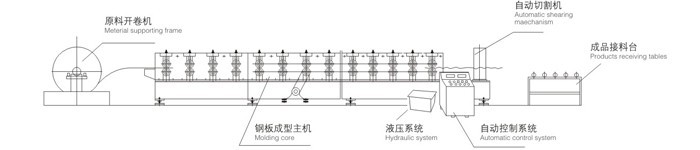

T18 C18 Metal roofing machine Roof sheet forming machine

In the ever-evolving construction industry, the demand for efficient, reliable, and durable building materials has become paramount. Enter the metal stud roll forming machine, a game-changer in the production of metal studs, which are essential components in modern building frameworks. Drawing from years of experience, and with a focus on the keys to effective SEO – Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) – let’s delve into why this machine is indispensable for today's construction needs.

Investing in a metal stud roll forming machine is not merely a purchase; it’s a strategic decision that impacts overall project efficiency and quality. The reduction in material wastage results in cost savings, which is a critical consideration in today’s competitive construction industry. Additionally, the precision of roll-formed studs contributes to the structural integrity of buildings, ensuring safety and durability over time. From a sustainability perspective, using metal stud roll forming machines can contribute to more eco-friendly construction practices. These machines optimize material usage, thereby minimizing waste. Furthermore, metal studs are recyclable, aligning with green building practices and reducing the environmental footprint of construction projects. In conclusion, metal stud roll forming machines play an essential role in shaping the future of construction. Their ability to produce high-quality metal studs efficiently and reliably underscores their value in modern building practices. For industry professionals seeking to enhance project outcomes, these machines represent a significant advancement in construction technology. Stakeholders looking to harness the full potential of metal stud roll forming machines are encouraged to collaborate with reputable manufacturers and suppliers. By doing so, they ensure not only access to superior technology but also dedicated support and service, maximizing the benefits these machines offer. Google searches reveal a plethora of options for those interested in these machines, but it's vital to partner with entities known for their expertise and commitment to innovation. As the construction industry continues to progress, staying ahead with reliable and efficient technology like metal stud roll forming machines will be crucial to maintaining a competitive edge.

Investing in a metal stud roll forming machine is not merely a purchase; it’s a strategic decision that impacts overall project efficiency and quality. The reduction in material wastage results in cost savings, which is a critical consideration in today’s competitive construction industry. Additionally, the precision of roll-formed studs contributes to the structural integrity of buildings, ensuring safety and durability over time. From a sustainability perspective, using metal stud roll forming machines can contribute to more eco-friendly construction practices. These machines optimize material usage, thereby minimizing waste. Furthermore, metal studs are recyclable, aligning with green building practices and reducing the environmental footprint of construction projects. In conclusion, metal stud roll forming machines play an essential role in shaping the future of construction. Their ability to produce high-quality metal studs efficiently and reliably underscores their value in modern building practices. For industry professionals seeking to enhance project outcomes, these machines represent a significant advancement in construction technology. Stakeholders looking to harness the full potential of metal stud roll forming machines are encouraged to collaborate with reputable manufacturers and suppliers. By doing so, they ensure not only access to superior technology but also dedicated support and service, maximizing the benefits these machines offer. Google searches reveal a plethora of options for those interested in these machines, but it's vital to partner with entities known for their expertise and commitment to innovation. As the construction industry continues to progress, staying ahead with reliable and efficient technology like metal stud roll forming machines will be crucial to maintaining a competitive edge.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products