Cost Analysis for Roll Forming Machines by Leading Manufacturers in 2023

The Cost of Roll Forming Machines An Overview for Companies

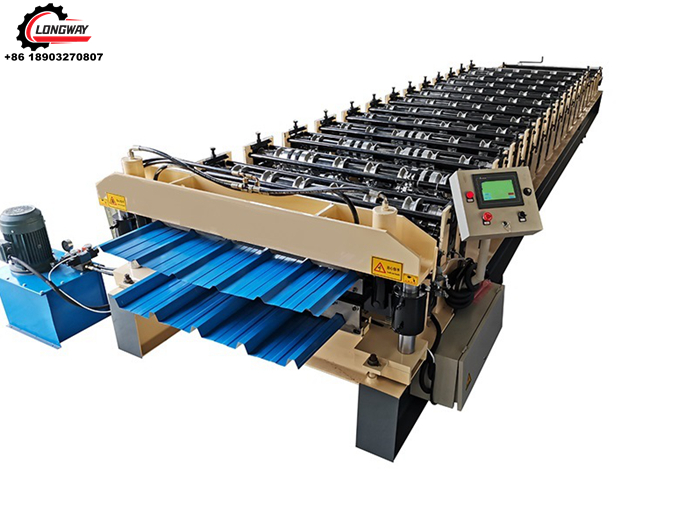

Roll forming, a continuous bending operation, is an essential manufacturing process widely used for producing various types of metal profiles and components. Industries such as construction, automotive, and appliance manufacturing rely heavily on this technology. However, when considering the adoption of roll forming machines, companies must carefully evaluate their costs and the return on investment (ROI) they can expect.

Initial Costs

The initial cost of acquiring a roll forming machine can vary significantly depending on several factors. On average, companies can expect to invest anywhere from $20,000 to over $500,000 for a new machine. Key determinants of this price range include the complexity of the die design, the size and thickness of the material being formed, and the machine's overall capacity. For businesses specializing in high-volume production, investing in a higher-end machine may be justified as it can lead to greater efficiencies and lower operational costs in the long run.

Operating Costs

Beyond initial purchase costs, a company must also consider the operational costs associated with running a roll forming machine. These include labor, maintenance, energy consumption, and overhead expenses. Efficient machines, which use less power and require fewer maintenance interventions, can significantly reduce these ongoing costs. Therefore, investing in a reliable machine with good energy ratings can yield long-term savings.

Labor costs can also impact the total cost of ownership. Depending on the machine's automation level, companies might need fewer operators, which can reduce labor costs significantly. Automated roll forming machines, while initially more expensive, often pay off by minimizing labor needs and increasing production rates.

Tooling and Die Costs

The production of different profiles requires specific tooling and dies, which can be a substantial expense. On average, tooling costs can range from a few hundred to several thousand dollars, depending on the complexity and size of the die required. Companies should weigh the costs of producing multiple profiles against the expenses associated with different tooling setups. Investing in a versatile machine capable of producing various profiles can provide flexibility and potentially lower die costs.

roll forming machine cost company

Return on Investment (ROI)

When evaluating the costs of roll forming machines, calculating potential ROI is crucial. A well-implemented roll forming line can radically increase a company's production efficiency by reducing waste, minimizing labor costs, and speeding up production times. For companies that produce high volumes of similar products, the ROI can be impressive. Many businesses report a payback period of 2 to 5 years, depending on the scale of operations and the efficiency of the machines utilized.

Additional Considerations

Aside from the direct costs associated with acquiring and operating roll forming machines, companies should also examine indirect costs such as training and integration into the existing production line. Employees will require training to operate new machinery efficiently, which can entail additional costs but is ultimately necessary for maximized productivity.

Moreover, firms should consider external factors such as market demand fluctuations, which can affect production volume and profitability. Purchasing equipment during a downturn could lead to underutilization, while rapid growth can strain existing capabilities.

Conclusion

Understanding the costs associated with roll forming machines is essential for companies looking to enhance their manufacturing capabilities. From initial investment and operational costs to ROI and indirect costs, a thorough analysis will help businesses make informed decisions. While roll forming can represent a significant expenditure, the potential for increased efficiency, reduced waste, and the ability to meet diverse production needs can make it a worthwhile investment in the long run.

As the industry evolves with technology, companies willing to adapt will find that investing in high-quality roll forming machines can offer both strategic advantages and substantial cost savings.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025