metal stud making machine

The Evolution and Significance of Metal Stud Making Machines

In the ever-evolving landscape of manufacturing, the importance of precision and efficiency cannot be overstated. One of the remarkable innovations that has transformed the construction and metalworking industries is the metal stud making machine. These specialized machines have redefined how metal studs are produced, leading to both time savings and increased quality in construction projects.

Understanding Metal Studs

Metal studs are essential components used in various construction applications, particularly in framing drywalls, ceilings, and partitions. They serve as an alternative to traditional wooden studs, offering several advantages, such as better fire resistance, uniformity, and durability. The demand for metal studs has surged in recent years, driven by the increasing popularity of steel-frame construction and the rising need for sustainable building materials.

The Role of Metal Stud Making Machines

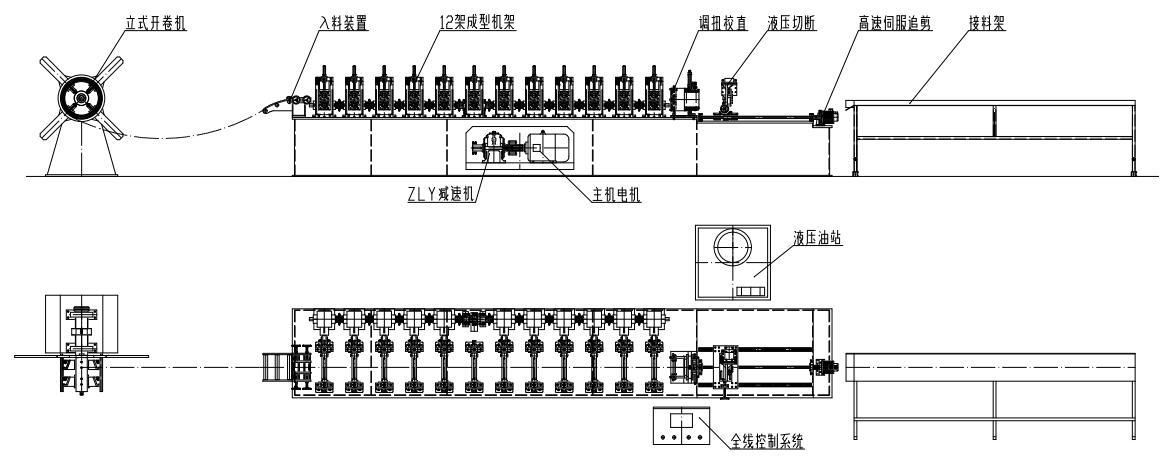

Metal stud making machines are specialized equipment designed to automate the process of manufacturing metal studs. These machines typically work with cold-rolled steel or galvanized steel, utilizing a series of processes that include cutting, bending, and welding to produce metal studs in different shapes and sizes. The automation of this process not only boosts production rates but also enhances the precision of the finished products.

Key Features of Metal Stud Making Machines

1. High Production Efficiency Modern metal stud making machines are equipped with advanced technology that allows for continuous operation. They can produce a large number of studs in a short period, meeting the demands of large-scale construction projects.

2. Precision Engineering These machines are designed to produce studs with high dimensional accuracy. Automated systems help minimize human error, ensuring that every stud meets strict specifications.

3. Versatility Metal stud making machines can be adjusted to produce various sizes and types of studs, enabling manufacturers to cater to diverse customer needs. This flexibility is crucial in a market that often requires customization.

4. Ease of Operation With user-friendly interfaces and automated controls, these machines can be operated with minimal training. This aspect allows companies to optimize their workforce and reduce training costs.

5. Durability and Reliability Built with high-quality materials and designed to withstand heavy workloads, metal stud making machines are known for their longevity and dependability in demanding production environments.

metal stud making machine

The Manufacturing Process

The production of metal studs typically involves multiple stages

1. Coil Preparation Metal coils are fed into the machine, which may have a de-coiler to straighten and position the material.

2. Cutting The machine cuts the material into specific lengths based on the desired stud measurements.

3. Forming The cut pieces are then formed into the desired shape. This may involve bending and shaping processes, where the metal is manipulated into the final stud configuration.

4. Welding In some cases, metal studs require welding to achieve additional strength. The machine may incorporate welding stations that fuse components together securely.

5. Finishing Finally, the finished studs undergo quality checks and surface treatments, such as galvanization, to enhance resistance to corrosion.

Future Trends

As technology advances, the metal stud making machine industry is witnessing several promising trends. Automation and Industry 4.0 principles are becoming integral, with machines increasingly integrated into smart manufacturing systems. Predictive maintenance techniques using IoT (Internet of Things) technologies are also being adopted to minimize downtime and enhance efficiency.

Furthermore, eco-friendly practices are gaining traction, with manufacturers exploring sustainable materials and energy-efficient processes to reduce their environmental footprint.

Conclusion

The metal stud making machine is a crucial player in the manufacturing landscape, bringing innovation and efficiency to the construction industry. As the demand for metal studs continues to rise, these machines will play an indispensable role in shaping the future of construction, ensuring that projects are completed on time and to the highest standards. With ongoing advancements in technology and manufacturing processes, the metal stud making industry is poised for a bright future, contributing significantly to modern architectural practices and sustainable building solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025