Top Manufacturers of Metal Stud Roll Forming Machines for Construction Industry

The Essential Guide to Metal Stud Roll Former Manufacturers

In the modern construction landscape, the demand for metal stud roll formers is on the rise, driven by the need for lightweight, durable, and cost-efficient building materials. Metal stud framing has become a staple in residential and commercial projects alike, favored for its ease of installation and versatility. This article delves into the world of metal stud roll former manufacturers, highlighting their significance, technological advancements, and the factors to consider when choosing a supplier.

Understanding Metal Stud Roll Forming

Metal stud roll forming machines are designed to convert flat metal sheets into C-shaped or U-shaped studs, used primarily in drywall construction. The process involves feeding metal coils through a series of rollers that progressively shape the material into the desired stud profile, followed by cutting it to length. These roll formers can produce various sizes and gauge metal studs, catering to a range of construction needs.

Importance of Quality Manufacturers

When selecting a metal stud roll former, the manufacturer plays a crucial role in ensuring the quality and reliability of the end product. Established manufacturers often adhere to strict quality control measures to ensure that their equipment meets industry standards. Investing in machines from reputable manufacturers minimizes the risk of production issues, which can lead to costly project delays.

Key Factors to Consider

1. Technology and Innovation The best roll former manufacturers continuously innovate their technology. Look for companies that utilize advanced design software and automation features to increase efficiency and precision. Modern machines should also include options for quick changeovers between stud sizes, improving production versatility.

2. Customization Options Every construction project has unique requirements. It is essential to choose a manufacturer that offers customizable solutions, allowing for tailored roll forming systems that meet specific project needs. This flexibility can significantly enhance productivity and reduce waste.

3. After-Sales Support Reliable after-sales support is crucial for long-term operational efficiency. Manufacturers should provide comprehensive service packages, including installation, training, and ongoing maintenance support. A strong warranty must also be in place to protect your investment against manufacturing defects.

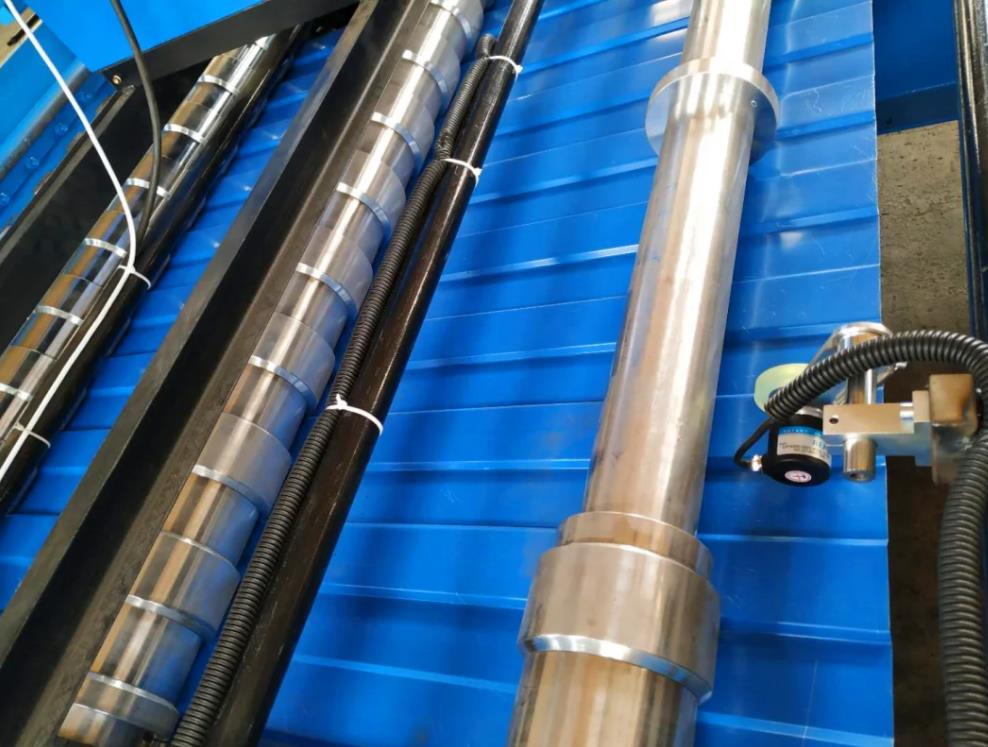

metal stud roll former manufacturers

4. Reputation and Experience Research the manufacturer’s reputation in the industry. Companies with extensive experience and positive customer feedback typically have proven themselves in terms of reliability and quality output. It can be beneficial to seek out testimonials and case studies from existing clients.

5. Affordability and Financing While high-quality equipment may come with a higher initial investment, it pays off in the long run through lower maintenance costs and enhanced productivity. However, it’s essential to compare prices and seek manufacturers who offer financing options, making it easier for businesses to acquire the necessary machinery without straining their budgets.

Leading Manufacturers

Several manufacturers stand out in the metal stud roll former market. They have established themselves through innovation, quality, and excellent customer service

- CW Warrant Known for their robust and high-efficiency roll forming machines, CW Warrant offers a range of customizable options suitable for various construction applications.

- Purlin Mill This manufacturer focuses on developing versatile roll formers, including those for metal studs. Their machines are known for durability and high-speed production capabilities.

- United Roll Forming With a strong emphasis on customer satisfaction, United Roll Forming is recognized for its comprehensive support and tailored solutions, making them a go-to for many contractors.

- Fasteel Renowned for their innovative design and technology, Fasteel's roll formers ensure precision and quality, leading to better productivity in metal stud production.

Conclusion

In conclusion, the choice of metal stud roll former manufacturers can significantly impact the success of your construction projects. By considering factors such as technology, customization, after-sales support, and the manufacturer’s reputation, you can ensure that you invest in equipment that meets your specific needs. Quality roll forming machinery not only boosts productivity but also contributes to the longevity and sustainability of your construction endeavors. As the demand for metal stud framing continues to grow, aligning with a reputable manufacturer will position your business for success in an evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025